Optidrive VTC –User Guide

www.invertek.co.uk 3

1. INTRODUCTION ................................................................................................................................. 4

1.1. Important safety information .......................................................................................................4

2. GENERAL INFORMATION AND RATINGS ............................................................................................. 5

2.1. Drive model numbers....................................................................................................................5

3. MECHANICAL INSTALLATION ............................................................................................................. 6

3.1. Mechanical dimensions and mounting .........................................................................................6

3.2. Before Installation.........................................................................................................................7

3.3. General Installation.......................................................................................................................7

3.4. Enclosure mounting ......................................................................................................................8

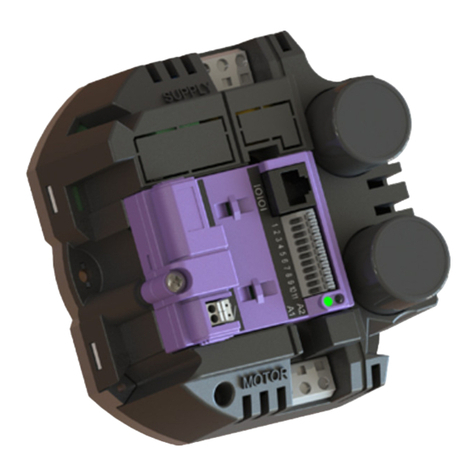

4. ELECTRICAL INSTALLATION ................................................................................................................ 9

4.1. Grounding the Drive......................................................................................................................9

4.2. Wiring Precautions........................................................................................................................9

4.3. Incoming Power Connection .........................................................................................................9

4.4. Connection Diagram ...................................................................................................................10

4.5. Motor Connection and Cables ....................................................................................................10

4.6. Motor Terminal Box Connections ...............................................................................................10

4.7. Dynamic Brake Resistor Connections..........................................................................................10

4.8. Control terminal connections .....................................................................................................11

5. OPERATION ......................................................................................................................................12

5.1. Managing the keypad..................................................................................................................12

5.2. Changing Parameters ..................................................................................................................12

5.3. Advanced Keypad Operation Short Cuts.....................................................................................13

5.4. Reset All Parameters to Factory Default Settings .......................................................................13

5.5. Terminal Control .........................................................................................................................14

5.6. Keypad Control............................................................................................................................14

5.7. Motor Autotuning.......................................................................................................................15

5.8. Operation of Three Phase drives on Single Phase Supplies ........................................................15

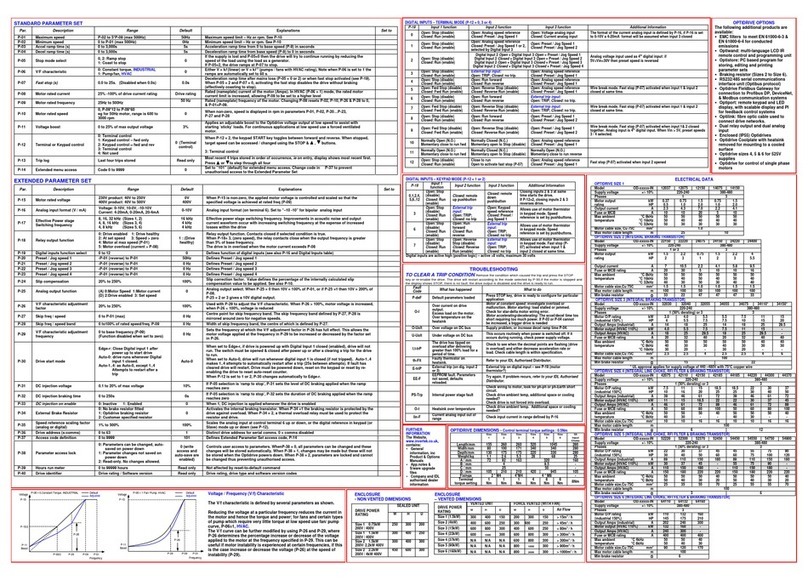

6. PARAMETERS ...................................................................................................................................16

6.1. Parameter Group 1 –Basic Parameters......................................................................................16

6.2. Parameter Group 2 - Extended parameters................................................................................17

6.3. Parameter Group 3 –PID Control ...............................................................................................20

6.4. Parameter Group 4 –High Performance Motor Control ............................................................20

6.5. Parameter Group 0 –Monitoring Parameters (Read Only) ........................................................21

6.6. Fire Mode....................................................................................................................................21

7. ANALOG AND DIGITAL INPUT CONFIGURATIONS...............................................................................22

7.1. Terminal mode (P1-12 =0) ..........................................................................................................22

7.2. Keypad mode (P1-12 = 1 or 2).....................................................................................................23

7.3. User PI control mode (P1-12 = 3)................................................................................................24

7.4. Modbus Control Mode (P1-12 = 4) .............................................................................................24

8. TROUBLESHOOTING..........................................................................................................................25

8.1. Fault messages............................................................................................................................25

9. TECHNICAL DATA..............................................................................................................................26

9.1. Environmental.............................................................................................................................26

9.2. Rating tables ...............................................................................................................................26

9.3. Maximum supply ratings for UL compliance:..............................................................................28

10. MODBUS COMMUNICATIONS...........................................................................................................29

10.1. Introduction ................................................................................................................................29

10.2. Modbus RTU Specification ..........................................................................................................29

10.3. RJ11 Connector Configuration ....................................................................................................29

10.4. Modbus Telegram Structure .......................................................................................................29

10.5. Modbus Register Map.................................................................................................................30

11. PARAMETER SETTING RECORD..........................................................................................................31