7

United Industries, Inc.

P.O. Box 58

Sterling, KS 67579

800-835-3272 • 620-278-3160

Fax 800-500-3115 • 620-278-3115

www.towerflo.com

Data presented here is the best available at the

time of publicaton. United Industries and/or its

representatives assume no liability for its use.

Form TFW-PSP-2/2:2/17

Project Specications

Series

TFW

COMPONENT SPECIFICATION

CONTROLS ___ Standard Three phase or single phase, Automatic backwash control panel, UL®and cUL®Labeled, in

a NEMA 4X fiberglass enclosure including: motor starter with thermal overload and short circuit

protection; fuseless branch and control circuit protection; transformer to convert primary supply to

24 and 120 VAC control power; through-the-door disconnect; programmable relay with program of

operation, 7-year battery backup and external memory card backup; HOA switch for pump motor;

differential pressure switch (external to the enclosure) for primary backwash initiation; manual

backwash initiation pushbutton; backwash counter; and contacts for ∆P repeat closure shut-off and

alarm, common alarm (motor trip indication), remote indication of backwash operation, remote

backwash initiation, and conductivity interface. Program features 30-second time delay in ∆P

switch circuit and 100 hour “re-setting” timer (∆P switch closure or manual initiation resets timer)

for backup backwash initiation.

___ Option: Backwash lockout between/among ____ units; to prevent simultaneous backwash of multiple

filter units; 0-60 minute adjustable lockout time delay program; field connection between/

among control panels by others.

___ Option: Contacts for connection to BMS, additional specifications required from owner.

___ local (lights) and remote (contacts) indication of filter or backwash operating mode.

___ other (be specific) _____________________________________________________.

___ Option: Manual backwash; ___ single-phase; ___ three-phase.

MEDIA ___ Standard: Quartzite or silica in nature, hard, not smooth, uniformity coefficient of 1.7, relative size of .45

to .55 mm, containing no more than 5% flat particles or more than 1% clay, loam dust, or other

foreign material. Media weighs 100 lbs per cubic foot.

COMMON ADDITIONAL EQUIPMENT:

NOZZLES ___ Sweeper-Eductor Nozzle, 1/4" MPT, ABS plastic, quantity of _____.

HOLDERS ___ Clip-On Nozzle Holder, quantity of _____; for ___ 1-1/4"; ___ 1-1/2"; or ___ 2" PVC pipe.

SURGE TANK ___ Polyethylene tank for backwash surge capture and gravity release to closest drain:______ gallon capacity,

____" diameter x ____" high, with a ___" diameter lid in top head and a 2" FPT drain bulkhead fitting.

___ Bulkhead fitting, additional, for inlet from filter ___ 2", ___3", or ___ 4", for field installed by others;

___ Manual ball valve, 2", 2-way, ___ Sch 40 PVC, ___ Sch 80 PVC, ___ brass, for field installation by others

on drain piping from tank for isolation and/or throttling.

LIQUID LEVEL ___ Liquid level control assembly for backwash surge tank to interrupt filter pump if/when surge tank nears

capacity. Includes: Gems Series 16M liquid level controller mounted in separate NEMA 3R enclosure requir-

ing separate 120 V power supply factory mounted on filter’s control panel bracket (unless otherwise speci-

ficed); sensor; 3 trimmable probes (L, H, and Ground); field wiring from sensor to LLC enclosure by others.

Also includes additional contacts for remote pump on/off in filter control panel.

___ Liquid level control column assembly; 2” Sch 80 piping assembly mounted on side of poly tank to

isolate liquid level probes from turbulance in poly tank.

SOLENOID VALVE ___ Solenoid valve for backwash siphon break, _____", bronze, with 24 VAC solenoid.

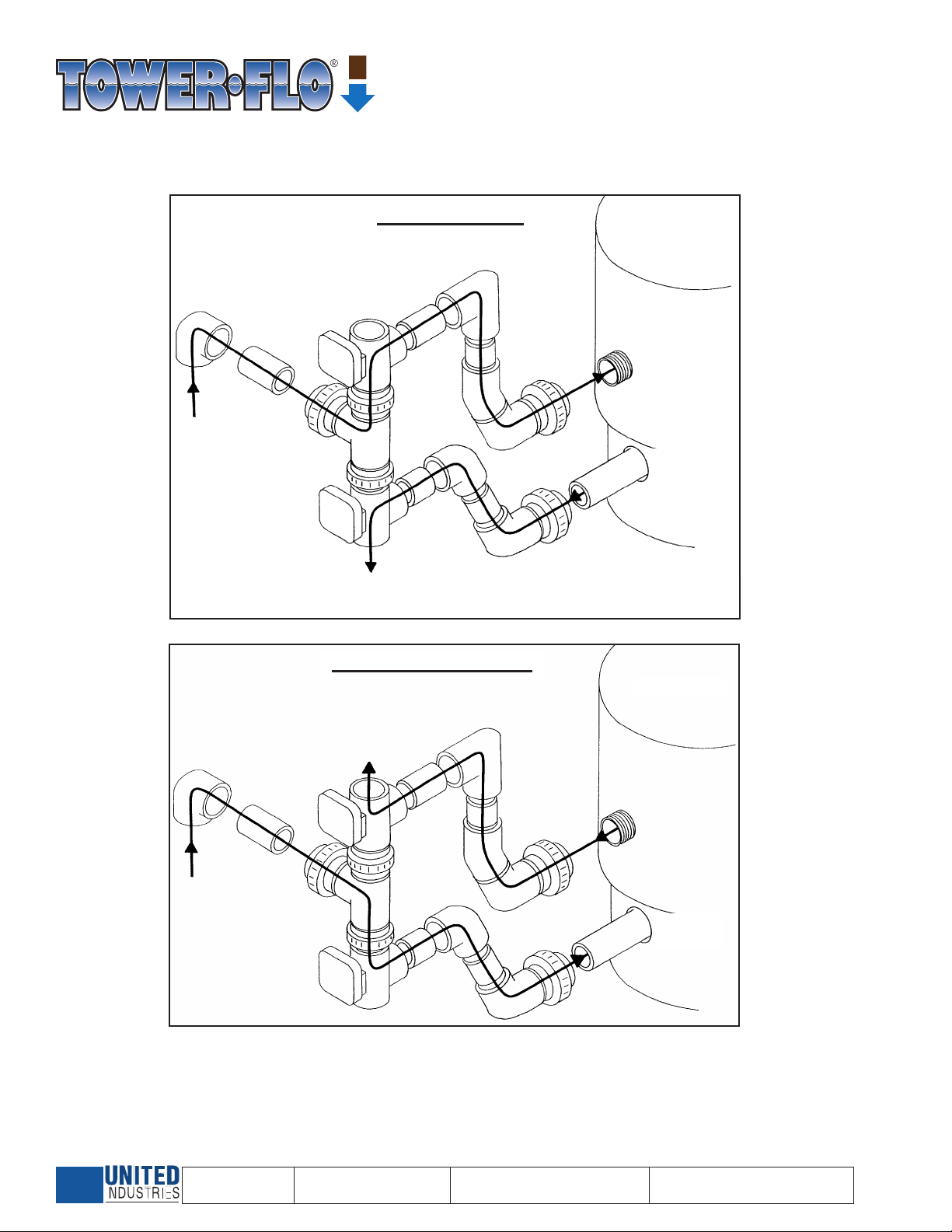

NOTE: Backwash flow rate, irrespective of water source, must be no less than 75% and no greater than 100% of the vessel's

designed maximum gpm. Backwash duration is factory preset at 3 minutes and is field adjustable.