Unifiller Systems Inc. Page 2 of 48 Manual Part No.: MINI

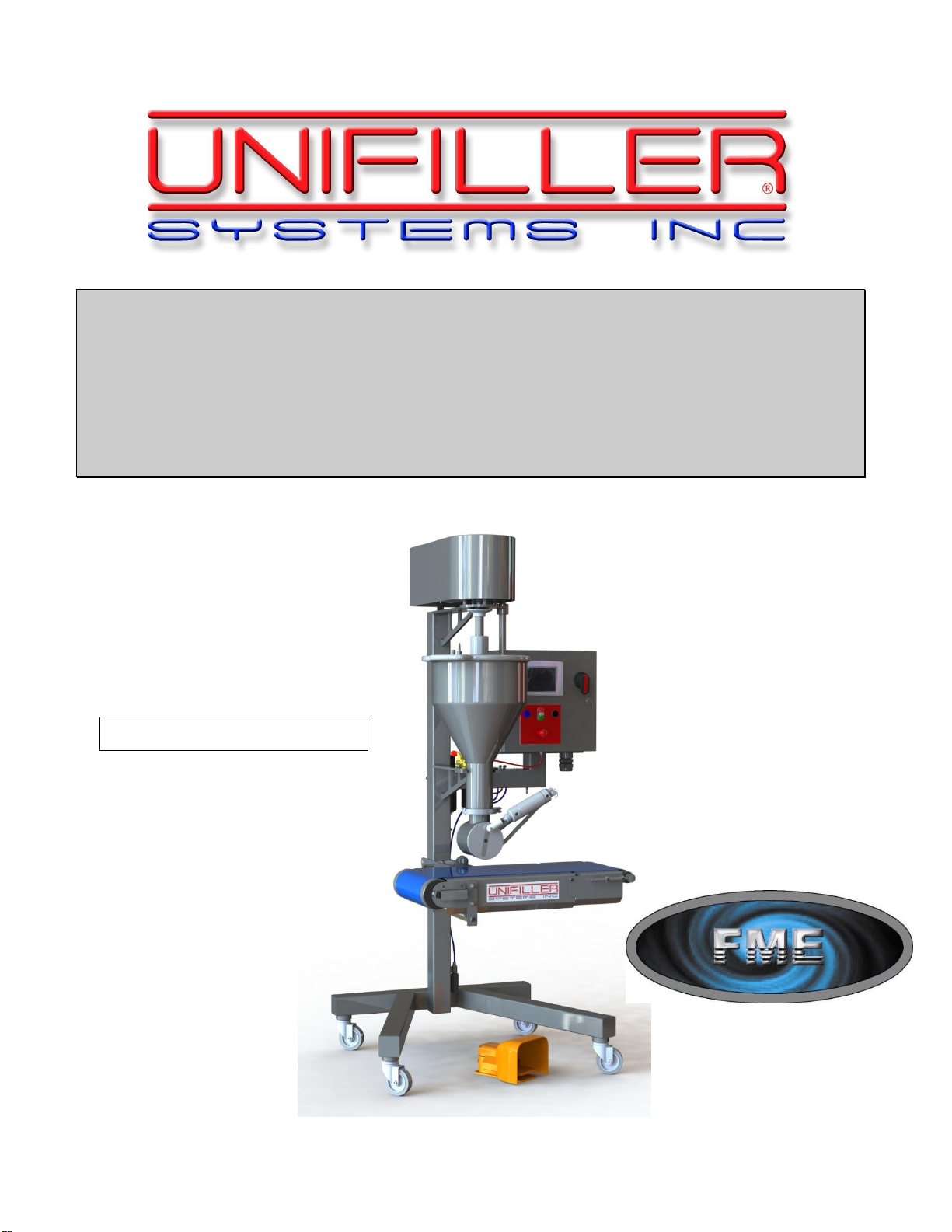

DOPOSITOR

TABLE OF CONTENTS

TABLE OF CONTENTS ......................................................................................................................................................2

INTRODUCTION .................................................................................................................................................................4

IMPORTANT SAFETY INFORMATION.........................................................................................................................5

OVERVIEW...........................................................................................................................................................................7

PRODUCT HANDLING............................................................................................................................................................7

DESIGN FEATURES................................................................................................................................................................7

MACHINE DESCRIPTION AND LAYOUT .....................................................................................................................8

UNPACKING AND INITIAL MACHINE SETUP.............................................................................................................9

POWER REQUIREMENTS ..............................................................................................................................................10

COMPRESSED AIR ...............................................................................................................................................................10

Air Pressure Adjustment................................................................................................................................................10

ELECTRICAL .......................................................................................................................................................................10

PRODUCTION SETUP & OPERATOR ADJUSTMENTS............................................................................................11

PRIMING /PREPARING TO DEPOSIT.....................................................................................................................................11

ADJUSTMENTS....................................................................................................................................................................11

OPERATION: .......................................................................................................................................................................11

CONTROLS LAYOUT.......................................................................................................................................................12

CONTROL BOX LAYOUT .....................................................................................................................................................12

DISASSEMBLY AND CLEANING...................................................................................................................................13

EMPTY PRODUCT FROM MACHINE......................................................................................................................................13

CLEANING ..........................................................................................................................................................................13

INSPECTION AND REASSEMBLY ..........................................................................................................................................14

CONVEYOR BELT TRACKING AND TIGHTENING..................................................................................................................14

SCREEN HIERARCHY...........................................................................................................................................................15

SCREEN HIERARCHY (CONT’D) ..........................................................................................................................................16

SCREEN HIERARCHY (CONT’D) ..........................................................................................................................................17

CONTROL SYSTEM DESCRIPTION.............................................................................................................................18

HELP SCREENS ...................................................................................................................................................................18

MAIN STARTUP SCREEN .....................................................................................................................................................19

MAIN STARTUP SCREEN CONTINUED….............................................................................................................................20

MINI DOPOSITOR SCREEN...................................................................................................................................................21

MINI DOPOSITOR MANUAL SCREEN ...................................................................................................................................22

STATISTICS SCREEN............................................................................................................................................................23

LOAD RECIPE SCREEN ........................................................................................................................................................24

SAVE RECIPE SCREEN.........................................................................................................................................................25

MODE SCREEN....................................................................................................................................................................26

CLEAN SCREEN...................................................................................................................................................................27

LOGIN SCREEN ...................................................................................................................................................................28

SYSTEM SCREEN.................................................................................................................................................................29

TECHNICAL SCREEN ...........................................................................................................................................................30