Table of contents

1Basic - Information.....................................................................................................................3

1.1 History .......................................................................................................................................... 3

1.2 Other products ............................................................................................................................. 3

1.3 Project planning instructions (MANUAL) ..................................................................................... 3

1.4 Validity.......................................................................................................................................... 4

1.5 Designations and symbols used ................................................................................................... 4

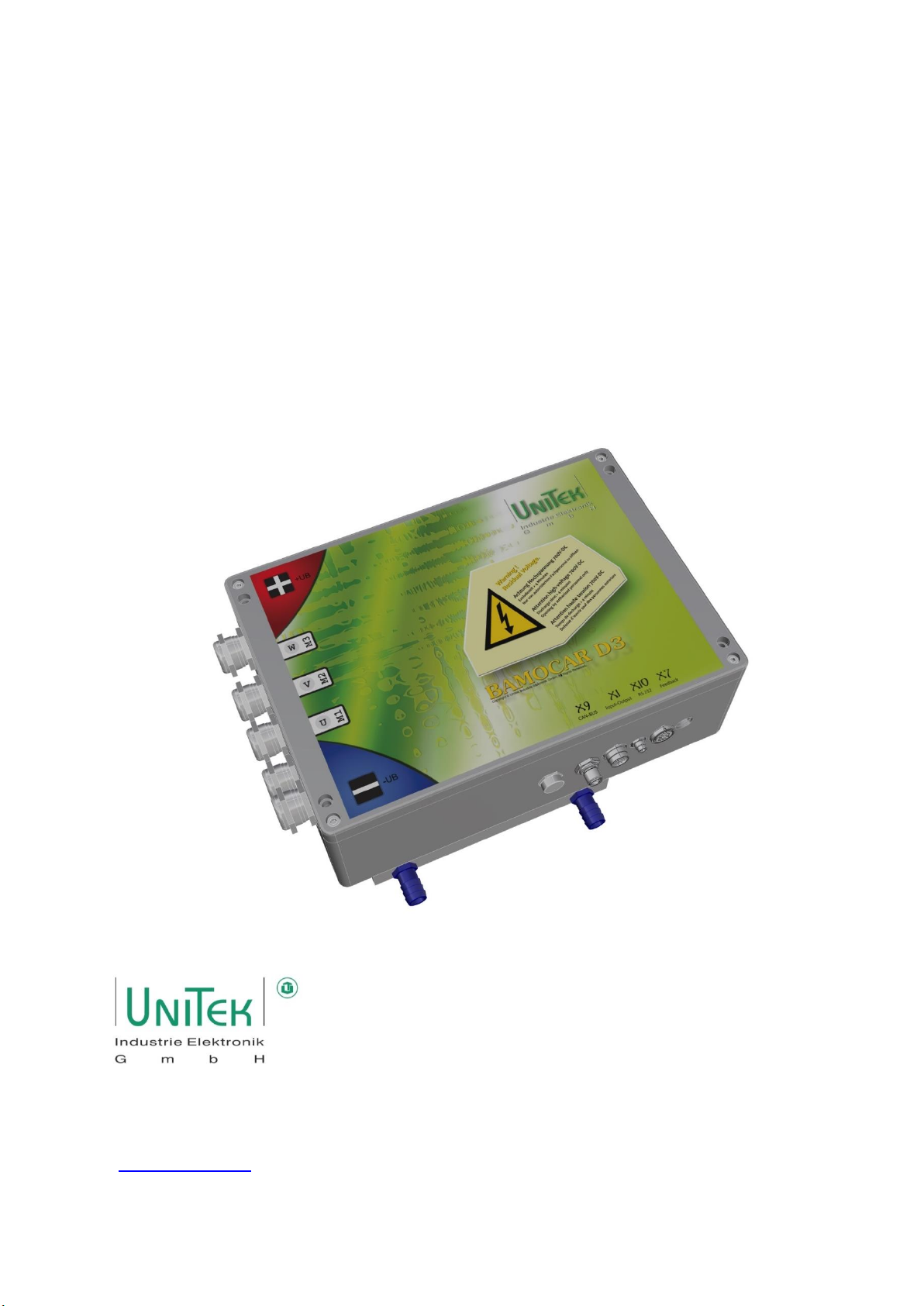

1.6 General product information ....................................................................................................... 5

1.7 Application/use/design/property................................................................................................. 6

1.8 Safety regulations......................................................................................................................... 8

1.9 Commissioning ........................................................................................................................... 10

1.10 Details of the safety instructions................................................................................................ 11

1.11 Intended use............................................................................................................................... 12

1.12 Regulations and guidelines......................................................................................................... 13

1.13 Risks............................................................................................................................................ 14

1.14 Technical data ............................................................................................................................ 15

2Mechanical installation ............................................................................................................ 18

2.1 Important notes ......................................................................................................................... 18

2.2 Dimension drawings BAMOCAR-PG-D3-400/400, 700/250, 700/400 ....................................... 19

2.3 Mounting on mounting rails....................................................................................................... 21

2.4 Mounting on mounting surface.................................................................................................. 21

3Electrical installations .............................................................................................................. 22

3.1 Important notes ......................................................................................................................... 22

3.2 Block diagrams ........................................................................................................................... 23

3.3 Connection overview.................................................................................................................. 25

3.4 EMC ............................................................................................................................................ 26

3.5 Connector overview ................................................................................................................... 28

3.6 Auxiliary voltage connection...................................................................................................... 30

3.7 Power connections..................................................................................................................... 31

3.8 Battery connection..................................................................................................................... 32

3.9 Motor power connection ........................................................................................................... 33

4Control connections................................................................................................................. 34

4.1 Digital inputs............................................................................................................................... 34

4.2 Safety input RFE (rotating field - enable) / stop category 0....................................................... 35

4.3 Digital outputs (0pen emitter).................................................................................................... 36

4.4 Signalling contact Ready for operation (solid state relay) / Ready BTB / RDY........................... 37

4.5 Analogue inputs ±10 V................................................................................................................ 38

4.6 Analogue output - not available................................................................................................. 38