•Do not switch the function modes while the machine is operating.

Switching of the function modes during welding can damage the machine.

Damage caused in this manner will not be covered under warranty.

•Disconnect the electrode-holder cable from the machine before switching on the

machine, to avoid arcing should the electrode be in contact with the work piece.

•A safety switch is necessary to prevent the equipment from electric leakage.

•Welding tools and accessories should be of high quality and in good working order.

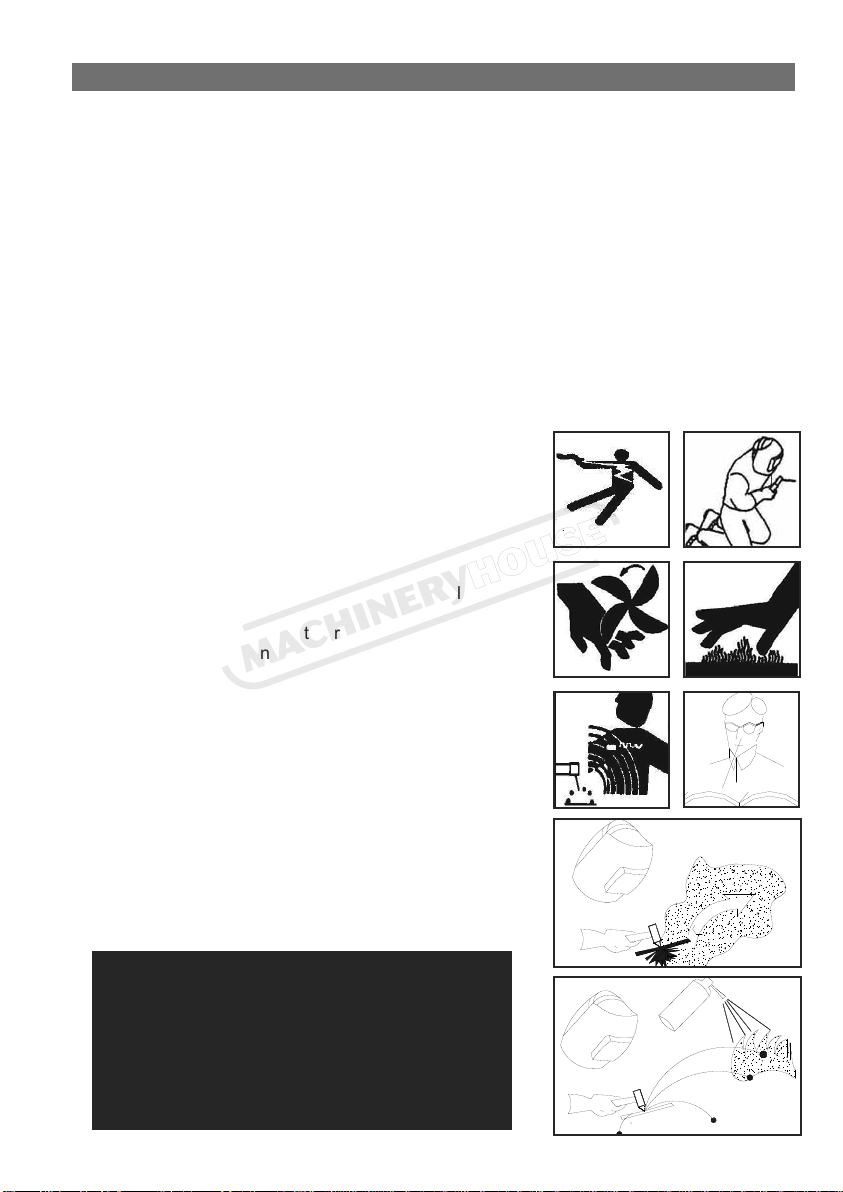

•Operators should be trained and or qualified. Electric shock: It can kill.

•Connect the primary input cable according to Australian standard regulation.

•Avoid all contact with live electrical parts of the welding circuit, electrodes and wires with

bare hands. The operator must wear dry welding gloves while he/she performs the

welding task.

•The operator should keep the work piece insulated from

himself/herself. Smoke and gas generated whilst welding

or cutting can be harmful to people’s health.

•Avoid breathing the smoke and gas generated whilst

welding or cutting. Keep the working area well ventilated.

•Arc rays are harmful to people’s eyes and skin. Always

wear a welding helmet and suitable protective

clothing including welding gloves whilst the welding

operation is performed.

•Measures should be taken to protect people in or near

the surrounding working area, from all hazards

associated with welding.

Fire hazard

•The welding sparks may cause fire, therfore remove

flammable material away from the working area.

•Have a fire extinguisher nearby, and have a trained

person ready to use it.

Noise: possibly harmful to people’s hearing.

•Noise is generated while welding/cutting, wear approved

hearing protection when noise levels are high.

Machine fault:

•Consult this instruction manual.

•Contact your local dealer or supplier for further advice.

SAFETY

Welding and cutting equipment can be dangerous to both the operator and people in or near the

surrounding working area, if the equipment is not correctly operated. Equipment must only be

used under the strict and comprehensive observance of all relevant safety regulations. Please

read and understand this instruction manual carefully before the installation and use/operation

of this equipment.

*** CAUTION ***

Do not heat, cut or weld tanks, drums or containers

until the proper steps have been taken to insure that

such procedures will not cause flammable or toxic

vapours from substance inside. These can cause

an explosion even though the vessel has been

“cleaned”.Vent hollow castings or containers before

heating, cutting or welding. They may explode.

Instruction Manual for ARC 170DC (W164)