Falk®Rigid Moment Couplings •Installation & Maintenance

Type MCF •Size 1135 (Page 1 of 4)

Rexnord CP3-006

5555 S. Moorland Rd., New Berlin, WI 53151-7953 February 2015

Telephone: 262-796-4060 Fax: 262-796-4064 www.rexnord.com NEW

How to Use This Manual

This manual provides detailed instructions on installation,

removal, maintenance, and part descriptions. Use the table

of contents below to locate required information.

Table of Contents

Introduction ................................Page 1

Installation ...........................Pages 1 thru 3

Removal...................................Page 3

Annual Maintenance .........................Page 4

Part Descriptions ...........................Page 4

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS

MANUAL FOR OPTIMUM PERFORMANCE AND

TROUBLE-FREE SERVICE.

Introduction

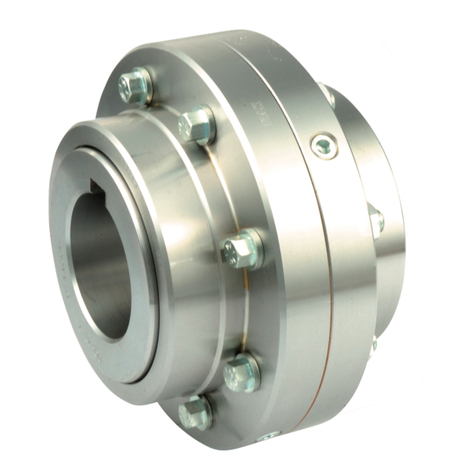

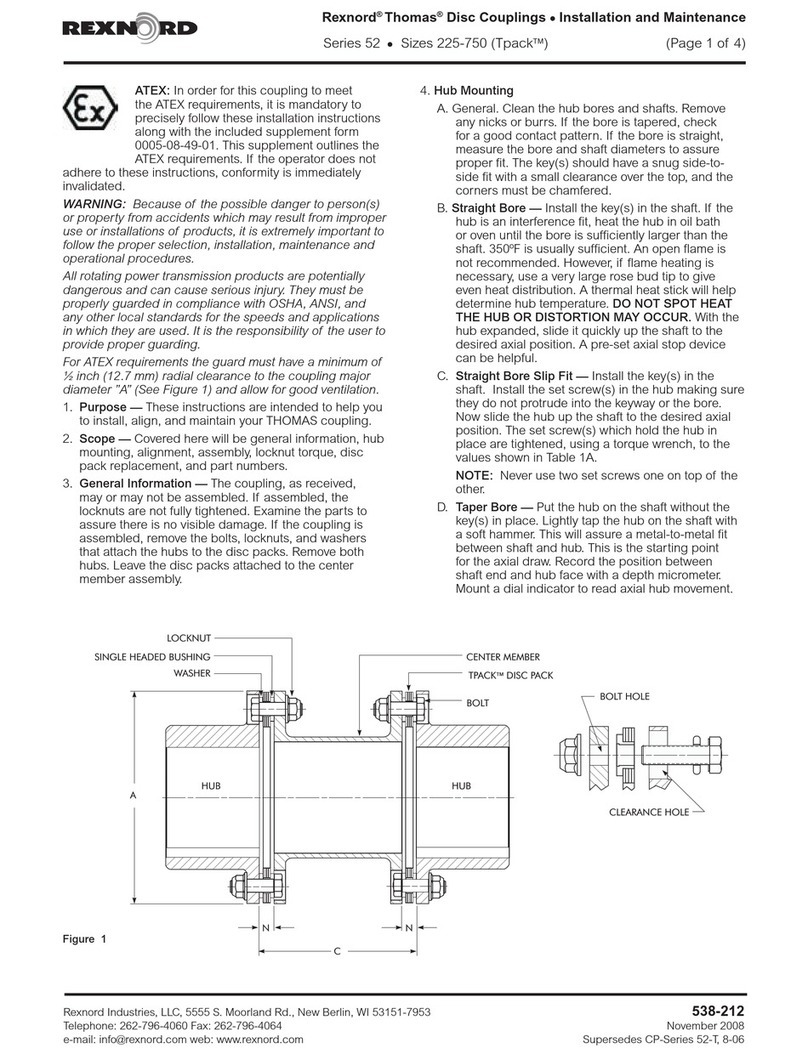

This manual applies to Type MCF rigid moment couplings,

size 1135. The couplings are designed to shaft mount

a gear drive to a shaft. The couplings will generally be

mounted horizontally but they can be mounted vertically

as well. MCF couplings are available with interference fit

hubs with key (Type 2), keyless interference fit hubs with

hydraulic removal (Type 6), or a combination of Type 2 and

Type 6 hubs. See Figure 1.

The performance and life of couplings depend largely

upon how you install and service them.

WARNING: Consult applicable local and national safety

codes for proper guarding of rotating members. Observe

all safety rules when installing or servicing couplings.

WARNING: Lockout starting switch of prime mover and

remove all external loads from drive before installing or

servicing couplings.

WARNING: Do not service the coupling without

first completely reading installation, alignment, and

maintenance instructions. The compressive fit between

the shaft and hub provides both support for the drive

assembly and transmits the torque. Failure to achieve

correct fit between the shaft and hub, and between the two

hubs, can result in damage to the system components and

has the potential to cause serious injury to personnel in the

immediate vicinity.

WARNING: Visual movement of the drive and assembly

is normal. The movement is due to shaft and coupling

connection runout. DO NOT restrain this movement; to do

so will adversely load the reducer low-speed shaft and the

connected shaft, and may result in shaft or hub failures.

Installation

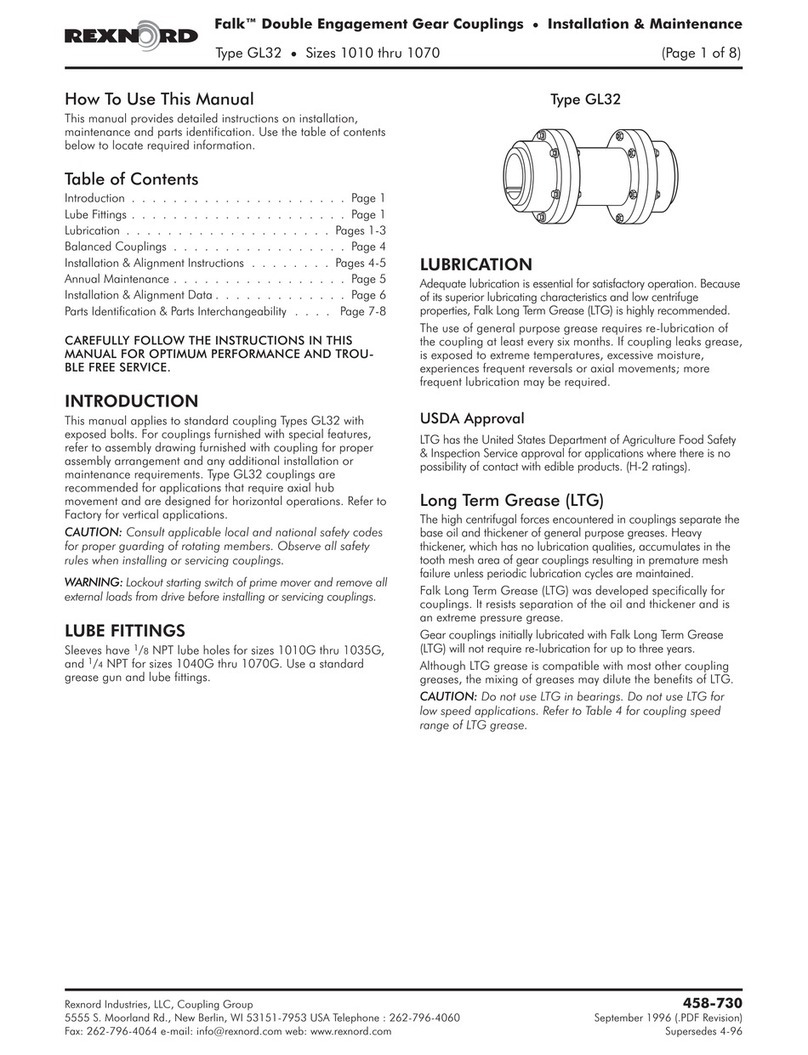

1. Thoroughly clean, degrease, and dry coupling hub

flange mounting faces, drive and driven shafts. Clean

with a non-flammable solvent. See Figure 2.

2. Check both shafts for runout to ensure shafts are not

bent. Refer to Figure 4.

3. Shaft ends must be chamfered to provide a lead for hub

mounting.

4. Shafts and bores must be free of burrs. Any rust or

corrosion in the interference area must be removed

before assembly.

5. If a key seat is present in the driven shaft, the edges of the

key seat should be broken with a file and free of burrs.

6. Mount hubs on shafts.

a. Clean all parts. Heat hub to between 450°F (232°C)

and 500°F (260°C) using an oven, torch, or an

induction heater.

WARNING: Do not use an oil bath to heat hub.

When an oxy-acetylene or blow torch is used, use an

excess acetylene mixture. Mark hub near the center

of its length in several places on hub body with

temperature-sensitive crayons, one 450°F (232°C)

and one 500°F (260°C) melt temperature. Direct

flame toward hub bore using constant motion to

avoid overheating an area.

b. Mount hub flush with face of shaft. Allow hub to cool

before proceeding. Refer to Figure 4.

PREVAILING

TORQUE

LOCKNUT

HEX SOCKET

PIPE PLUG

HEX HEAD

CAP SCREW

KEYLESS

FIT HUB

INTERFERENCE

FIT HUB WITH KEY

Figure 1 — TYPE 2 FEMALE HUB & TYPE 6 MALE HUB

IMPORTANT

CAREFULLY CLEAN

SHAFT & HUB BORE

& KEEP FREE OF

ANY GREASE HUB

DEGREASE

FAC E

Figure 2