OPERATING AND MAINTENANCE MANUAL KOS PREMIUM

- 4 -

Table of contents

PREFACE: .......................................................................................................................................................................... 5

1.

Precautions ............................................................................................................................................................... 5

1.1 Before you Begin to Use Your Machine ...................................................................................................... 5

1.2 Health and safety regulations ..................................................................................................................... 5

1.3 Servicing ...................................................................................................................................................... 6

1.4 Transport on highways................................................................................................................................ 7

1.5 Safety Symbols ............................................................................................................................................ 7

1.6 Nameplate ................................................................................................................................................... 9

2.

Technical and Identification Data ........................................................................................................................... 10

2.1 KOS PREMIUM / KOS PREMIUM LONG Specifications............................................................................... 12

3.

Operating Manual ................................................................................................................................................... 13

3.1 First Start ................................................................................................................................................... 13

3.2 Preparation of the Unit (Tractor + Machine) ............................................................................................ 13

3.3 Mounting and Disconnection of machines................................................................................................ 14

3.3.1

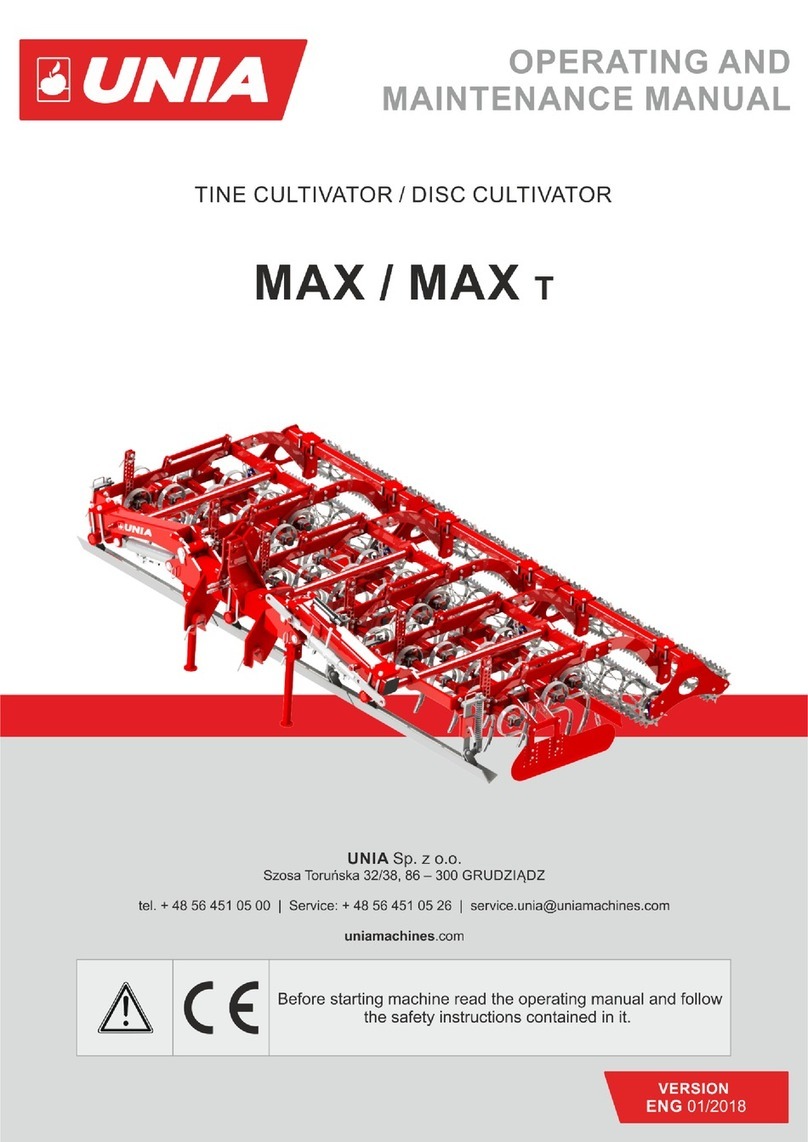

Mounted machines.............................................................................................................................. 14

3.3.2

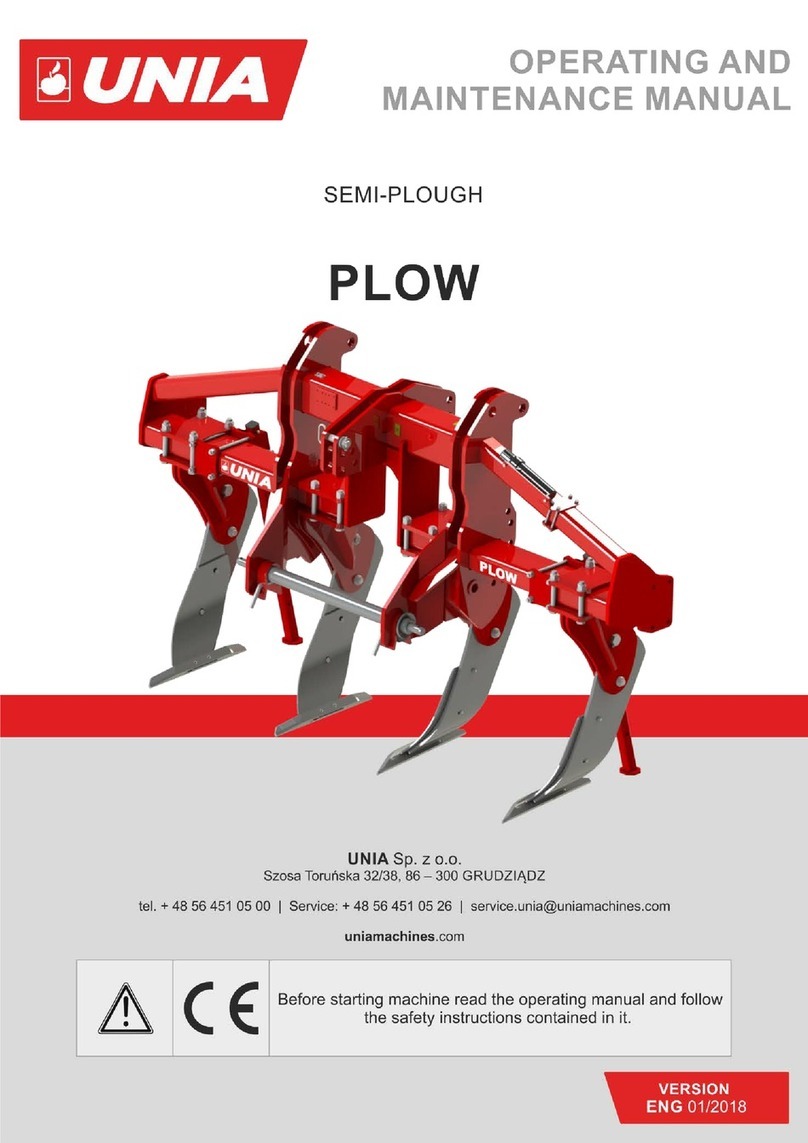

Semi-mounted machines..................................................................................................................... 15

3.4 Access to the Field – Transport ................................................................................................................. 16

3.4.1

Mounted machines.............................................................................................................................. 16

3.4.2

Semi-mounted machines..................................................................................................................... 17

3.5 Adjustment of the Cultivator..................................................................................................................... 18

3.5.1. Working Depth Adjustment - KOS PREMIUM...................................................................................... 18

3.5.2. Adjustment of the Working Depth of the KOS PREMIUM Disc Harrow Type A................................... 19

3.5.3. Extreme Disc Adjustment in the KOS PREMIUM/KOS PREMIUM LONG Harrow Type A and B ...... 19

3.5.4. Heavy-Duty Tine, Type CX.................................................................................................................... 20

3.5.5. Working Depth Adjustment -KOS PREMIUM LONG ............................................................................ 21

3.5.6. Adjustment of Scraping Disc Harrow Type B in the KOS PREMIUM, type A and B in the KOS PREMIUM

LONG ................................................................................................................................................... 23

4.

Operation (see par. II Safety) .................................................................................................................................. 24

5.

Servicing and Maintenance..................................................................................................................................... 24

5.1 General ...................................................................................................................................................... 24

5.2 Replacement of the Machine Components............................................................................................... 25

5.3 Hydraulic System....................................................................................................................................... 25

5.4 Lighting ...................................................................................................................................................... 25

5.5 Bolt, screw and nut tightening torques (Nm)............................................................................................ 25

5.6 Lubrication ................................................................................................................................................ 26

5.7 Storage of the Cultivator ........................................................................................................................... 28

5.8 Disassembly and Disposal ......................................................................................................................... 28

5.9 Warranty Conditions and Warranty Services............................................................................................ 28