2

PREFACE

SPECIFICATIONS

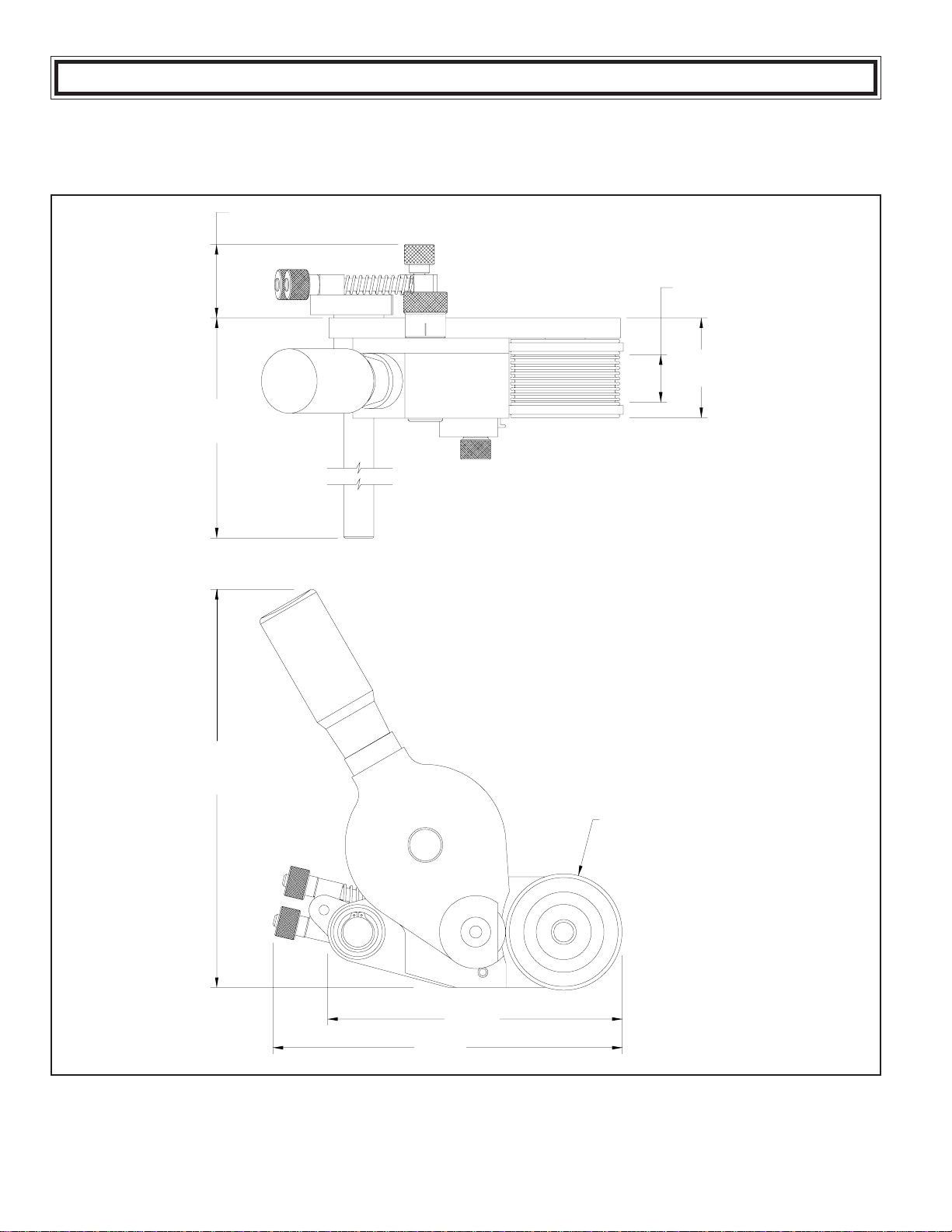

MC-10NI Top Mount Series

MC-10 Side Mount Series

Indexing & Non-Indexing Models

Mounting Configuration

Printing Dies

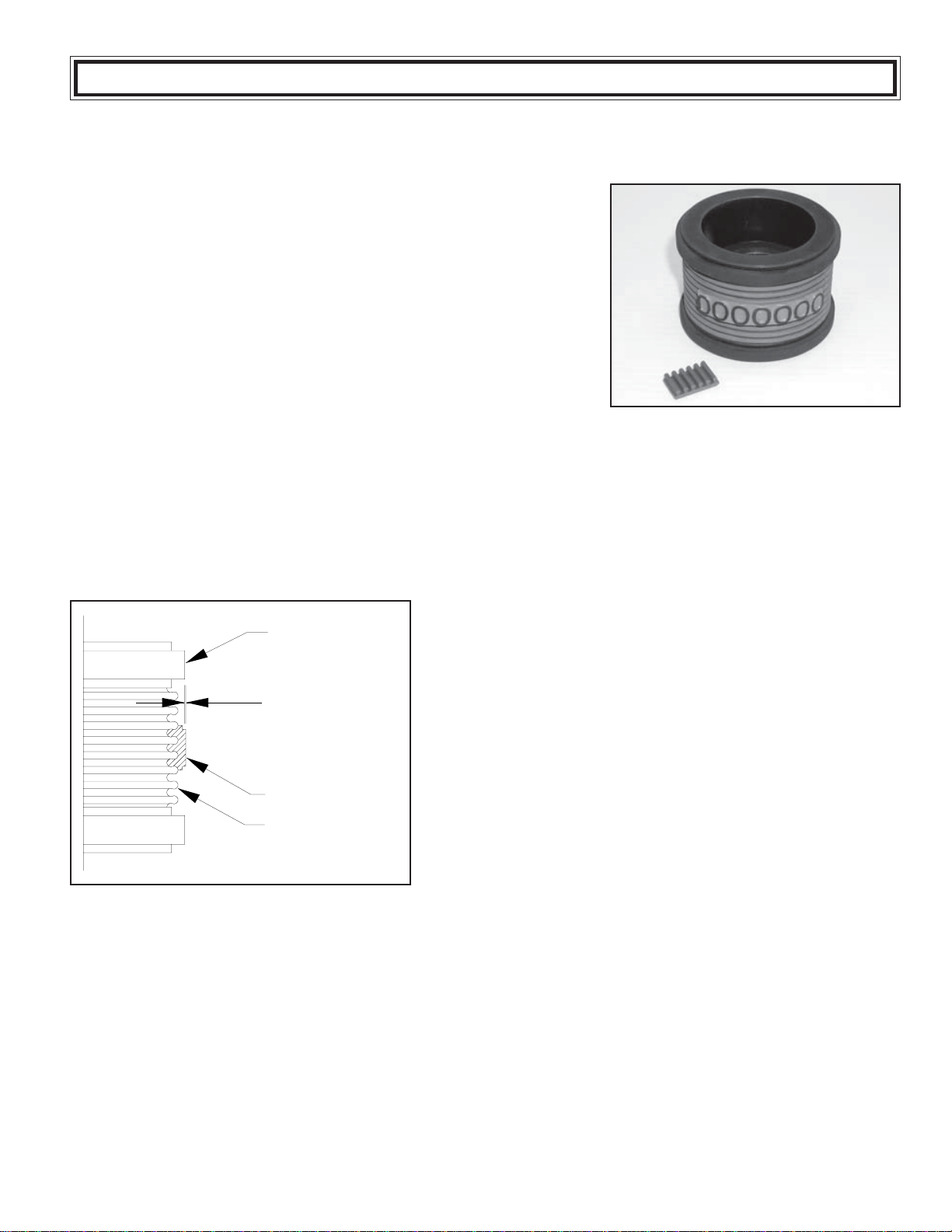

Ink Rolls

QUICK START

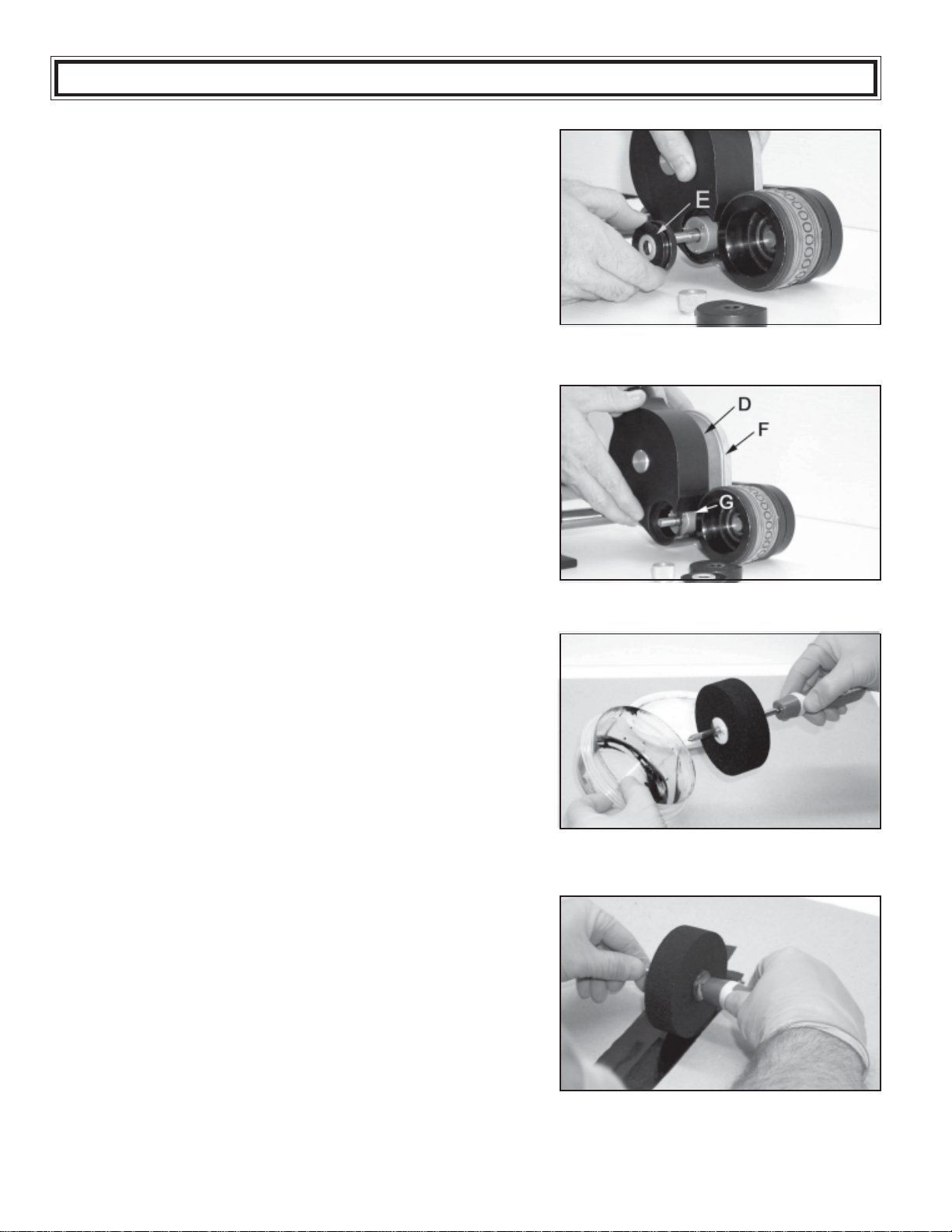

Installing the Pre-Inked Roll

Installing the Printing Dies

Adjusting the Ink Roll Eccentric

BASIC PRINCIPALS OF OPERATION

Inking System

Using the 4 oz. Reservoir Ink Cartridges

Selecting an Appropriate Ink

Ink Drying Time Considerations

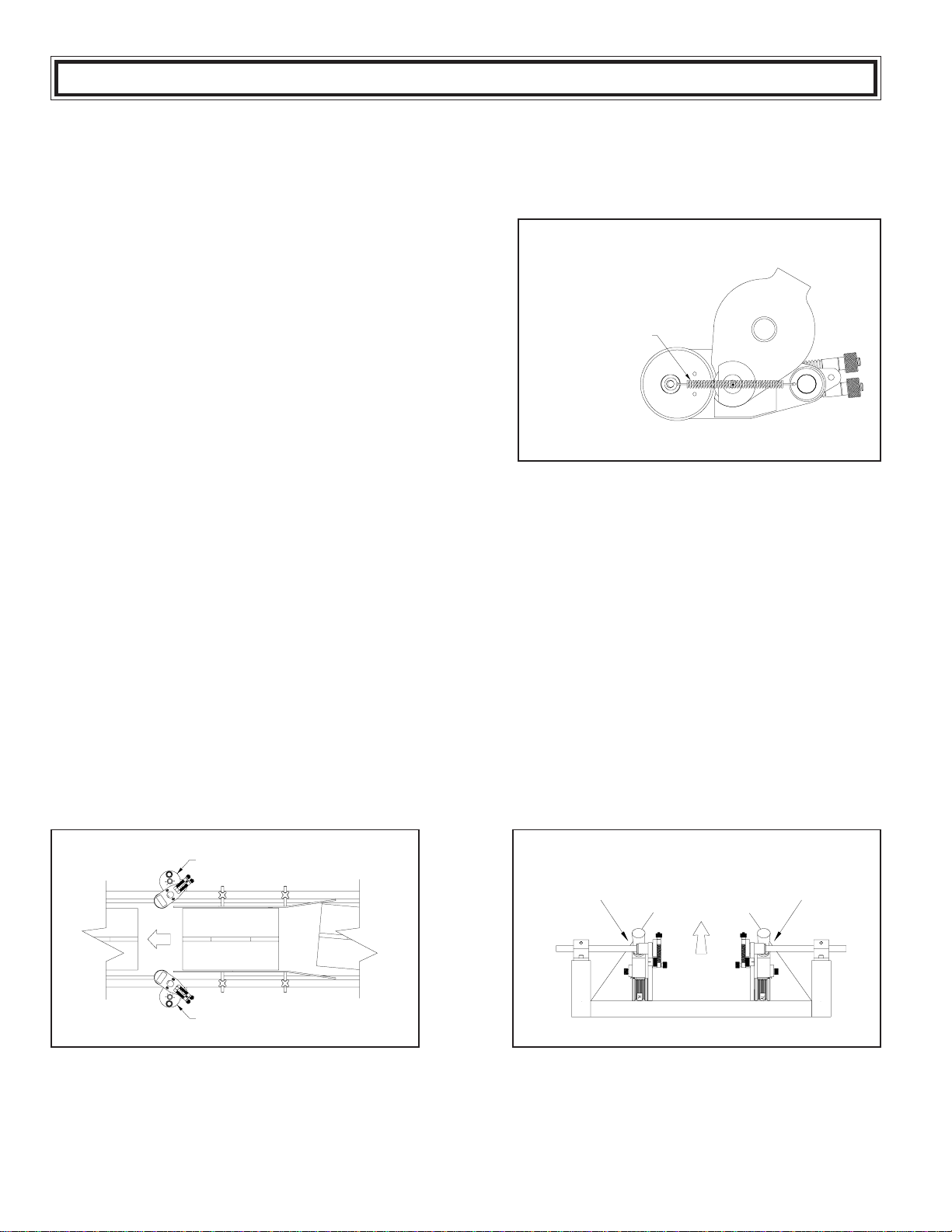

WEB PRINTING

Selecting a Place to Mount Your Coder

Special Web Printing Applications

Printing on Narrow Web Materials

Printing Directly on Master Rolls

CARTON PRINTING

Carton Alignment

DiePositioningforIndexingApplications

TRANSFERROLL/PRINTPRESSUREREADJUSTMENT

Adjusting the Transfer Roll Pressure

AdjustingPrintingPressure

MAINTENANCE

Pre-InkingaNewRoll

CleaningtheTransfer Roll

Cleaning the Coder

CleaningthePrintingDies

PARTSLIST&DIAGRAMS

IMPORTANT NOTE

UNIVERSAL products are manufactured to exacting standards and every available step has been taken to

assure your complete satisfaction. It is most important that the instructions contained in this manual are read

and carefully followed for best results. Failure to do so may result in unsatisfactory performance, damage to the

equipment and personal injury. TABLE OF CONTENTS 3

4

4

5

6

6

7

8

9

9

12

13

14

14

14

15

16

17

18

19

19

19

20

20

22

24

24

25

26

26

27

27

28

29

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

- LIMITED WARRANTY -

UNIVERSAL Non-Porous Mini-Coders are guaranteed to be free from defects in materials and workmanship for a

period of 90 days from the date of purchase. Components found to be defective during this time will be repaired free of

charge if returned to the factory. Damage resulting from use of improper inks, improper installation, or operation is not

covered under the scope of this warranty. For warranty service please contact our Customer Service Department.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○