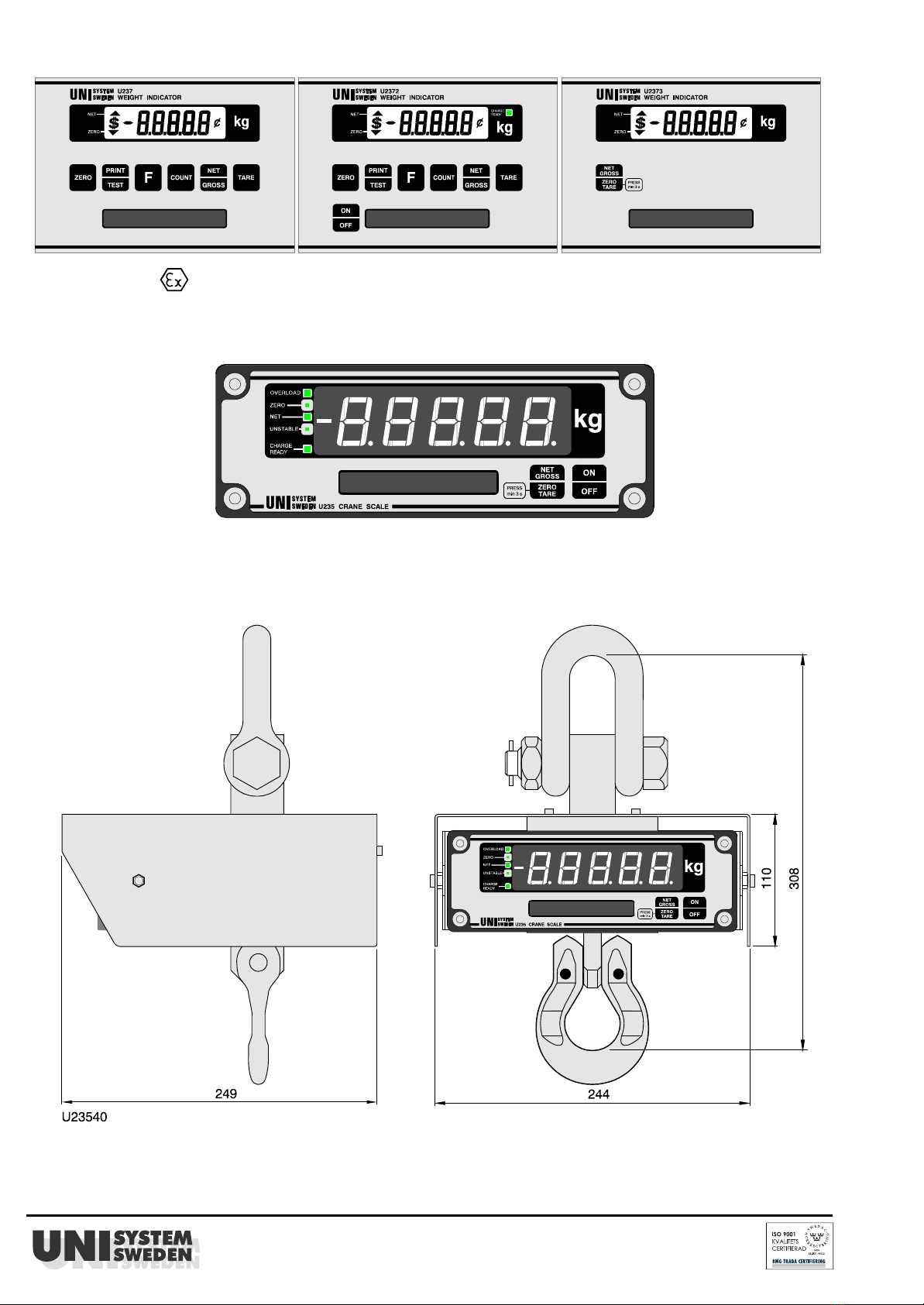

Calibration of U137, U235 & 237 Series Weight Indicators. Date:141027 B01950 5(10)

U2375 with optional tilt sensor U9027.

This indicator has 5 additional calibration steps, Cs28 to Cs32.

A cosine (square) compensation is made on the AD-value minus ADZ in Cs30. ADZ is the load cell AD-signal

without any load. AD-values < ADZ are not compensated.

A sine (linear) compensation may be entered for each direction in Cs31 and Cs32 respectively.

28 *=0 No tilt compensation. Only in U2375. P = pitch (Input PE5 on the processor) , R = roll (Input PE6).

=1 Max P and R = ±9.8° (17.0%). -9.8° = 0.026V, 0° = 1.315V, 9.8° = 2.604V. Standard tilt transducer U9027.

=2 As Cs28:1 but the display is blanked at 10% tilt. (Code =2 to =7 works only with program

=3 As Cs28:1 but the display is blanked at 8% tilt. dated 070207 or later)

=4 As Cs28:1 but the display is blanked at 7% tilt.

=5 As Cs28:1 but the display is blanked at 6% tilt.

=6 As Cs28:1 but the display is blanked at 5% tilt.

=7 The display is blanked at high on input PE4 on the processor in U2375

29 *=0 For the control of TARE and PRINT in e.g. automatic emptying equipment in refuse lorries.

=1 Tare signal at P = -9.4°. Stop at 4.7°, when the tare is not performed due to unstable signal.

Print signal at P = 9.4°. Stop at -4.7°, when the print is not performed due to unstable signal.

=2 As above but ±7.1° and ±3.0° respectively.

=3 As above but ±4.7° and ±2.4° respectively.

+4 Not used.

+8 Not used.

30 *29000 ADZ May be set from 1600 to 52600 in steps of 200.

ADZ corresponds to the AD-value without any load. The best way is to connect the load cells, tilted 90°, and enter

Cs30 before mounting. If the signal is outside the range, adjust with a high resistor between signal and excitation.

E.g. an ADZ, which is higher than correct value, results in too low tilt compensation. This negative error is inde-

pendent of load and constant, when tilted the same in all directions. It varies with the square (cosine) of the tilt angle.

Note! ADZ in Cs30 must always be entered before Cs31 & 32 . Else the adjustment is very difficult.

31

0.00 Tilt angle, P.

000000 AD-value.

P

±00000 Q

32

0.00 Tilt angle, R.

000000 AD-value.

R

±00000 Q

For compensation of linear (sine) errors, which change sign with angle.

Tilt angle and AD-value are indicated in sub step 1 and 2 respectively.

Q and sign are calculated from the formula below. This is done in both directions P and R.

The load receptor is tilted to equal positive and negative angles. The total change is )angle.

The AD-values are noted for zero angle and both tilts and used in the formula.

The calibration can not be left with S1 when displaying angle.

These errors are caused by different angle between tilt sensor and load cell(s) and by the side force sensitivity of

the load cell(s). Use a model with low side force sensitivity. Single point and shear beams, especially dual type, are

mostly good. (The side force is equal to the load times the tilt in percent.)

It is important that the load cell mounting is properly made. Multiple load cells bolted together, without any conve-

nient load transmission device, will have bad repeatability in the order of 0.1% or worse. The proper function of the tilt

compensation is then very difficult to measure and adjust.

Standard mountings from the load cell manufacturers are mostly not constructed for side forces.

Try to use load cells, which have small or at least equal side force sensitivity.

out out out

In order to get small change at eccentric loads, use current matched load cells (V /R = I equal).

Q and sign is calculated according to the following formula:

0 angle +angle -angle

Q @(AD-value - ADZ) @)angle @10 = AD-value - AD-value

-6

)= total change with positive sign.

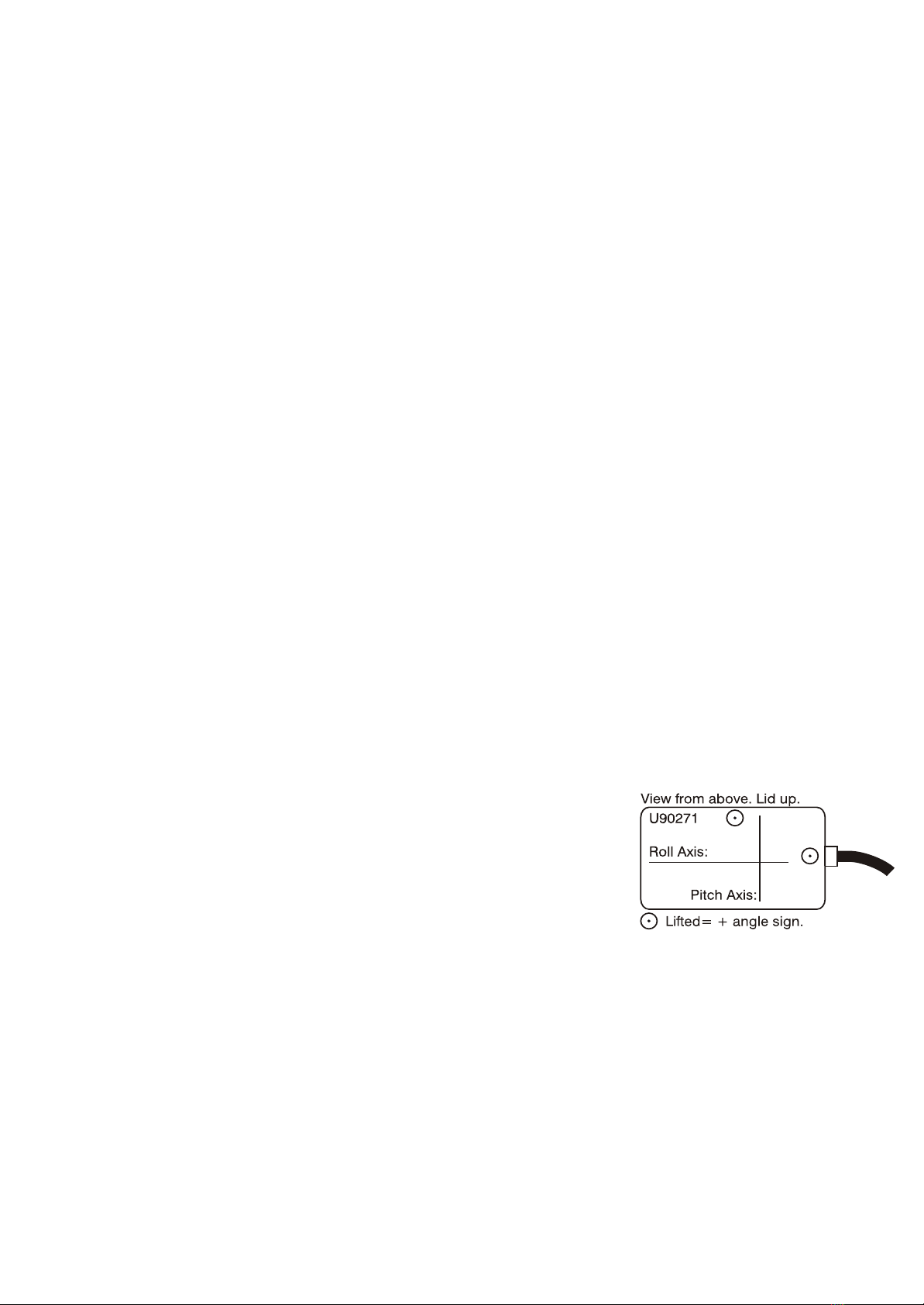

When the tilt transducer i s mounted according to the picture, a too high

+angle -angle

AD-value (and too low AD-value ) is compensated by a positive Q.

Keep the tilt position with weight loaded and enter Q. Leave the calibration

and check that the weight is properly compensated.

.

Example:

E.g. AD-values for -9°, 0° and +9° angle are 498200, 500000 and 502200.

The linear error is -2000 to +2000 units.

The square error is +200 AD-units, if present for P and R independent of load.

Then Cs30 is too low and an overcompensation is made. It must be increased by 200/(1-cos 9) = 16200 units..

Assume ADZ = 20000. Then Q@(500000 - 20000)@18 @10 = 502200 - 498200. Thus Q = +00463.

-6

Do never touch the potentiometers in the tilt transducer U90271.

Restrictions for verified scales. OIML R76-1 Ed. 92 (EN 45 501), paragraph number in ( ).

Cs01:=9 Should be used, when PT (Preset Tare) is used. (4.6.11). The reason for this and what shall be done with

the information is not mentioned.

Cs08:=5 Max 1 second. (4.4.1).

Cs09:+0 No printing at unstable weight. (4.4.5).

Cs11,12 Zero setting only minus weight (4.5.6). The reason for this is not mentioned. Zero tracking, max change

0.5 e/second. (4.5.7).

Cs19:+8 According to (4.10) for multiple range scales. For good load cells Cs20:=4 is an alternative.

Cs20:+8 According to (4.2.2.2 last paragraph) for multiple range scales. Reading difficult. Reason?

Cs23-25 Calibration weights (3.7.1), (3.7.3).

Cs24,25 Max +9e above verified max weight. (4.2.3).

Cs26,27 Gravity. WELMEC 2 Issue 3: 3.3.

Cs28 Tilt range. (3.9.1.1) says 5%. WELMEC 2 Issue 3: 3.1.13 says 10%.