Unitech UT-201 User manual

@

+91 7046223333 , 9427301436

www.utplindia.in

www

Model No. : UT-201

DUAL CHANNEL UNIVERSAL

PROCESS INDICATOR / CONTROLLER

INSTRUCTION MANUAL

M

96 x 96 Flame Proof

UT-201

M

COM

www.utplindia.in

RL-2

RL-1

RL-4

RL-3

201.0

201.0

UT-201

M

COM

www.utplindia.in

RL-2

RL-1

RL-4

RL-3

201.1

201.2

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

I

WARNING

Electrical Consideration / Precautions

The controller is considered “Rack and panel mounted equipment” per EN 61010-1, Safety Requirements for

electrical equipment for Measurement, Control and Laboratory Use, Part 1: General Requirements. Conformity

with 2/23/EEC Low Voltage Directive, requires the user to provide adequate protection against a shock hazard.

The user shall install this controller in an enclosure that prevents OPERATOR access to the rear terminals.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS INJURY.

Shielded twisted pair cable is required for all Analog Input & Output, Process Variables,

RTD, Thermocouple, DC volts-mV, low level signal, mA, Alarm Outputs, and Computer

communication interface circuits.

CAUTION

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PRODUCT DAMAGE.

Power Supply / Wiring Requirements

Applying 240V AC to a controller rated for 12-24VDC will severely damage the controller

and is a fire and smoke hazard.

This controller is suitable for connection to 230 + 15% VAC, 50 Hz or 12 / 24 VDC, power mains.

It is the user responsibility to provide the following

230 + 15% VAC - a switch, fuse (1/2A, 250V) or a circuit breaker.

12 / 24 VDC – a switch, fuse (1A, 125A) or a circuit breaker.

The above items should be installed together with UT-201 for the products electrical protection.

The switch, Fuse or circuit-breaker should be located close to the controller, within easy reach

operator. The switch or Circuit-breaker should be marked as the disconnecting device for the

controller. applying power to Multiple instruments, make sure that sufficient current is supplied,

Otherwise, the instruments may not start up normally due to the voltage drop caused by the in-

rush current.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PRODUCT DAMAGE.

Disposal action of Instruments follows as per country and regional law and rules & regulation also same in

international. Company might be follows as per rules.

DISPOSAL ACTION

PRE CAUTIONS, WARNING AND DISPOSAL ACTION

Line voltage Wiring

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

1

CONTENTS

2. INSTALLATION

2.1 MOUNTING

2.2 EXTERNAL DIMENSION

2.3 TECHNICAL SPECIFICATIONS

2.4 WIRING DIAGRAM

3. PROGRAMMING

3.1 OPERATION INTERFACE

3.2 MODE ACCESS FLOW CHART

4.1 CONFIGURATION MODE

4. OPERATIONAL MODES

4.2 SETUP MODE

4.3 CALIBRATION MODE

4.4 CHANGE PASSWORD MODE

4.5 ERROR MESSAGE.

5. COMMUNICATION [MODBUS RTU] PROTOCOL

5.1 INTRODUCTION

5.2 MODBUS CONFIGURATION BASIC SETTINGS

5.3 REGISTER ADDRESSES FOR MODBUS / RTU PROTOCOL

1. OVERVIEW

1.1 INTRODUCTION

2

2

2

2

2

3

4

5

5

6

7

7

9

10

11

11

12

12

12

12

12

5.4 MODBUS SYSTEM SCHEMATIC.

...................................................................................................

.........................................................................................

...................................................................................................

...................................................................................................

...................................................................................................

...................................................................................................

...................................................................................................

...........................................................................................

.............................................................................

....................................................................

...................................................................................

...........................................................................

............................................................................................

.................................................................................

.....................................................................

......................................................................................

...............................................

.........................................................................................

.............................................

...................................

.....................................................................

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

2

1.1 Introduction

Function

Mount Anywhere

The instrument can be configured for RTD or Thermocouple or Linear input by making changes in

configuration mode using 4 keys provided. This instrument can operate with full range for all inputs.

Unitech’s UT-201 Dual Channel Universal Indicator is designed to accept 2 Nos. thermocouple or RTD or

Linear Input and displays the process parameter through a dual set of 4 Digit Red LED Displays.

The instrument is available in a panel mounted housing which requires a cut out as per Panel cutout Dime-

- nsions given later . A variety of power supply options are available for this. The instrument has low drift

precision components for long trouble free operation. The instrument is a jumper less system. There are

different types of modes such as normal mode, operation mode, configuration mode, setup mode, and

change password mode. 4 keys provided can do any change in the mode.

Two different configuration levels provide easy access to parameters. A4 digit security code perverts una-

uthorized changes. Parameters can also be hidden to user to prevent improper configuration of the unit

The UT-201 product group is Process control instruments that must be panel mounted. The wiring terminals

must be provided. the UT-201 is environmentally hardened and, if suitably handled, can be mounted virtua-

-lly anywhere in plant or factory; in a panel or enclosure wall mounted or Flameproof enclosure or even on

the process machinery. it can withstand ambient temperature up to 50°C

Easy to Configure

1. OVERVIEW

2.1 Mounting

2.2 External Dimension

2. INSTALLATION

CAUTION

The product can be mounted on tilted or horizontal

panel using the mounting clamps supplied. Proper

space must be available at the back of the panel for

installation and maintenance activity.

Installation Mounting Precautions

FAILURE TO COMPLY WITH THESE INSTRUCTION MAY

RESULT IN INSTRUMENT DAMAGE

Side View

DIMENSION

Model A B D

CE

UT - 201

96 90

10 120

90+0.5

96 90+0.5 120

100

All dimensions are in mm

8.8.8.8.

100.0

UT-201

M

COM

www.utplindia.in

RL-2

RL-1

RL-4

RL-3

8.8.8.8.

100.0

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

3

Flame Proof

K : -50~1200˚C

R : 0~1750˚C

T : 0~400˚C

INPUT

RANGE

High scale / Low scale Full range as per input selection

General

Specificaion

Power Supply 110/240V AC, 50Hz, 12/24VDC [Optional on demand]

Power Consumption 4 Watts Maximum

Operating Ambient Temp. : 0~50˚C, Humidity : Below 90% Non condensing

Input

T/C K, J, R, S, T, E

RTD Pt-100, Pt-1000, Cu-53 [2 wire, 3 wire]

Linear : 4 ~20mA DC, 0~20mA DC, 0 ~5 Amp AC

CURRENT [Analog]

VOLTAGE [Analog]

Linear : 0.5~2.5VDC, 1~5VDC, 0~10VDC

SPECIAL ON DEMAND

Linear : 0~75m/0~200mVDC, 0~100/200/300VDC

Indication

Display Indication [Ch:1] : 0.56” 4 Digit [Ch:2]: 0.56” 4 Digit, 2 set 7 Segment Red Displays.

Relay Status Front Red LED for all Relay Alarm status

RTD Pt-100 : -50~400˚C

Linear All DC & AC : -1999~9999 Display

CURRENT [Analog]

VOLTAGE [Analog]

Linear All DC : -1999~9999 Display

SPECIAL ON DEMAND

Linear : -1999~9999 Display

T/C

Accuracy

T/C + 0.25% of Full Scale

RTD Class A

+ 0.1% of Full Scale

ANALOG [V & I]

SPECIAL ON DEMAND

+ 0.1% of Full Scale

Automatic Software based self compensation

Cold Junction Comp.

“OPEN” or “OVER” indication on display

Sensor Break Info.

AS per Input Range Table

Range Limits

>330 K for Voltage ,mV, and T/C, 100 R for current

Input Impedance

Status indication

Alarm modes

LEDs for Relay status & Communication

Low / High

Control Mode On Off control

Dead Band controls High and Low Set point for level application

Relay / SSR Max. : 2 Nos.[one for each channel]

Relay Output

SSR [Volt] Output

Retransmission

24VDC @ 20 mA ,12VDC @ 20 mA

Linear : 0~20/ 4~20 mA DC, 0~10 VDC

NO-C-NC Contacts , 5A@240 VAC Resistive, 2 Relays for each input

Other Output

Transmitter Power Supply : Isolated 24VDC@60mA ,Max.

Output

Prog. parameters

Modbus RTU RS- 485/RS- 232 Communication

Baud rate, Parity, Node address, Stop bit

Protocols & method

Max. Connections

Communication

Up to 128 Units

Programmable

Parameters

Display resolution

Setpoint / Hysteresis

Relay logic

Full range as per input selection

-1999 to 9999 fully configurable for each linear input

F.S. high & low alarm

Enclosure [If Reqd.] FC-1 [1-Compartment] OR FC-2 [2-Comp.] : IIA, IIB Exter. keys & Cable Entries

TECHNICAL SPECIFICATIONS

INPUT RANGE

J : -50~750˚C,

S : 0~1750˚C,

E : -50~400˚C,

2.3 Technical Specifications

Type of Input

[Ch-1 & Ch-2]

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

4

CAUTION

WIRING CONSIDERATION

Shielded twisted pair wire is used for all analog I/P, Process sensors RTD,

Thermo-couple, mV-mA DC, Volt DC, Linear input and Communication.

FAILURE TO COMPLY WITH THESE INSTRUCTION MAY RESULT

IN INSTRUMENT DAMAGE

CAUTION

LINE VOLTAGE

This product is suitable for connection 110/230VAC, 50Hz or 12/24 VDC main power

supply. It is user responsibility to provide proper protection for the products electrical

protection .

when applying power to various instruments, make sure sufficient current is supplied.

otherwise the instruments may not start up due to the Voltage drop.

FAILURE TO COMPLY WITH THESE INSTRUCTION MAY RESULT

IN INSTRUMENT DAMAGE

J / K / R / S / T / E

+

-

Shorng

19 20 21

-

THERMO-

COUPLE

B

RTD

PT-100 / 1000

19 20 21

BA

4 20mA / 0 20mA

~~

CURRENT[mA]

22 21

0 VDC5 /10

~

V

VOLTAGE

21

22

23

3 WIRE

21 22 98

T

mA Input TPS 24VDC

Transmier

TRANSMITTER

2 WIRE

21 22 98

T

mA Input TPS 24VDC

Transmier

TRANSMITTER

OUTPUT - RELAY, SSR

24VDC@20mA

12VDC@20mA

SSR-1

14 13

17 16

SSR-2

R-2

R-1

Relay Contact :

5A@240VAC

NC

C

NO

15 14 13

18 17 16

2.4 Wiring Diagram

RTD

VDC

21

20

19

24

25

D+

RS - 485

D-

NC

RELAY-2

NO CNC

NO C

RELAY-1

123456789

10

11

121314

A

B

B

TPS

24VDC

v

SUPPLY

E P

UT-201

15161718

N

T/C

mA

Noise

Filter

POWER

L

AC 230V, 50Hz

N

NOTE : 12VDC OR 24VDC SUPPLY CONTROLLERS ARE ALSO AVAILABLE ON DEMAND.

B

RTD

PT-100 / 1000

345

BA

J / K / R / S / T / E

+

-

Shorng

345

-

3 WIRE

5698

T

mA Input TPS 24VDC

Transmier

TRANSMITTER

2 WIRE

5698

T

mA Input TPS 24VDC

Transmier

TRANSMITTER

4 20mA / 0 20mA

~~

CURRENT[mA]

65

0 VDC5 /10

~

V

VOLTAGE

5

6

7

THERMO-

COUPLE

CH:1 INPUT

COMMUNICATION

RS-485

22 23

COMMNICATION

D+ D-

SUPPLY

230+15VAC

10 11

AC SUPPLY

P N

12

E

24 / 12 VDC

DC SUPPLY

10 11

22

23

230VAC

12/24VDC

N/A N/A

RTD

VDC

A

B

B

v

T/C

mA

CH:1 INPUT

CH:2 INPUT

CH:2 INPUT

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

5

4 Digit 7 segment dedicated to display the Ch:1 Present value. In the

Programing mode it shows Parameter.

RL-1 LED It indicates the status of Relay-1, When LED is On, Relay is Off and When

LED if Off, Relay is On.

RL-2 LED It indicates the status of Relay-2, When LED is On, Relay is Off and When

LED if Off, Relay is On.

COM LED It indicates the active Communication between devices. When LED is Blink,

the communication is active.

KEYS

MODE KEY Press MODE or Function key to access the programming group or

parameters. press this key to return to the normal view.

NORMAL VIEWS

ENTER KEY ENTER Key allows enter into the Parameter, moving from one parameter

to another or saving a new value of parameter or a status of parameter.

Press to change set points in normal view.

UP KEY UP Key allows increasing the value of a digit selected or changing the

status of parameter in programming mode. Press to change set points in

normal view

PASS KEY PASS Key allows pass the digit of a value from right to left of a selected

parameter in programming mode. In some Parameter it also change or

decrease the value.

3. PROGRAMMING

3.1 Operation Interface

FRONT VIEW

Channel:1 Present

value Display

4 Digit 7 segment dedicated to display the Ch:2 Present value. In the

Programing mode it shows Value of Parameter.

UT-201

M

COM

www.utplindia.in

RL-2

RL-1

8.8.8.8.

201.1

PASS Key

CH:1 PV

Display

UP Key

MODE Key

ENTER Key

Relay-1 LED

COM LED

Relay-2 LED

CH:2 PV

Display

8.8.8.8.

2 0 1.2

Channel:2 Present

value Display

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

6

CPAS

oPAS

0000

nPAS

8888

0000

MODE

pass

SETP

0000

ZrC1

000.0

SPC1

100.0

SP1

030.0

HYS1

000.2

SP2

050.0

HYS2

000.2

SP3

060.0

HYS3

000.2

SP4

080.0

HYS4

000.2

MODE

pass

ZrC2

000.0

SPC2

100.0

COnf

0000

1Np1

rtd1

TSP1

L oN

TSP2

L oN

MODE

pass

DP1

0001

Ded1

no

1Np2

rtd1

TSP3

L oN

TSP4

L oN

DP2

0001

BAUD

9600

PRTy

NoNE

NADD

0001

Ded2

no

WARNING

INJURY

Programming parameter should be accessed only by Personnel who are

technically competent to do so. Local regulations regarding electrical &

safety must be observed.

FAILURE TO COMPLY WITH THESE INSTRUCTION COULD BE RESULT IN SERIOUS INJURY OR DEATH

*

*

*

Default Password will be 0000

Protected Parameter Password will be 1111

NOTE :

These are the whole parameter list. Parameters

can be very as per Type or Requirement by User.

*

To come out from Programming Mode to

Normal mode Press key in any step.

CALA

0032

CZR1

----

CSP1

----

CZR2

----

CSP2

----

LoP1

----

HoP1

----

CAL

0000

MODE

pass

LoP2

----

HoP2

----

CH:2

CH:1

3.2 Mode Access Flow Chart.

8888

8888

Normal Mode

Mode Selection

Configuration Setup

Mode Mode

Change

Password Mode

Calibration

Mode

Password Protected

*Any New Password

*

Press key to enter into the

Programming mode from

Normal mode

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

7

‘Configuration Mode’ will shown by pressing key in the Normal mode..

4.1 Configuration Mode

4. OPERATIONAL MODES

: Selected

YES

: Not

no

DED1

no

CHANNEL:1 DEAD BAND

Operate Relay-1 on two set points Values :

Default Value : no

If set as YES, Only Relay-1 get operated in this

parameter, relay get active on set point 1[SP1]

value and deactivate in set point 2[SP2] value.

Used for Level Control & Fan Operation.

Increase by key, Decrease by key.

Range / Values

Parameter

pass

0000

CONFIGURATION MODE PASSWORD

Password for Config. Mode Parameters

Display

: PT-100 (RTD)

: Linear 0 - 20 mA DC

: Linear 4 - 20 mA DC

T. TC

S. TC

R. TC

J. TC

: ‘T’ Type Thermo-Couple

: ‘S’ Type Thermo-Couple

: ‘R’ Type Thermo-Couple

: ‘K’ Type Thermo-Couple

: ‘J’ Type Thermo-Couple

: Linear 0 - 10 V DC

Scroll the digit by key, Increase by key.

Range : Values between 0000 to 9999

Default Input : RtD1 , It can be change as reqd.

1nP1

rtd1

CHANNEL:1 INPUT TYPE

Selection of the applied Input.

Change the type Up by key, Down by key.

Range : Input Type is as follows:

. TC

4

RTD1

0-20

4-20

-10v

Default Value : 0000

tsp1

L on

ALARM 1 RELAY ACTION

Alarm Relay activation direction.

Values :

Default Value : L on

: No decimal (1234)

0000

: Active in High

H oN

ON

OFF PV

SV

ON

OFF PV

SV

L ON :

: Active in Low

L oN

H ON :

: One decimal (123.4)

0001

: Two decimal (12.34)

0002

: Three decimal(1.234)

0003

SV-Hyst

SV+Hyst

Change the value by key, or by key.

tsp2

L on

ALARM 2 RELAY ACTION

Alarm Relay activation direction same as AL:1

Values :

Default Value : L on

: Active in High

H oN

: Active in Low

L oN

Increase by key, Decrease by key.

dp1

0001

CHANNEL:1 DECIMAL POINT [LINEAR INPUT]

Decimal Point resolution for display value.

Values :

Default Value : 0001

NOTE : Applicable for Analog Linear input only.

Change the value by key, or by key.

: PT-100 (RTD)

: Linear 0 - 20 mA DC

: Linear 4 - 20 mA DC

T. TC

S. TC

R. TC

J. TC

: ‘T’ Type Thermo-Couple

: ‘S’ Type Thermo-Couple

: ‘R’ Type Thermo-Couple

: ‘K’ Type Thermo-Couple

: ‘J’ Type Thermo-Couple

: Linear 0 - 10 V DC

Default Input : J. TC , It can be change as reqd.

1nP2

rtd1

CHANNEL:2 INPUT TYPE

Selection of the applied Input.

Change the type Up by key, Down by key.

Range : Input Type is as follows:

. TC

4

RTD1

0-20

4-20

-10v

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

8

Continue Configuration Mode

WARNING

PERSONAL INJURY :

Configuration should be performed only by personnel who are technically competent to do

so. Local Regulations regarding electrical & safety must be observed.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS INJURY.

: Selected

YES

: Not

no

DED2

no

CHANNEL:2 DEAD BAND

Operate Relay-2 on two set points Values :

Default Value : no

If set as YES, Only Relay-1 get operated in this

parameter, relay get active on set point 1[SP1]

value and deactivate in set point 2[SP2] value.

Used for Level Control & Fan Operation.

Increase by key, Decrease by key.

: No decimal (1234)

0000

: One decimal (123.4)

0001

: Two decimal (12.34)

0002

: Three decimal(1.234)

0003

Increase by key, Decrease by key.

dp2

0001

CHANNEL:2 DECIMAL POINT [LINEAR INPUT]

Decimal Point resolution for display value.

Values :

Default Value : 0001

NOTE : Applicable for Analog Linear input only.

tsp3

tsp4

ALARM 3 & 4 RELAY ACTION

Alarm Relay activation direction same as AL 1&2

Values :

Default Value : L on

: Active in High

H oN

: Active in Low

L oN

Change the value by key, or by key.

&

Range / Values

Parameter

nadd

0001

NODE ADDRESS [COMMUNICATION]

Device Address for Communication

Display

Increase the no. by key, decrease by key.

Range : Values between 0001 to 0127

Default Value : 0001

: Baud Rate 4800

4800

: Baud Rate 9600

9600

: Baud Rate 19200

19.2k

Change value by key, or by key.

baud

9600

BAUD RATE [COMMUNICATION]

Baud Rate for Communication

Values :

Default Value : 9600

NOTE : Applicable if Communication Output.

NOTE : Applicable if Communication Output.

: Even Parity

EvEn

: Odd Parity

Odd

: None Parity

none

Change value by key, or by key.

prty

none

PARITY [COMMUNICATION]

Parity check for Communication

Values :

Default Value : none

NOTE : Applicable if Communication Output.

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

9

‘Setup Mode’ Mode will shown by pressing key, after Conf Mode display.

4.2 Setup Mode

sp3

sp4

Hys3

Hys4

Range / Values

Parameter

pass

0000

SETUP MODE PASSWORD

Password for Setup Mode Parameters

Display

Scroll the digit by key, Increase by key.

Range : Values between 0000 to 9999

Default Value : 0000

ZRC1

000.0

CH:1 ZERO or LOW DISPLAY VALUE [LINEAR I/P]

Display value at Low Input applied.

NOTE : Applicable for Analog Linear input only.

Scroll the digit by key, Increase by key.

Range : Values between 1999 to 9999

Default Value : 000.0

-

Scroll the digit by key, Increase by key.

Range : Values between 1999 to 9999

Default Value : 100.0

-

spC1

100.0

CH:1 SPAN or HIGH DISPLAY VALUE [LINEAR I/P]

Display value at High Input applied.

NOTE : Applicable for Analog Linear input only.

Scroll the digit by key, Increase by key.

Range : Values between 199.9 to 999.9

Default Value : 030.0

-

sp1

030.0

ALARM SET POINT # 1

Activation value for Alarm Relay-1

Scroll the digit by key, Increase by key.

Range : Values between 199.9 to 999.9

Default Value : 000.2

-

Hys1

000.2

HYSTERESIS ALARM # 1

Value Diff. between On and Off of Relay-1

Scroll the digit by key, Increase by key.

Range : Values between 199.9 to 999.9

Default Value : As per User’s set Reqd.

-

ALARM SET POINT # 3 & 4

Activation value for Alarm Relay-3 & 4

Scroll the digit by key, Increase by key.

Range : Values between 199.9 to 999.9

Default Value : 000.2

-

HYSTERESIS ALARM # 3 & 4

Value Diff. between On and Off of Relay-3 & 4

(According to Decimal point)

(According to Decimal point)

(According to Decimal point)

(According to Decimal point)

(According to Decimal point)

(According to Decimal point)

HYS2

sp2

Scroll the digit by key, Increase by key.

Range : Values between 199.9 to 999.9

Default Value : As per User’s set Reqd.

-

ALARM SET POINT & HYSTERESIS # 2

Activation value & Hysteresis for Alarm Relay-2

(According to Decimal point)

&

ZRC2

000.0

CH:2 ZERO or LOW DISPLAY VALUE [LINEAR I/P]

Display value at Low Input applied.

NOTE : Applicable for Analog Linear input only.

Scroll the digit by key, Increase by key.

Range : Values between 1999 to 9999

Default Value : 000.0

-

Scroll the digit by key, Increase by key.

Range : Values between 1999 to 9999

Default Value : 100.0

-

spC2

100.0

CH:2 SPAN or HIGH DISPLAY VALUE [LINEAR I/P]

Display value at High Input applied.

NOTE : Applicable for Analog Linear input only.

(According to Decimal point)

(According to Decimal point)

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

10

‘Calibration Mode’ Mode will shown by pressing key, after Setp Mode display.

4.3 Calibration Mode

0100 ~ 0600

0200 ~ 1000

0200 ~ 1000

0200 ~ 1000

0200 ~ 1000

0200 ~ 1000

7000 ~ 8000

7000 ~ 8000

7000 ~ 8000

7000 ~ 8000

7000 ~ 8000

7000 ~ 8000

INPUT

J - T/C

K - T/C

R - T/C

S - T/C

T - T/C

E - T/C

0 mV

0 mV

0 mV

ZERO VALUE

FEED VALUE COUNT

SPAN VALUE

FEED VALUE COUNT

0 mV

0 mV

0 mV

18 mV

18 mV

42 mV

42 mV

42 mV

18 mV

INPUT ZERO VALUE

FEED VALUE COUNT

SPAN VALUE

FEED VALUE COUNT

0100 ~ 0600

0100 ~ 1000

0100 ~ 1000

0100 ~ 1000

0900 ~ 1500

7000 ~ 8000

7000 ~ 8000

7000 ~ 8000

7000 ~ 8000

2000 ~ 3000

4 ~ 20mA

0 ~ 20mA

1 ~ 5 VDC

10VDC

PT-100

4 mA

0 mA

1 VDC

0 VDC

20 mA

20 mA

5 VDC

10 VDC

CALIBRATION VALUES :

0°C

[100.0Ω]

100°C

[138.51Ω]

Set Reqd. O/p by , & key, press key.

NOTE : After output cal. press key for next mode.

Hop1

Hop2

&

Range / Values

Parameter

pass

0000

CALIBRATION MODE PASSWORD

Password for Calibration Mode Parameters

Display

Scroll the digit by key, Increase by key.

Range : Values between 0000 to 9999

Default Value : 0000

zrC1

----

CALIBRATION ZERO or LOW INPUT CH:1

Calibration Zero / Low at Low / Zero PV Input.

NOTE : After Zero Cal. press key for next Para.

Apply Low signal [as per input] & press key.

Range :

Default Value : ----

According to Input Type

CSP1

----

CALIBRATION SPAN or HIGH INPUT CH:1

Calibration Span / High at Span / High PV Input.

NOTE : After Span Cal. press key for next para.

Apply High signal [as per input] & press key.

Lop1

Lop2

CALIBRATION LOW [RETRANSMISSION] OUTPUT

Calibration desired Low Output for Both Input.

NOTE : After out low cal. press key for next Para.

Set Reqd. O/p by , & key, press key.

Note : After Calibration random value

appeared in display, as per input.

Refer below Table for Cal. values range.

Note : After Calibration random value

appeared in display, as per input.

Refer below Table for Cal. values range.

Range :

Default Value : ----

According to Input Type

Note : After Cali. random value should be

below 1000 appeared in display.

Range :

Default Value : strt -> to start cal.

According to Output Type

CALIBRATION HIGH [RETRANSMISSION] OUTPUT

Calibration desired High Output at PV Display.

Range :

Default Value : strt -> to start cal.

According to Output Type

Note : After Cali. random value should be

below 8000 appeared in display.

CALa

0032

CALIBRATION AMBIENT [THERMO COUPLE INP.]

Ambient adjustment for compensation [T/C Inp.]

NOTE : After Amb. Cal. press key for exit.

Set Ambient Temp by & key,press key. Note : After Calibration random value

appeared in display, as per input.

Range :

Default Value : 0032

As per Ambient Temperature.

zrC2

----

CALIBRATION ZERO or LOW INPUT CH:2

Calibration Zero / Low same as Input-1

NOTE : After Zero Cal. press key for next Para.

Range :

Default Value : ----

According to Input Type

CSP1

----

CALIBRATION SPAN or HIGH INPUT CH:2

Calibration Span / High same as Input-1

NOTE : After Span Cal. press key for next para.

Range :

Default Value : ----

According to Input Type

&

@

+91 7046223333 , 9427301436

www.utplindia.in

www

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

11

‘Change Password Mode’ Mode will shown by pressing key, after CAL Mode display.

Open the Input Connection

Sensor Break or Sensor disconnected.

Sign Description Solution

In case the following error messages appear in the display of controller,

please refer to the Error message table below, or call technical support.

OPEN Check the Input sensor wiring

Replace the sensor.

Check the Input sensor wiring

Check the Input type.

Adjust the Range

Excess of PV over the Span value

Check the Input sensor wiring

Check the Input type.

Adjust the Range

Shortage of PV over the Low value

vndr

Over

All LED’s and

display not light

No power to the controller

Controller circuit failed

Check the power connection

Check the supply voltage.

4.4 Change Password Mode

4.5 Error Message.

Range / Values

Parameter

PAsS

0000

CHANGE PASSWORD MODE PASSWORD

Password for Change Password Mode.

Display

Scroll the digit by key, Increase by key.

Range : Values between 0000 to 9999

Default Value : 0000

opas

0000

OLD EXISTING PASSWORD

Old - Default or Existing Password

Scroll the digit by key, Increase by key.

Range : Values between 0000 to 9999

Default Value : 0000

npas

8888

NEW DESIRED PASSWORD

Set new Required Desired Password

Range : Values between 0000 to 9999

Default Value : As per new required.

(Any value) Scroll the digit by key, Increase by key.

CAUTION

PASSWORD PRECAUTIONS

FAILURE TO COMPLY WITH THESE INSTRUCTION MAY RESULT IN INSTRUMENT DAMAGE

*

*

After Changing old password, all parameter are locked. All Modes are not

accessible without new password.

Changed password should be remembered , it cannot be Reset at site.

5. COMMUNICATION [MODBUS RTU] PROTOCOL

5.1 Introduction

The unit can be connected in MODBUS/RTU communication data link protocol to messaging

structure, widely used to establish master - slave communications between devices. Each

device must have unique No. node address. Before starting any communication, choose a

baud rate compatible to the host device. A Modbus data sent from a master to slave tells the

selected slave what to do and what information to send back. The MODBUS/RTU protocol

works with RS232, RS485 and RS422 standards

5.2 MODBUS Configuration Basic settings

The Basic settings for RS-485 Modbus protocol are as follows :

Band rate

Start bit

Data bit

Stop bit

Parity

9600

1

8

1

none

5.3 Register addresses for MODBUS / RTU Protocol

The addressees for RS-485 Modbus protocol are as follows :

5.4 MODBUS system schematic.

DATA+

The system schematic for RS-485 Modbus protocol are as follows :

DATA-

Ethernet

RS-232

or

RS-485

CONVERTER

D- D+

12

UT-201 Device-1

D- D+

12

D- D+

12

D- D+

12

RS-485 BUS

ADD:1 ADD:2 ADD:3 ADD:N

RS-485 BUS

Upto 128

devices

UT-201 Device-2 UT-201 Device-3 UT-201 Device-128

2 core 1 sq/mm shielded cable

www.utplindia.in

@

www

+91 7046223333 , 9427301436

All content are subject to change without notice

due to continuous improvements.

Doc. Ref. 1410/R04/0819

UNITECH TECHNOCRATS PVT LTD

FACTORY:- 78/1/Z/3-Makarpura G.I.D.C.,

N/R Vadasar Bridge. O/p-Gayatri Temple

VADODARA - 390010. Gujarat, INDIA 12

COMPUTER- SCADA

READ ONLY

SR. NO.

1 PROCESS VALUE CH : 1

PARAMETER ABSOLUTE ADDRESS ACCESS TYPE

40001

READ / WRITE

3 SET POINT-1 [SP1] 40003

READ ONLY

2 PROCESS VALUE CH : 2 40002

READ / WRITE

4 SET POINT-2 [SP2] 40004

READ ONLY

5 DECIMAL POINT : 1 40005

READ ONLY

6 DECIMAL POINT : 2 40006

READ / WRITE

7 SET POINT-3 [SP3] 40007

READ / WRITE

8 SET POINT-4 [SP4] 40008

UT-201 UNIVERSAL PROCESS INDICATOR & CONTROLLER

Table of contents

Other Unitech Controllers manuals

Popular Controllers manuals by other brands

Emerson

Emerson AVENTICS 651 Series Installation and maintenance instructions

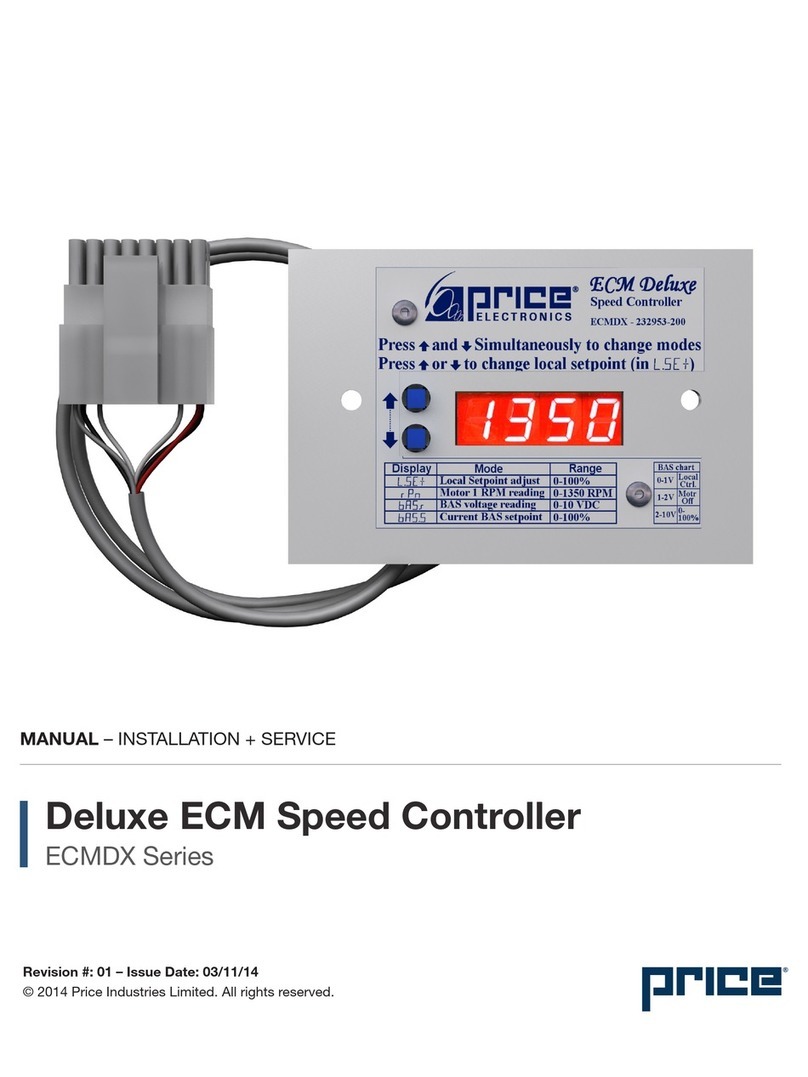

Price

Price ECMDX Series Installation and service manual

GSI Group

GSI Group PNEG-1405 installation manual

Sundstrom

Sundstrom SR 500 Instructions for use

Gewiss

Gewiss GW96 752 Instructions for installation manual

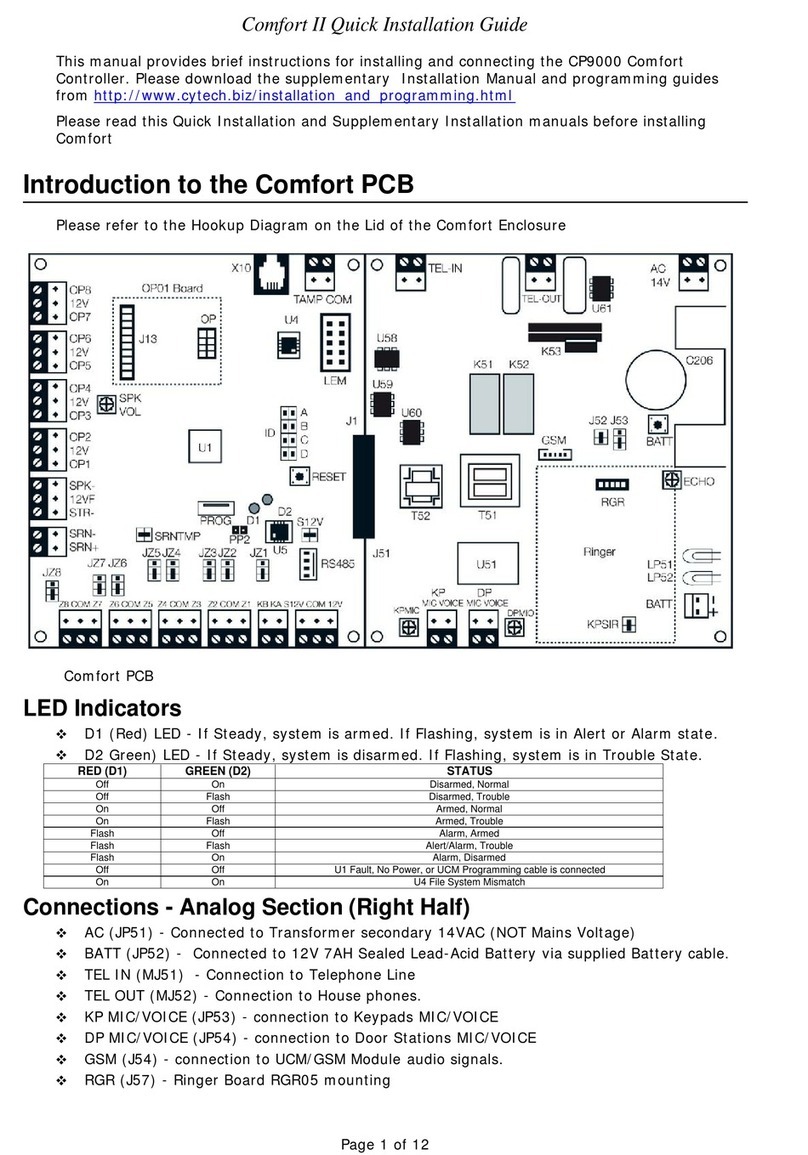

Cytech

Cytech CP9000 Comfort II Quick installation guide

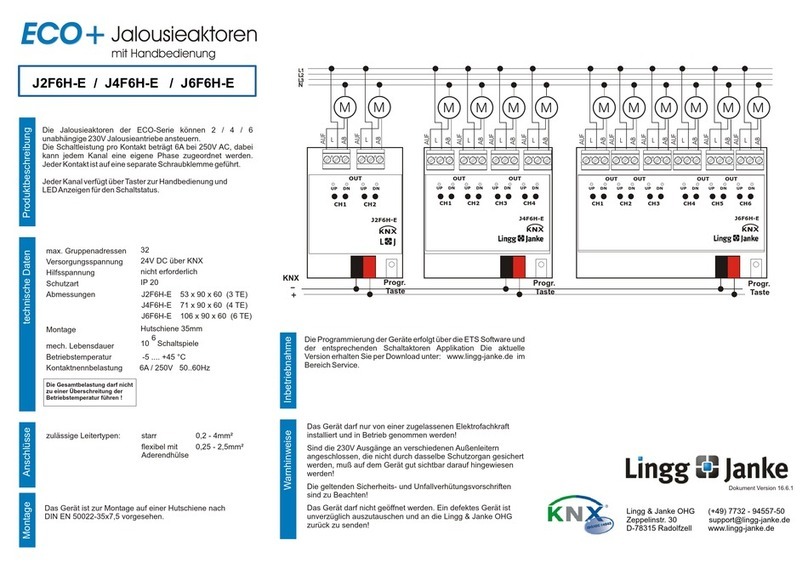

Lingg & Janke

Lingg & Janke ECO+ J2F6H-E manual

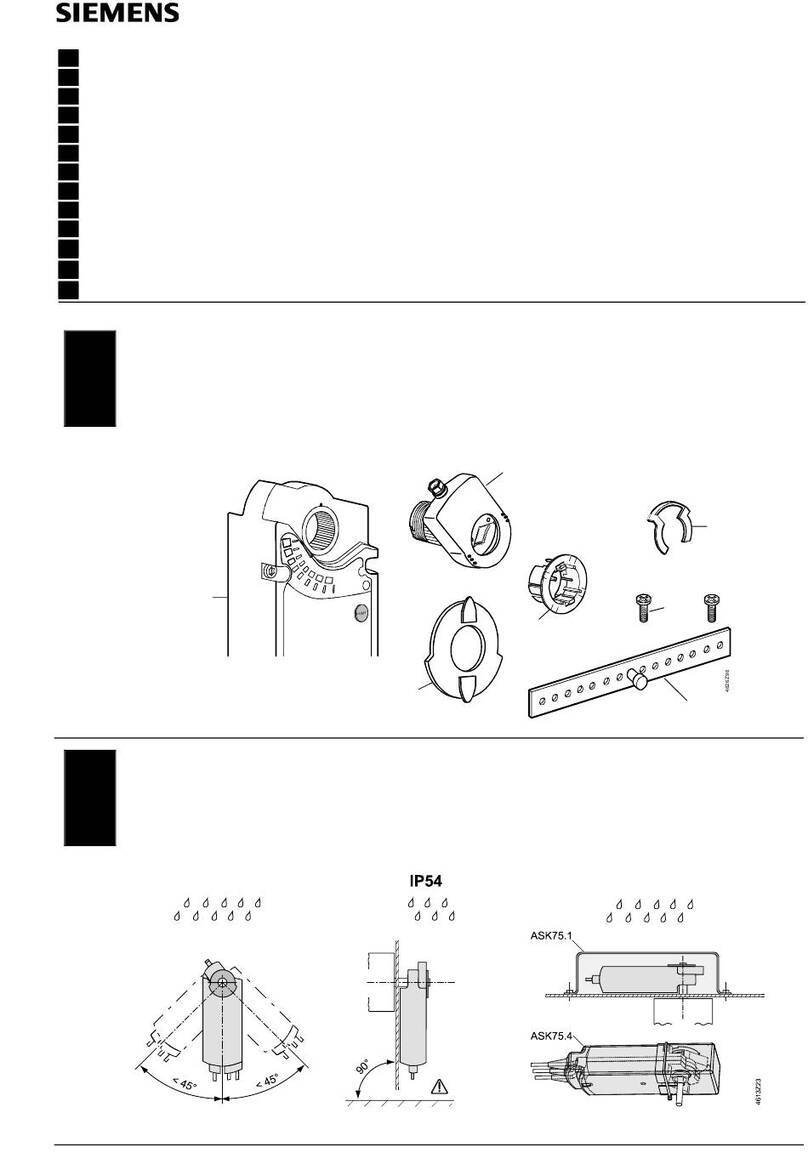

Siemens

Siemens GBB 1E Series Mounting instructions

LINK-MI

LINK-MI LM-TV25 user manual

MidNite Solar

MidNite Solar Classic 150 owner's manual

Mateksys

Mateksys F765-WSE quick start guide

Precision Digital Corporation

Precision Digital Corporation ConsoliDator+ instruction manual