UnionSpecial 57100 Series Instruction sheet

Other UnionSpecial Sewing Machine manuals

UnionSpecial

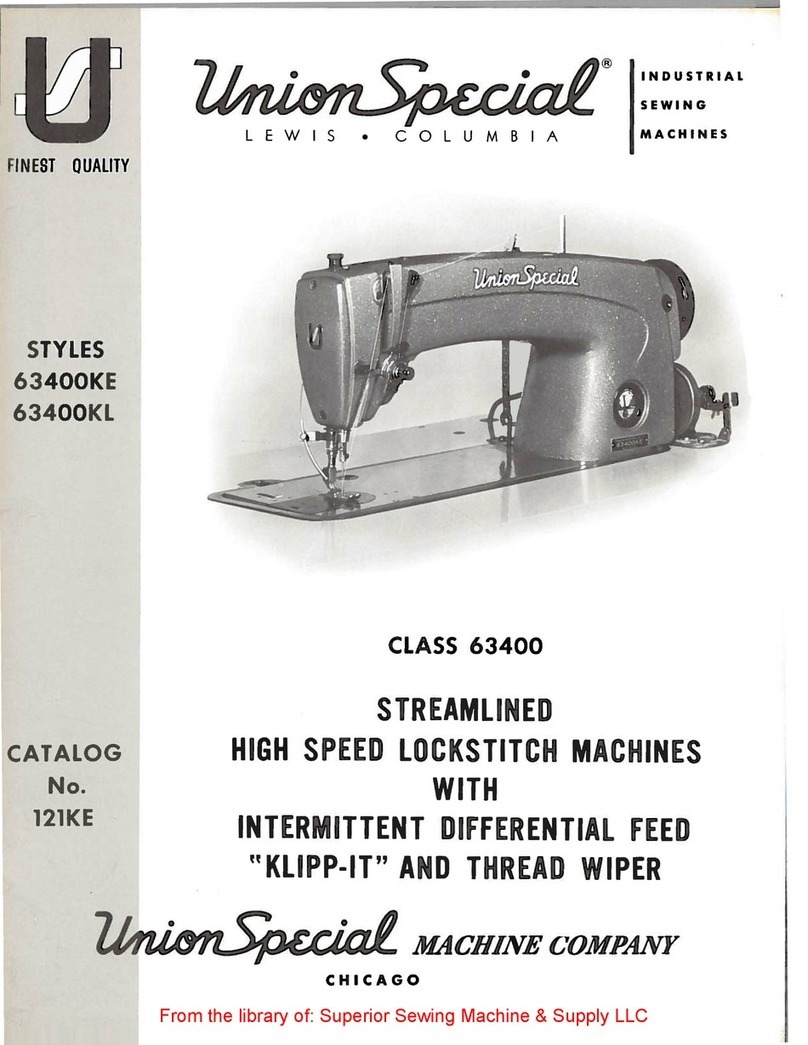

UnionSpecial 63400 Series Instruction sheet

UnionSpecial

UnionSpecial 81300A Setup guide

UnionSpecial

UnionSpecial 60000 D User manual

UnionSpecial

UnionSpecial 51300 Series Instruction sheet

UnionSpecial

UnionSpecial LF600 Series Setup guide

UnionSpecial

UnionSpecial 39500 Series Instruction sheet

UnionSpecial

UnionSpecial 39500 Series Instruction sheet

UnionSpecial

UnionSpecial 39500FW Instruction sheet

UnionSpecial

UnionSpecial 50000 Series Setup guide

UnionSpecial

UnionSpecial 39600 CU Instruction sheet

UnionSpecial

UnionSpecial 80800RN Setup guide

UnionSpecial

UnionSpecial CLASS 2200 User manual

UnionSpecial

UnionSpecial 39500 Series Instruction sheet

UnionSpecial

UnionSpecial 57700 Series Instruction sheet

UnionSpecial

UnionSpecial 3100A Datasheet

UnionSpecial

UnionSpecial 63900 Series Instruction sheet

UnionSpecial

UnionSpecial 398 Classic Series Setup guide

UnionSpecial

UnionSpecial 63400KE Instruction sheet

UnionSpecial

UnionSpecial G230A-GR Setup guide

UnionSpecial

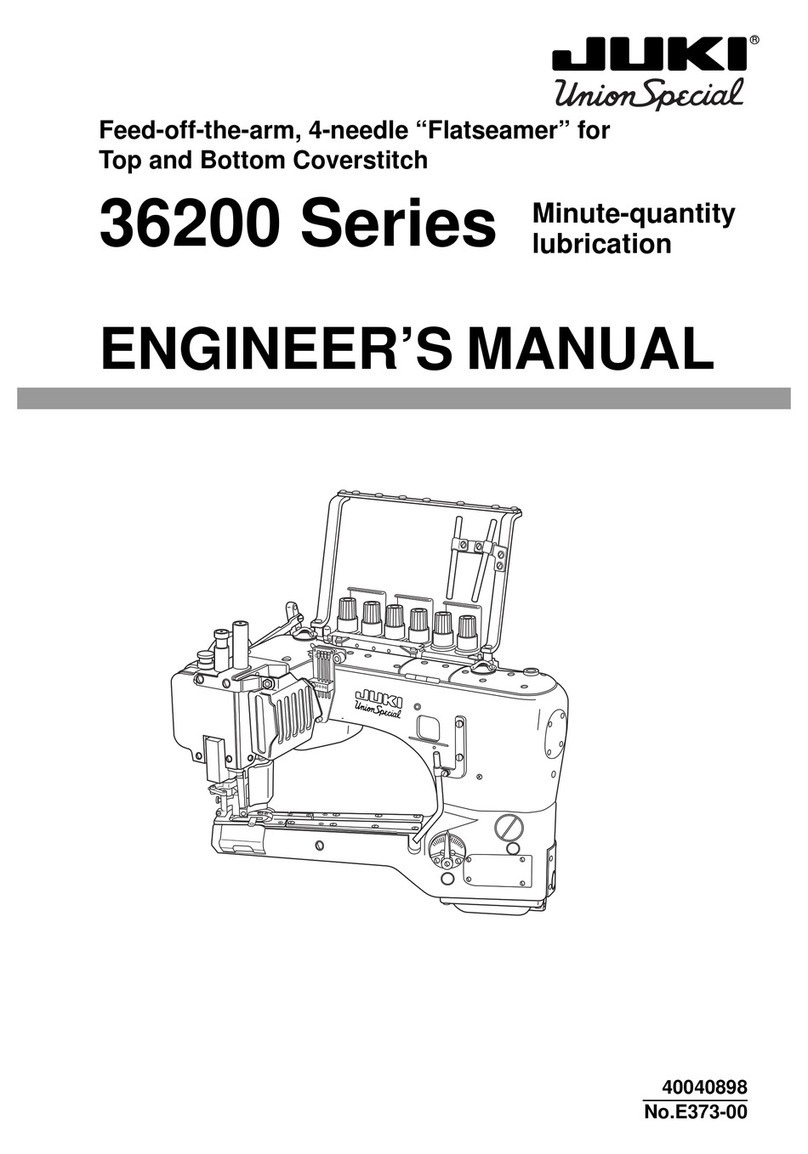

UnionSpecial Juki 36200 Series Quick start guide