AB-6580

∗

Azbil Corporation’s Infilex series controllers: Infilex is named for “Infinity” and “Flexible.”

1

Specifications/Instructions

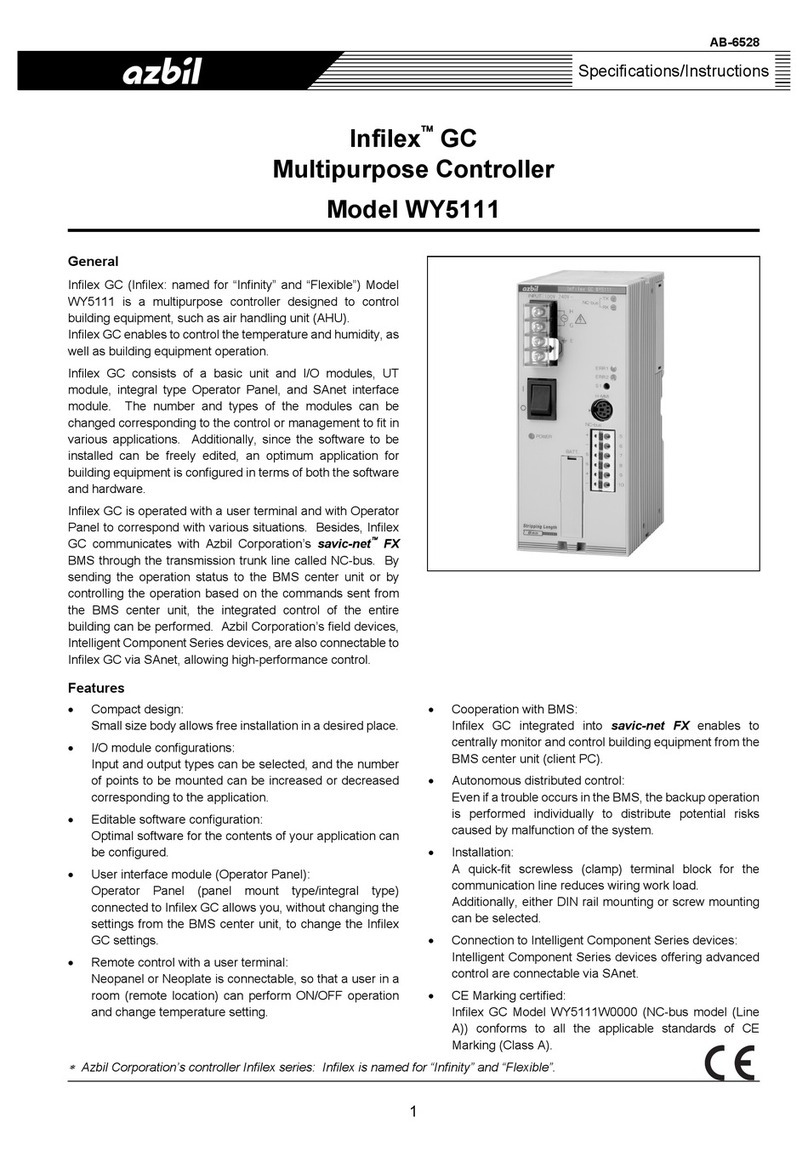

Infilex™GC

Multipurpose Controller

Model WY5311

General

Infilex GC (Infilex: named for “Infinity” and “Flexible”) Model

WY5311 is a multipurpose controller designed to control

building equipment, such as air handling unit (AHU). Infilex

GC enables to control the temperature and humidity, as well

as building equipment operation.

Infilex GC can be operated with a user terminal and with

Operator Panel. Besides, Infilex GC can communicate with

BMS (building management system) Azbil Corporation’s

savic-net™FX via LonTalk®protocol. By sending the

operation status to the main control unit (monitoring

computer) and by controlling the operation based on the

commands sent from the main control unit, the integrated

control of the entire building can be executed.

Infilex GC consists of a basic unit and connectable I/O

modules (and a user interface module). The number and

types of the modules can be flexibly changed corresponding

to the control or management to fit in various applications.

Additionally, since the software to be installed can be freely

edited, an optimum application for building equipment can be

configured in terms of both the software and hardware.

Features

•Compact design:

Small size body allows free installation in a desired

place.

•Various input/output (I/O) configurations:

Input and output types can be selected, and the number

of points to be mounted can be increased or decreased

corresponding to the application.

•Editable software configurations:

Optimal software for the contents of the application can

be configured.

•User interface module (Operator Panel):

Operator Panel (panel mount type/integral type)

connected to Infilex GC allows you, without changing the

settings from the BMS center unit, to change the Infilex

GC settings.

•Remote control with a user terminal:

Neopanel™or Neoplate is connectable, so that a user at

a remote location can perform ON/OFF operation and

change temperature setting.

•Autonomous distributed control:

Even if a trouble occurs in the BMS, the backup

operation is performed individually to distribute potential

risks caused by malfunction of the system.

•Installation:

A quick-fit screwless (clamp) terminal block is used for

the communication terminal block of the I/O module,

ensuring the labor saving of the wiring work.

Additionally, either DIN rail mounting or screw mounting

can be selected.

•L

ONMARK®certified product:

Infilex GC is LONMARK®certified and thus interoperable

integrated in the LONWORKS®system.

•CE Marking certified product:

Infilex GC conforms to all the applicable standards of CE

Marking (Class A).