TFP815

Page 5 of 6

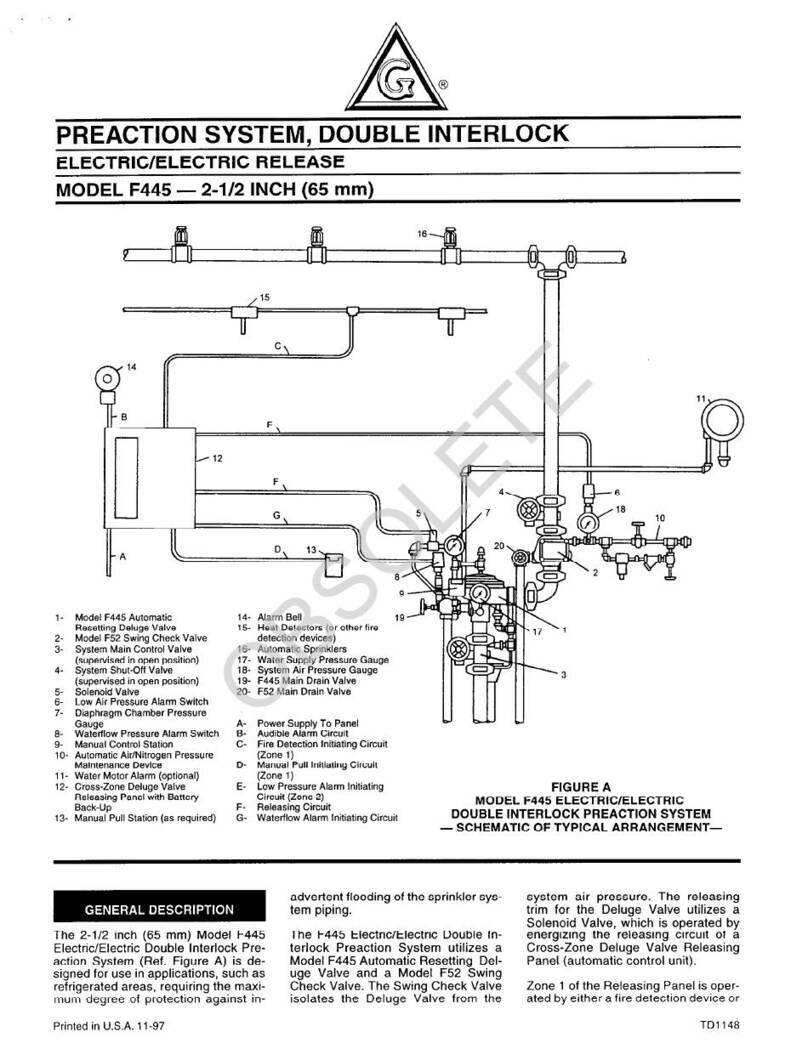

Design

Criteria

Nozzle Placement

The nominal overall spray patterns,

spacing, and maximum recommended

axial distances for six patterns of the

Type HV Nozzles are given in Figure 2

for residual (owing) pressures of 30

to 80 psi (2,1 to 5,5 bar). A minimum

residual pressure of 30 psi (2,1 bar) can

typically be used for most applications.

However, a minimum residual pressure

of 50 psi (3,4 bar) is recommended for

applications requiring higher velocity

water delivery, such as those speci-

fying rapid extinguishment of oil res

by emulsication.

With reference to Figure 2, use of the

“Design Spray Prole” for the “Design

Spray Area” will help assure that direct

impingement on all surfaces will occur.

The “Design Spray Area” shown at the

top Figure 2 - Part 2 of 2 on Page 4

consists of the square of length “S”

within the circular “Overall Spray Area”.

The maximum recommended axial

distances given in Figure 2 are based

on maintaining the specied spray

patterns under a maximum wind

condition of 15 MPH (24 km/h).

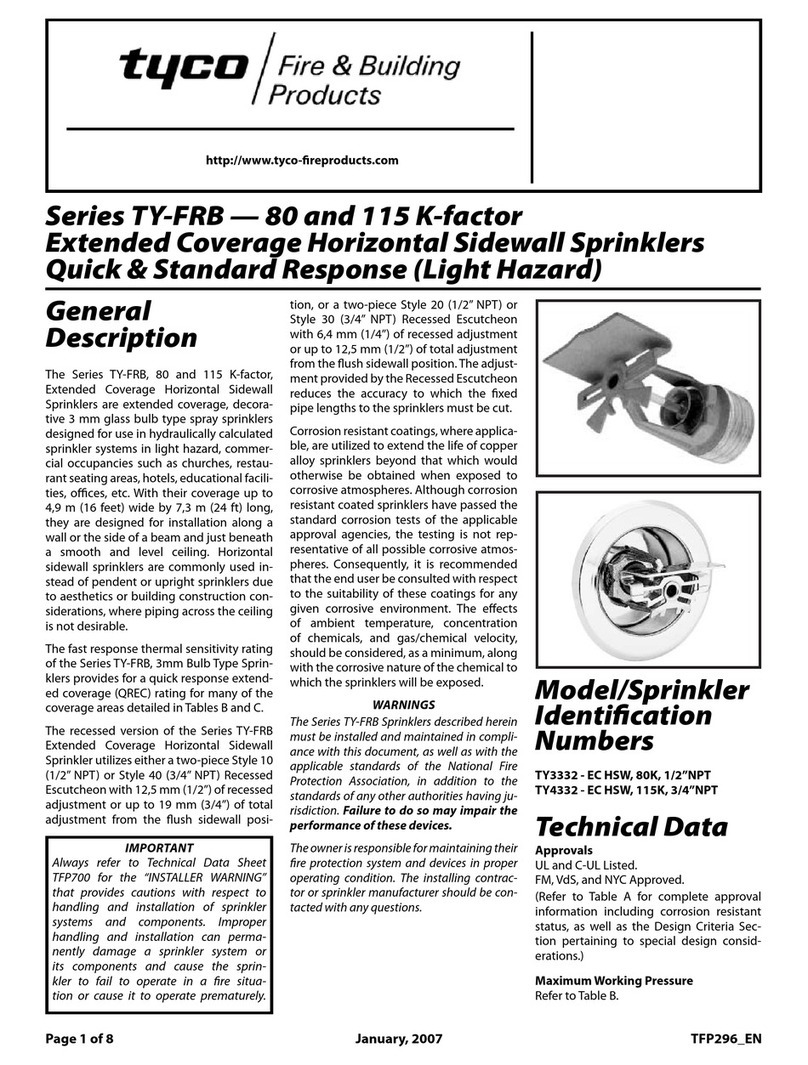

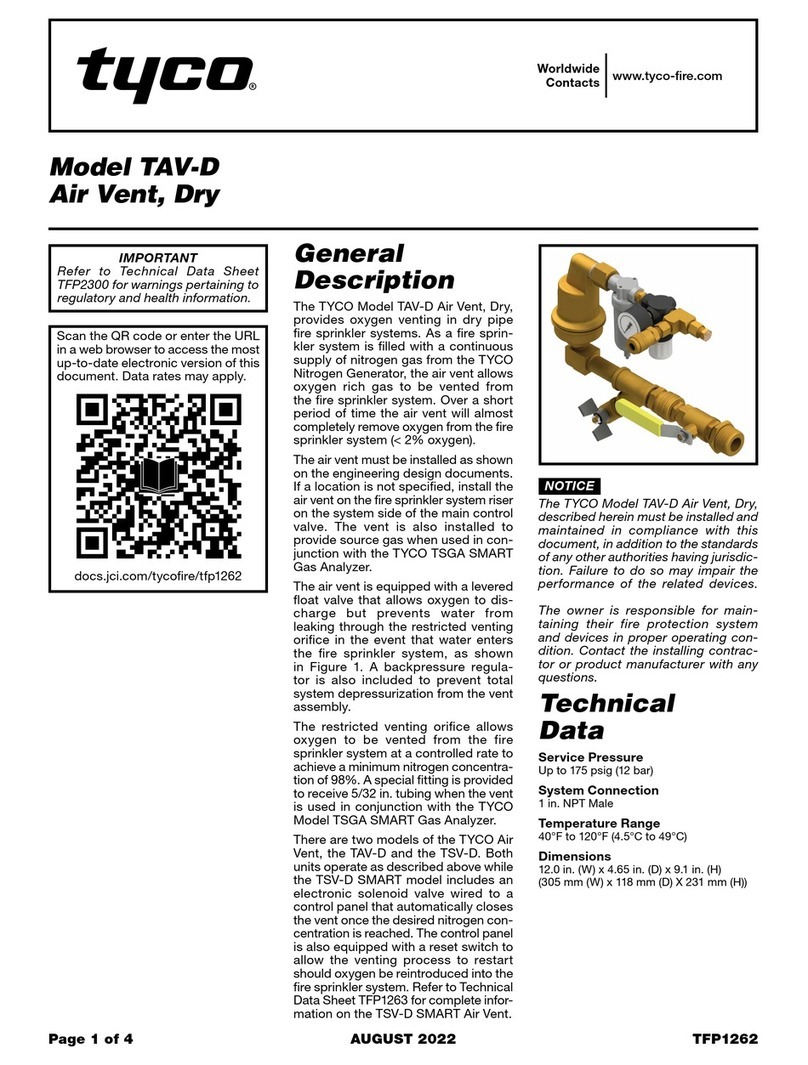

Figure 3 provides reference informa-

tion showing the overall still air spray

patterns beyond the maximum 15

MPH (24 km/h) axial distances, when

projecting horizontally.

As shown in Figure 3, the spray

patterns become non-concentric,

beyond a certain point, due to the

affects of gravity.

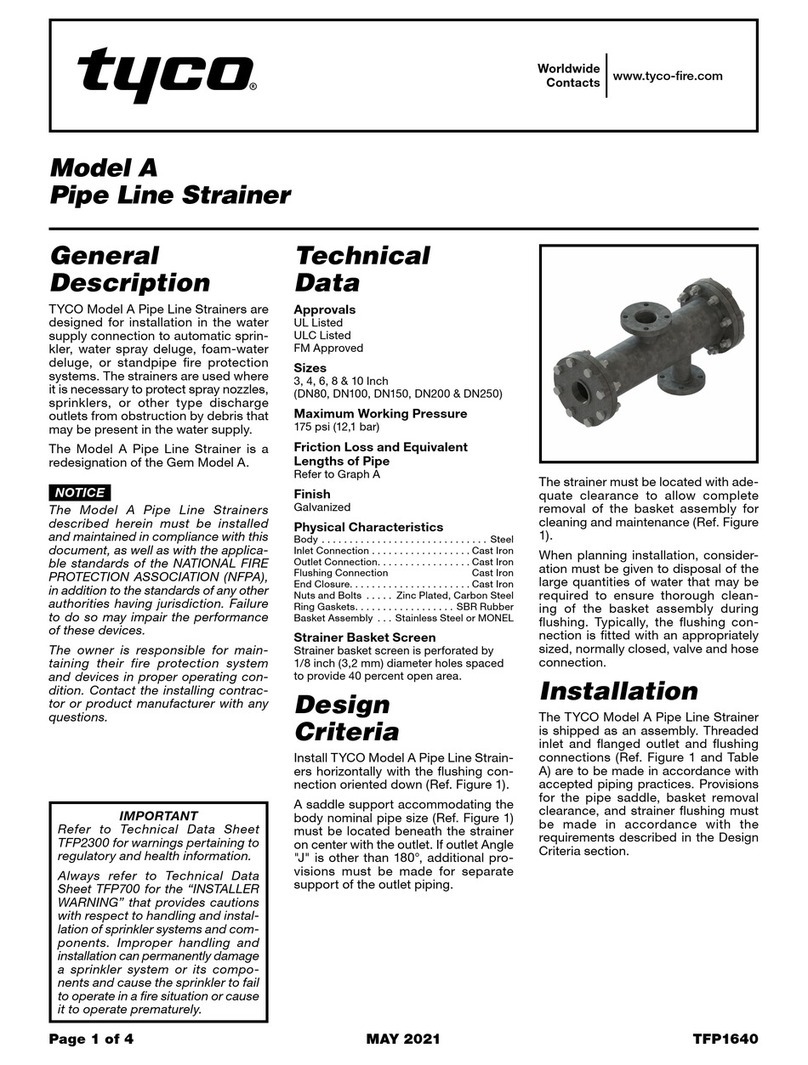

Main Pipeline Strainers

Even though individual strainers have

been provided, main pipeline strainers

are required for systems utilizing Type

HV Nozzles, since their waterways are

less than 3/8 inch (9,5 mm) diameter.

Installation

TYCO Type HV Nozzles must be

installed in accordance with this

section.

General Instructions

A leak tight 1 inch NPT nozzle joint

should be obtained by applying a

minimum to maximum torque of 20 to

30 ft.-lbs. (26,8 to 40,2 Nm). A leak tight

1-1/4 inch NPT nozzle joint shgould be

obtained by applying a minimum to

maximum torque of 30 to 40 ft.-lbs.

(40,2 to 53,6 Nm). Higher levels of

torque may distort the nozzle inlet and

cause impairment of the nozzle.

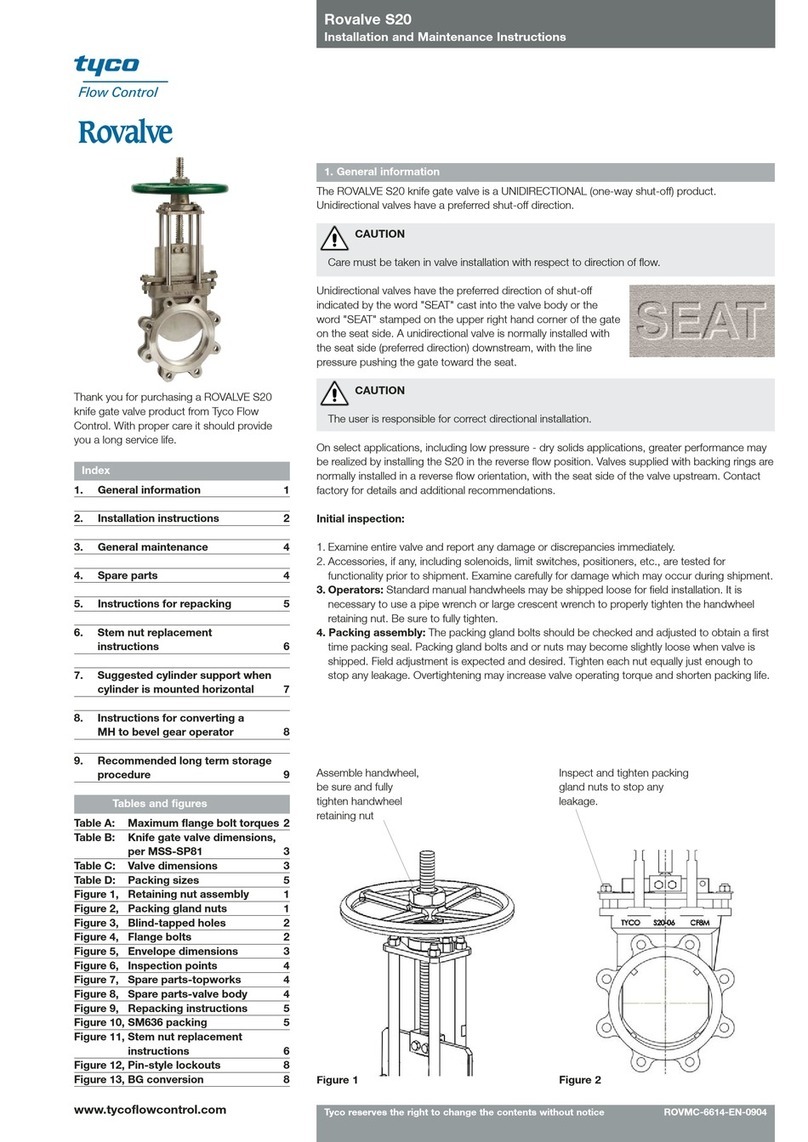

1.

With pipe thread sealant applied to

the pipe threads, hand tighten the

nozzle into the nozzle tting.

2.

Tighten the nozzle into the nozzle

tting using an adjustable crescent

wrench. With reference to Figure 1

the adjustable crescent wrench is to

be applied to the wrench hex.

Care and

Maintenance

The TYCO Type HV High Velocity

Nozzles must be maintained and

serviced in accordance with this

section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system

that it controls, obtain permission to

shut down the affected re protec-

tion system from the proper authorities

and notify all personnel who may be

affected by this action.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory.

Modied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers - before,

during, and after installation. Sprinklers

damaged by dropping, striking, wrench

twist/slippage, or the like, must be

replaced.

60

26

14

37

45

17

14

37

60

17 45

26

26

60

14

45

37

17

17

37

45

14

26

60

ELEVATION, METERS

HORIZONTAL DISTANCE, METERSHORIZONTAL DISTANCE, FEET

0

00,51,52,0 1,03,03,54,54,8 4,0 2,5

1,8

1,5

1,0

0,5

0,5

1,2

1,0

4,5 4,0 3,5 3,0 2,5 2,0 1,5 1,0 0,5

1,0

1,0

1,5

1,8

0

04,8

0246810121416

16 14 12 10 8 6 4 2 0

6

4

2

0

2

4 4

2

6

4

2

0

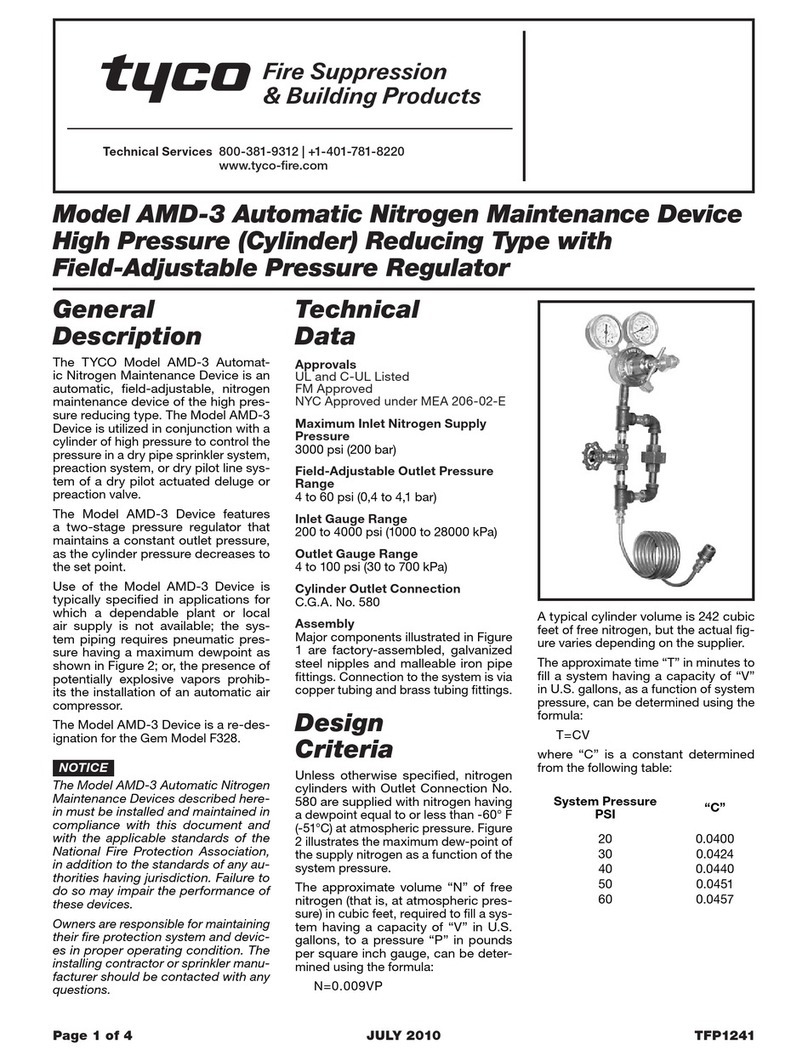

1.

2.

Reference data applies to still air.

The Overall Spray Patterns in the plan view are the same as those in Figure 2, Part 1.

FIGURE 3

TYPE HV NOZZLES

OVERALL VERTICAL SPRAY PATTERNS WHEN PROJECTING WATER

HORIZONTALLY BEYOND THE DESIGN PARAMETERS IN FIGURE 2

30 to 80 PSI (2,1 to 5,5 bar)