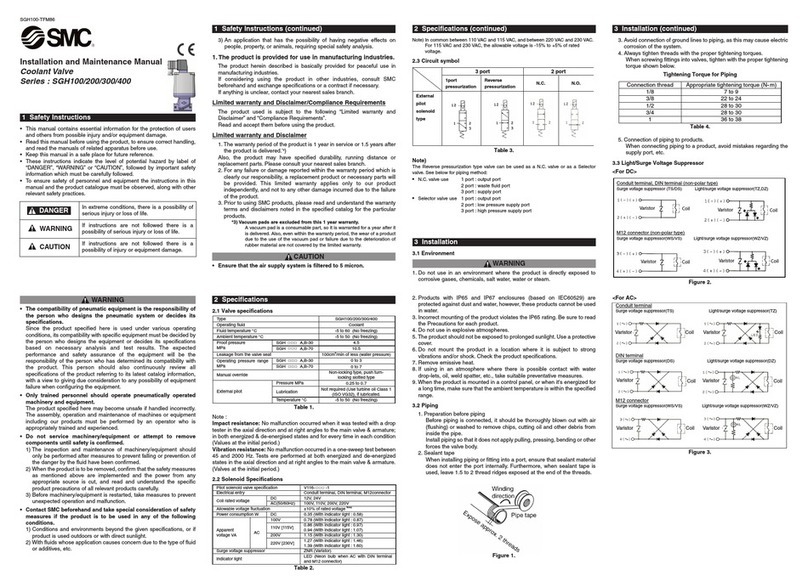

Installation and Maintenance Manual

Series SYJ300/500/700 Solenoid Valve (3 Port)

This manual should be read in conjunction with the current valve catallogue

For future reference, please keep this manual in a safe place

Safety Instructions

These safety instructions are intended to prevent a hazardous situa-

tion and/or equipment damage.These instructions indicate the level

of potential hazard by label of “Caution”, “Warning” or “Danger”.

To ensure safety, be sure to observe ISO4414 (Note1), JIS B 8370 (Note2)

and other safety practices.

Note 1: ISO 4414: Pneumatic fluid power – Recommendations for the

application of equipment to transmission and control systems.

Note 2: JIS B 8370: Pneumatic system axiom.

CAUTION : Operator error could result in injury or

equipment damage.

WARNING: Operator error could result in serious

injury or loss of life.

DANGER : In extreme conditions, there is a

possible result of serious injury or loss of life.

WARNING

1. The compatibility of pneumatic equipment is the respon-

sibility of the person who designs the pneumatic system

or decides its specifications.

Since the products specified here are used in various operating

conditions, their compatibility for the specific pneumatic system

must be based on specifications or after analysis and/or tests to

meet your specific requirements.

2. Only trained personnel should operate pneumatically

operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar

with it. Assembly, handling or repair of pneumatic systems should

be performed by trained and experienced operators.

3. Do not service machinery/equipment or attempt to

remove component until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should

only be performed after confirmation of safe locked-out

control positions.

2) When equipment is to be removed, confirm the safety process

as mentioned above.Switch off air and electrical supplies and

exhaust all residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc.

(Bleed air into the system gradually to create back-pressure,

i.e. incorporate a soft-start valve).

4. Contact SMC if the product is to be used in any of the

following conditions:

1) Conditions and environments beyond the given specifica-

tions, or if product is used outdoors.

2) Installations in conjunction with atomic energy, railway, air

navigation, vehicles, medical equipment, food and beverage,

recreation equipment, emergency stop circuits, press

applications, or safety equipment.

3) An application which has the possibility of having negative

effects on people, property, or animals, requiring special

safety analysis.

CAUTION

Ensure that the air supply system is filtered to 5 micron.

SYJ300/500/700 Series Common Solenoid Specifications

Solenoid specifications

Electrical entry Grommet (G) · (H), L type plug connector (L),

M type plug connector (M)

Coil rated voltage V DC 24, 12, 6, 5, 3

Allowable voltage ±10% rated voltage

Power consumption W Note) DC 0.5 (with light: 0.55)

Surge voltage suppressor Diode

Indicator light LED

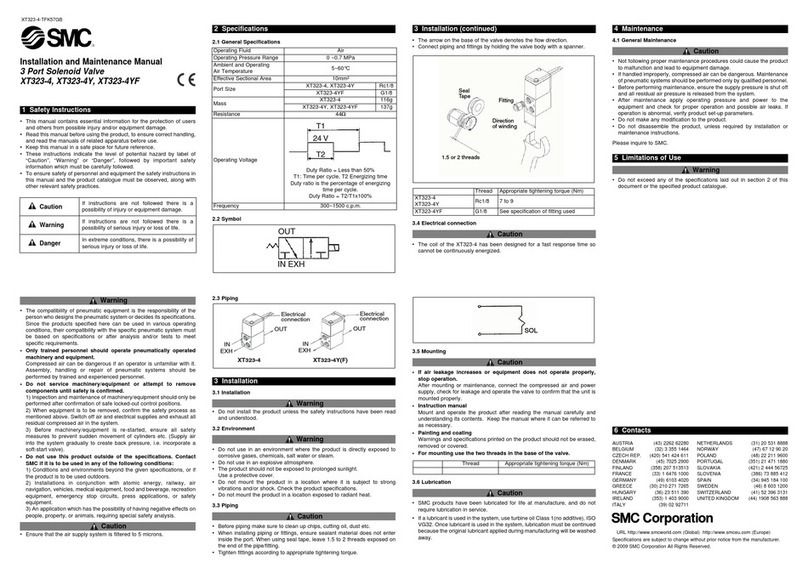

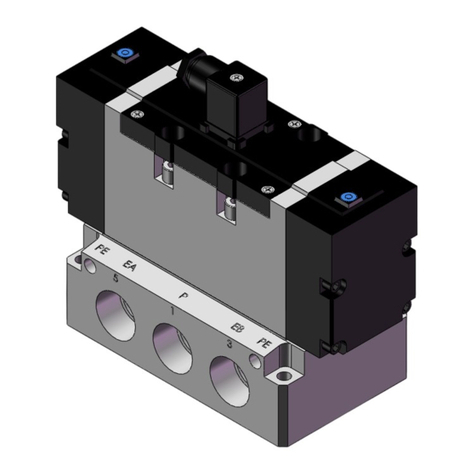

SYJ300 Series (Fig 1a, b)

Model

Valve model Type Port Effective Weight g

of size mm2(Cv) Grommet

L type plug connector,

actuation

M type plug connector

Body ported type SYJ312 N.C. M3x0.5 0.9 (0.05) 29 31

SYJ322 N.O.

Base mounted type SYJ314 N.C. M5x0.8 1.8 (0.1) 50 52

(with sub-plate) SYJ324 N.O.

(without sub-plate 29) (without sub-plate 31)

Valve specifications

Fluid Air

Operating pressure range Internal pilot 0.15~0.7 (1.5~7.1)

MPa (kgf/cm2)

Ambient and fluid temperature °C Max.50

Response time ms (at 0.5MPa [5.1 kgf/cm2]) Note 1 15 or less

Max. operating frequency Hz 10

Manual override Non-locking push type, push-locking slotted type

Pilot exhaust

Individual pilot exhaust type. Common exhaust (pilot and main valve) type

Lubrication Not required

Mounting position Free

Impact/vibration resistance m/s2150/30 Note 1)

Protection structure IP40

Note: Impact resistance: There should be no malfunction of the valve after testing, using a drop impact tester, along the valve axis and at right

angles to the valve and armature. Carry out each test with the valve energised and de-energised.

Vibration resistance:There should be no malfunction of the valve after testing, using an 8,3 to 2000Hz sweep, along the axis and at right

angles to the valve and armature. Carry out each test with the valve energised and de-energised.

SYJ700 Series (Fig 3a, b)

Model

Valve model Type Port Effective Weight g

of size mm2(Cv) Grommet

L type plug connector,

actuation

M type plug connector

Body ported type SYJ712 N.C. Rc (PT) 1/80.9 (0.05) 72 74

SYJ722 N.O.

Base mounted type SYJ714 N.C. Rc (PT) 1/80.9 (0.05) 132 134

(with sub-plate) SYJ724 N.O. Rc (PT) 1/4

(without sub-plate 72) (without sub-plate 74)

Valve Specifications

Fluid Air

Operating pressure range Internal pilot 0.15~0.7 (1.5~7.1)

MPa (kgf/cm2)

Ambient and fluid temperature °C Max.50

Response time ms (at 0.5MPa [5.1 kgf/cm2]) Note 1 30 or less

Max. operating frequency Hz 5

Manual override Non-locking push type, push-locking slotted type

Pilot exhaust

Individual pilot exhaust type. Common exhaust (pilot and main valve) type

Lubrication Not required

Mounting position Free

Impact/vibration resistance m/s2150/30 Note 1)

Protection structure IP40

Note: Impact resistance: There should be no malfunction of the valve after testing, using a drop impact tester, along the valve axis and at right

angles to the valve and armature. Carry out each test with the valve energised and de-energised.

Vibration resistance:There should be no malfunction of the valve after testing, using an 8,3 to 2000Hz sweep, along the axis and at right

angles to the valve and armature. Carry out each test with the valve energised and de-energised.

036a/eng

Installation

CAUTION

Ensure all air and power supplies are ISOLATED before commencing

installation.

WARNING

DO NOT INSTALL THESE VALVES IN EXPLOSIVE ATMOSPHERES.

If these valves are exposed to water or oil droplets, ensure that the

valves are protected.

If it is intended to energise a valve for an extended period please

consult SMC.

SYJ300 Series (Fig 1a)

Fig 1a

Fig 2b

Fig 1b Fig 2a

Internal pilot External pilot

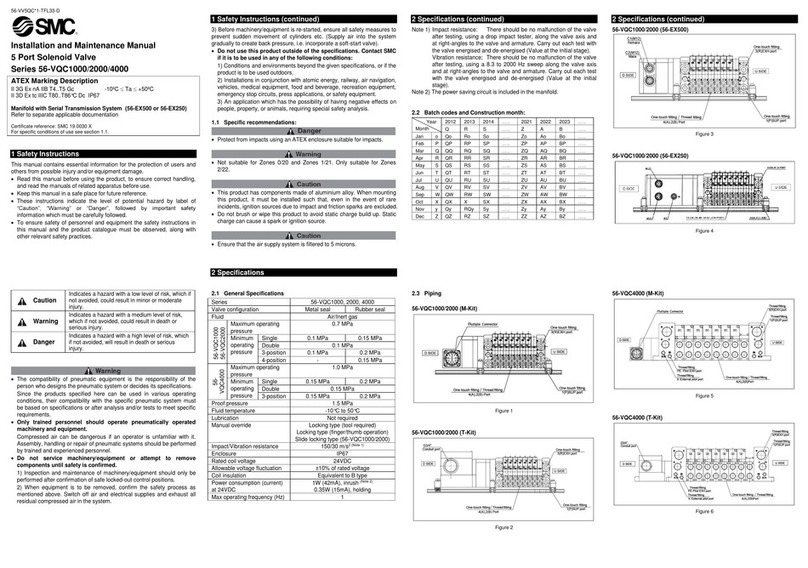

Manifold Specifications

Type For internal pilot Type 20 Type 41,S41 Type 42,S42

For external pilot Type 20R - Type 42R,S42R

Manifold type Single base type /B mount

P(SUP) · R(EXH) type Common SUP · Common EXH

Valve stations 2-20 stations

A port specifications Location Valve Base

Direction Top Side

Port size

P,R port M5x0.8 M5x0.8 Rc(PT) 1/8

Rc(PT) 1/8M5x0.8

A port M3x0.5 M3x0.5 C4 (ø4 one-touch fitting)

X portNote 1) M5x0.8 - M5-0.8

Note 2 Body ported type 0.9 (0.05) -

Valve effective area SYJ 2/SYJ3 2R

mm2(Cv) Base mounted type - 1.5 (0.08)

SYJ3 4/SYJ3 4R

Note 1: Only for external pilot

Note 2: Value when used on a manifold Manifold Specifications

Type For internal pilot Type 20 Type 40 Type 41

For external pilot Type 21R Type 40R Type 41R

Manifold type Single base type /B mount

P(SUP) · R(EXH) type Common SUP · Common EXH

Valve stations 2-20 stations

A port specifications Location Valve Base

Direction Top Bottom Side

Port size

P,R port Rc(PT) 1/8Rc(PT) 1/8Rc(PT) 1/8

M5x0.8, Rc(PT) 1/8

A port M5x0.8 M5x0.8 C4 (ø4 one-touch fitting)

Rc(PT) 1/8C6 (ø6 one-touch fitting)

X portNote 1) M5x0.8 M5x0.8 M5x0.8

Body ported type 3.4 (0.19) -

Note 2 SYJ5 2/SYJ5 2R

Valve effective area Base mounted type - M5: 3.8 (0.21) M5: 3.3 (0.18)

mm2(Cv) SYJ5 4/SYJ5 4R 1/8 : 4.7 (0.26) 1/8 : 4.8 (0.27)

C4, C6 : 3.8 (0.21)

Note 1: Only for external pilot

Note 2: Value when used on a manifold

SYJ500 Series (Fig 2a, b)

Model

Valve model Type Port Effective Weight g Note)

of size mm2(Cv) Grommet

L type plug connector,

actuation

M type plug connector

Body ported type SYJ512 N.C. M5x0.8 3.6 (0.2) 43 45

SYJ522 N.O.

Base mounted type SYJ514 N.C. Rc(PT)1/84.5 (0.25) 57 59

(with sub-plate) SYJ524 N.O.

(without sub-plate 43) (without sub-plate 45)

Valve Specifications

Fluid Air

Operating pressure range Internal pilot 0.15~0.7 (1.5~7.1)

MPa (kgf/cm2)

Ambient and fluid temperature °C Max.50

Response time ms (at 0.5MPa [5.1 kgf/cm2]) 25 or less

Max. operating frequency Hz 5

Manual override Non-locking push type, push turn-locking slotted type

Pilot exhaust

Individual pilot exhaust type. Common exhaust (pilot and main valve) type

Lubrication Not required

Mounting position Free

Impact/vibration resistance m/s2150/30 Note 1)

Protection structure IP40

Note: Impact resistance: There should be no malfunction of the valve after testing, using a drop impact tester, along the valve axis and at right

angles to the valve and armature. Carry out each test with the valve energised and de-energised.

Vibration resistance:There should be no malfunction of the valve after testing, using an 8,3 to 2000Hz sweep, along the axis and at right

angles to the valve and armature. Carry out each test with the valve energised and de-energised.

Internal pilot

External pilot

Fig 3a

Fig 3b

Internal pilot

External pilot

External pilot type

SYJ300R

External pilot type

SYJ500R

Specifications

Applicable model Base mounted type

(SYJ314R, SYJ324R)

Operating pressure Main pressure

-100kPa~0.7{10 torr~7.1}

range MPa {kgf/cm2} External pilot pressure 0.15~0.7{1.5~7.1}

P, R port

M5x0.8

A port

M5x0.8

X port (external pilot)

M5x0.8

Note: Externally piloted body ported valves (SYJ3k2R) can

only be used on the manifold.

Specifications

Applicable model Base mounted type

(SYJ514R, SYJ524R)

Operating pressure Main pressure

-100kPa~0.7{10 torr~7.1}

range MPa {kgf/cm2} External pilot pressure 0.15~0.7{1.5~7.1}

Note: Externally piloted body ported valves (SYJ5k2R) can

only be used on the manifold.

For body ported models with the external pilot option

contact SMC.

P, R port

Rc(PT)1/8

A port

Rc(PT)1/8

X port

(external pilot)

M5x0.8

X port (external pilot)

M5x0.8

P, R port

Rc(PT)1/8,1/4

A port

Rc(PT)1/8,1/4

External pilot type

SYJ700R

Note: Externally piloted body ported valves (SYJ7k2R) can

only be used on the manifold.

For body ported models with the external pilot option contact

SMC.

Specifications

Applicable model Base mounted type

(SYJ714R, SYJ724R)

Operating pressure Main pressure

-100kPa~0.7{10 torr~7.1}

range MPa {kgf/cm2} External pilot pressure 0.15~0.7{1.5~7.1}