FEED

ECCENTRICS

(Continued)

The

following

stitch

number

feed

eccentrics

are

available

under

No.

39540

B-4,

-5, -6, -7,

-8,

-

9,

-

10,-11,-12,-13,-14,-15,-16,-18,-20,-22.-24,-26,-28,-30,-32,

-

34,-36,

-

40.

Only

one

eccentric

is

supplied

with

each

machine.

Additional

eccentrics

may

be

ordered

separately.

To

order

an

eccentric,

use

No.

39540

B

with

a

minor

number

suffixed

to

indicate

approximately

the

number

of

stitches

desired.

Example:

11

39540

B-10".

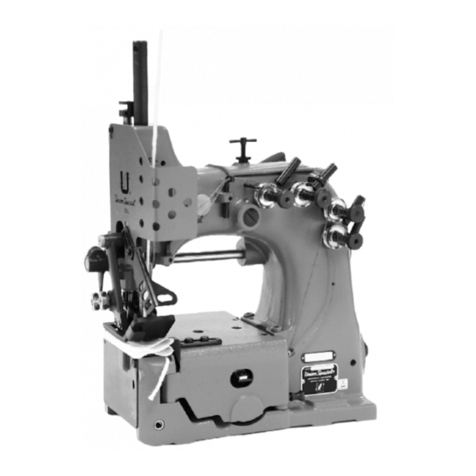

SETTING

THE

NEEDLE

With

the

throat

plate

(A,

Fig.

3)

assembled

in

position,

the

needle

arm

(B)

should

be

set

so

that

the

needle

enters

the

center

of

the

slot

in

the

throat

plate

and

at

high

position,

the

point

of

the

needle

should

be

set

7/

16

inch

above

the

top

surface

of

the

throat

plate

(Fig.

3).

This

can

be

accomp-

lished

by

loosening

screw

(C),

reposi-

tion

needle

driving

a;rm

as

required

and

retighten

screw.

Remove

the

throat

plate.

SETTING

THE

LOOPER

Fig.

3

The

looper

(A,

Fig.

4)

should

be

inserted

in

the

looper

holder

(B)

until

its

shank

contacts

the

looper

bar

(C)

and

should

be

set

so

the

flat

side

of

the

blade

is

parallel

with

the

looper

bar.

Tighten

screw

(D).

The

looper

holder

(A,

Fig.

5)

should

be

set

·

on

the

looper

bar

(B)

so

that

the

point

of

the

looper

is

5/64

inch

to

the

right

of

the

centerline

of

the

needle

when

the

looper

is

at

its

extreme

right

posi-

tion

(Fig.

5).

The

point

of

the

looper

must

barely

clear

the

back

of

the

needle

as

it

passes

to

the

left.

This

can

be

accomplished

by

loosening

screw

(

C,

Fig.

5),

reposition

looper

holder

as

required

and

retighten

screw.

The

needle

must

also

clear

the

backside

of

the

looper

on

the

downstroke

of

the

needle.

The

setting

as

outlined

in

the

first

paragraph

gives

the

maximum

amount

of

needle

clearance

behind

the

looper.

To

decrease

the

clearance

and

eliminate

skipping,

loosen

screw

(c.

Fig.

5)

and

move

holder

to

the

rear

and

then

loosen

screw

(D,

Fig.

4)

and

move

looper

point

forward

to

just

clear

the

needle

as

it

moves

to

the

left.

Retighten

screws.

SETTING

FRONT

NEEDLE

GUARD

Fig.

4

The

front

needle

guard

(D.

Fig.

5)

should

be

set

as

high

as

possible

without

interfering

with

the

looper

and

clear

the

closest

contacting

surface

of

the

needle

by

approximately

•

003

inch.

This

can

be

accomplished

by

loosening

screws

(E.

Fig.

5),

reposition

front

needle

guard

(D)

as

required

and

retighten

screws.

SETTING

REAR

NEEDLE

GUARD

The

rear

needle

guard

(F,

Fig.

5)

should

be

set

as

high

as

possible

without

interfering

with

the

needle

thread

loop

and

deflect

the

needle

•

002

to

•

005

inch

at

the

point

of

con

tact.

6

From the library of: Superior Sewing Machine & Supply LLC