6HT-Series | Version 1.01

Safety

Mususe

The lifting table must not be used for any improper pur-

pose! Misuse ofthe lift table is included, for example:

- Use in contravention of the regulations of the ope-

rating instructions,

- Use after unauthorized conversions or modificati-

ons,

- Exceeding the max. permissible load capacity,

- Enter the lift table,

- Transport or moving of persons with the lift table.

In case of misuse of the lift table, any warranty, liability

and other claims for damages of the operator against

the manufacturer are eliminated!

Modifications

Only use the lift table in its original condition, i.e. as sup-

plied!

The components of the lift table must not be changed in

their type and condition.

Use only spare parts (accessories) that comply with the

specifications in the spare parts list. Deviations are not

permitted!

Modifications or alterations by the operator without the

written consent of the manufacturer are prohibited and

eliminate all warranty, liability and other claims for da-

mages by the operator against the manufacturer!

2.6 General safety regulations

- During transport, storage, installation, commissioning,

operation, servicing, maintenance and troubleshoo-

ting of the lift table, compliance with the provisions of

these operating instructions must be observed.

- The lift tablee may only be operated in a safe and pro-

per condition. Its safe condition must be checked at

least once a year by qualified personnel.

- Only qualified trained persons who have been in-

structed in the handling of the lift table to carry out

work.

- Only qualified trained persons - minimum age 18

years - who are familiar with these operating instructi-

ons, in particular the safety regulations, should be au-

thorised to do the work.

- All other regulations on work safety and accident pre-

vention must be observed. The operator must issue

operating instructions.

Obligations of the staff

The following general safety regulations must be obser-

ved:

The operator is responsible for the safe use of the lift table!

- Defective or missing safety devices must be repai-

red or replaced immediately by a specialist! The

lift table must not be operated during this time!

- All activities which could endanger the safety of

man and machine must be prohibited!

- All regulations in these operating instructions must

be observed; the lift table may only be used for its

intended purpose and not improperly!

- In the case of faults, take the lift table out of opera-

tion, eliminate the cause of the fault, rectify the

fault, check the lift table for safe condition and only

then put it back into operation!

- The operator must ensure that no unauthorised

persons work on or with the lift table.

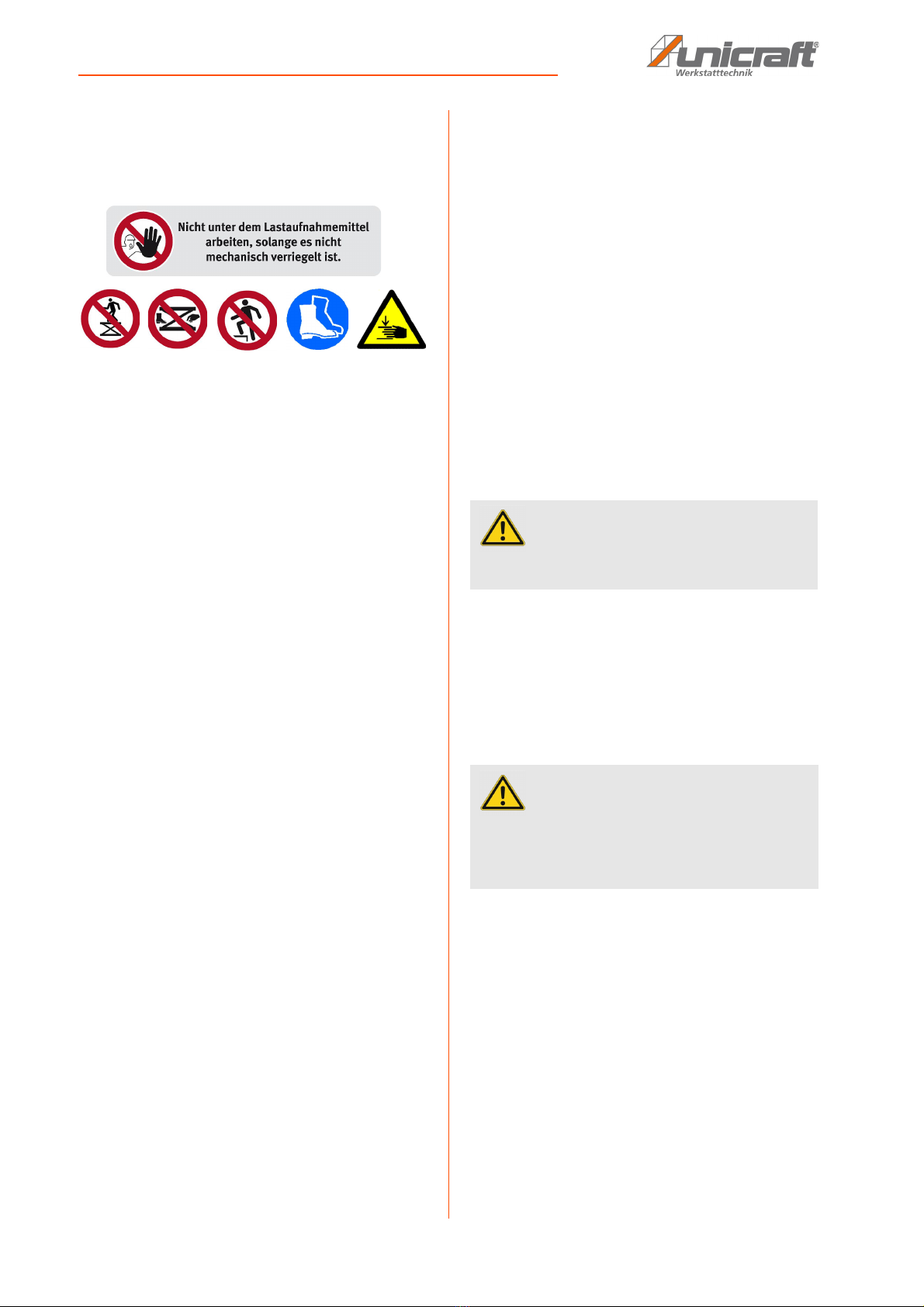

- It is not permitted to stand on load handling equip-

ment.The transport and lifting of persons is prohi-

bited.

- Set-up, modification, maintenance and inspection

work may only be carried out by trained person-

nel.

- It is noted that any unauthorised modifications and

alterations to the machine are not permitted for

safety reasons.

- In the case of hydraulic repairs to accumulator sy-

stems, the accumulator must be emptied before-

hand.

- The operating personnel must always ensure that

the maximum load capacity is not exceeded.

- Do not stand under a suspended load as loose ob-

jects can fall down at any time.

- It is forbidden to access the device if it has not

been secured by the maintenance support.