Page 7

BLUESTREAK SERIES

INSTALLATION & OPERATING MANUAL

POWERING TECHNOLOGY

Document Number: BLUESTREAK-MAN Rev. 6 bluestreak-man-rev6-0719.indd

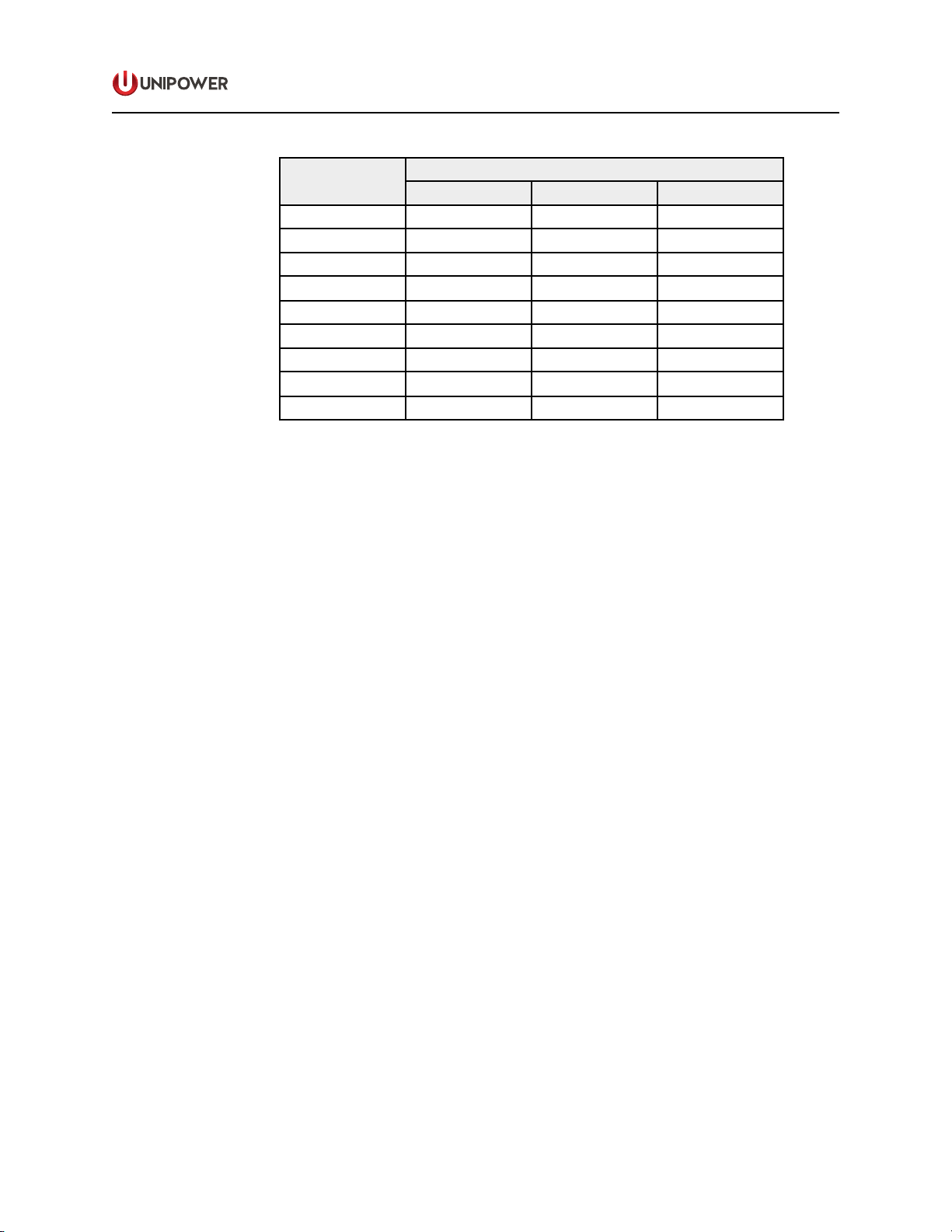

7.0 MODULE SPECIFICATIONS

The following specications are typical at 25°C unless otherwise noted.

INPUT

Voltage Range..................................................................See Model Table

Power Factor......................................................................................>0.98

Total Harmonic Distortion, Max.............................................................. 5%

Frequency......................................................................................47-63Hz

Inrush Current Limiting, Max. ..................................................... 50A Peak

EMI Filter, Conducted.......................................FCC20780 pt. 15J Curve B

.........EN55022

Curve B

Fast Transients......................................................................EN61000-4-4

Surges...................................................................................EN61000-4-5

Remote Adjust...............................................................................0 to +5V

Input Protection 1 ...........................................................Internal Fuse, 25A

OUTPUT

Current & Voltage........................................................................See Table

Output Power..........................................................................1200-2000W

Voltage Adjustment Range 2

48V / 54.4V.................................................................................30-60V

24V / 27.2V.................................................................................15-30V

12V / 13.6V................................................................................7.5-15V

Standby

Output

3.......................................................................

[email protected] .............

Line & Load Regulation, Max. ............................................................ 0.3%

Holdup Time ..................................................................................10msec.

Overvoltage Protection................................................................................

Latch O

Filtering: Wideband Noise, 20MHz BW........................................... 200mV

Current Limit 4..........................105-115% Rated Current (Programmable)

Eciency (54.4VDC @ 2000W rated)

100% Load ...............................................................................to 91.6%

75% Load ...............................................................................to 92.0%

40% Load ...............................................................................to 91.0%

SAFETY CERTIFICATIONS

UL60950-1 2nd Ed., CSA22.2 No. 60950-1 2nd Ed., EN60950-1 2nd Ed.

STATUS INDICATORS

STATUS.................................................................................... Green LED

FAULT...........................................................................................Red LED

ALARM SIGNALS (open drain, TTL compatible)

ACOK ................................................... AC present, 5V standby operating

DCOK.................................................... DC output within -10% of nominal

TEMPOK .................................................Internal temperature within limits

FANOK ....................................................................Fans running correctly

PM Bus

Version Compliance............................................................................... 1.1

ENVIRONMENTAL

Operating Temp. Range 5 ..................................................-20°C to +70°C

Output Current Derating......................................... 2.5%/°C, 50°C to 70°C

Storage Temp. Range........................................................ -40°C to + 85°C

Humidity........................................................0% to 95%, Non-Condensing

ESD..........................................Bellcore GR-1089-Core and EN61000-4-2

MTBF, 35oC (Bellcore)........................................................200,000 Hours

Cooling ..............................................................Integral Ball Bearing Fans

PHYSICAL SPECIFICATIONS

Case Material ......................................................................................Steel

Case Dimensions, Inches (mm) ....................... 1.60 H x 4.00 W x 13.70 D

......(40.6 x 102 x

347.9)

Weight ...............................................................................4.8 lbs. (2.2 kg.)

Notes:

1. External protection required when operating from HVDC.

2. When programmed via PMbus and may require adjusting DCOK and OVP settings.

3. Total standby power limited to 9.6W.

4. Subject to absolute power limit of 2000W + tolerance.

5. Startup at -40C, but output is not enabled until internal temperature reaches -20C

8.0 FRONT PANEL DESCRIPTION

Figure 2 - Front Panel Detail