2

UNIVERSALproductsaremanufacturedtoexactingstandardsandeveryavailablestephasbeentakentoassure

your complete satisfaction. It is most important, however, that the instructions contained in this manual are read

and carefully followed for best results. Failure to do so may result in unsatisfactory performance, damage to the

equipment and personal injury.

IMPORTANT NOTE

- LIMITED WARRANTY -

UNIVERSALWPNP-400NI-PIDSDigitalWebPrintersareguaranteedtobefreefromdefectsinmaterialsandworkmanship

foraperiodof90 days from thedateofpurchase. Componentsfoundto be defective duringthistimewillberepaired free of

charge if returned to the factory. Damage resulting from use of improper inks, improper installation, or operation is not

coveredunder the scopeofthis warranty. For warranty serviceplease contact our CustomerServiceDepartment.

PREFACE

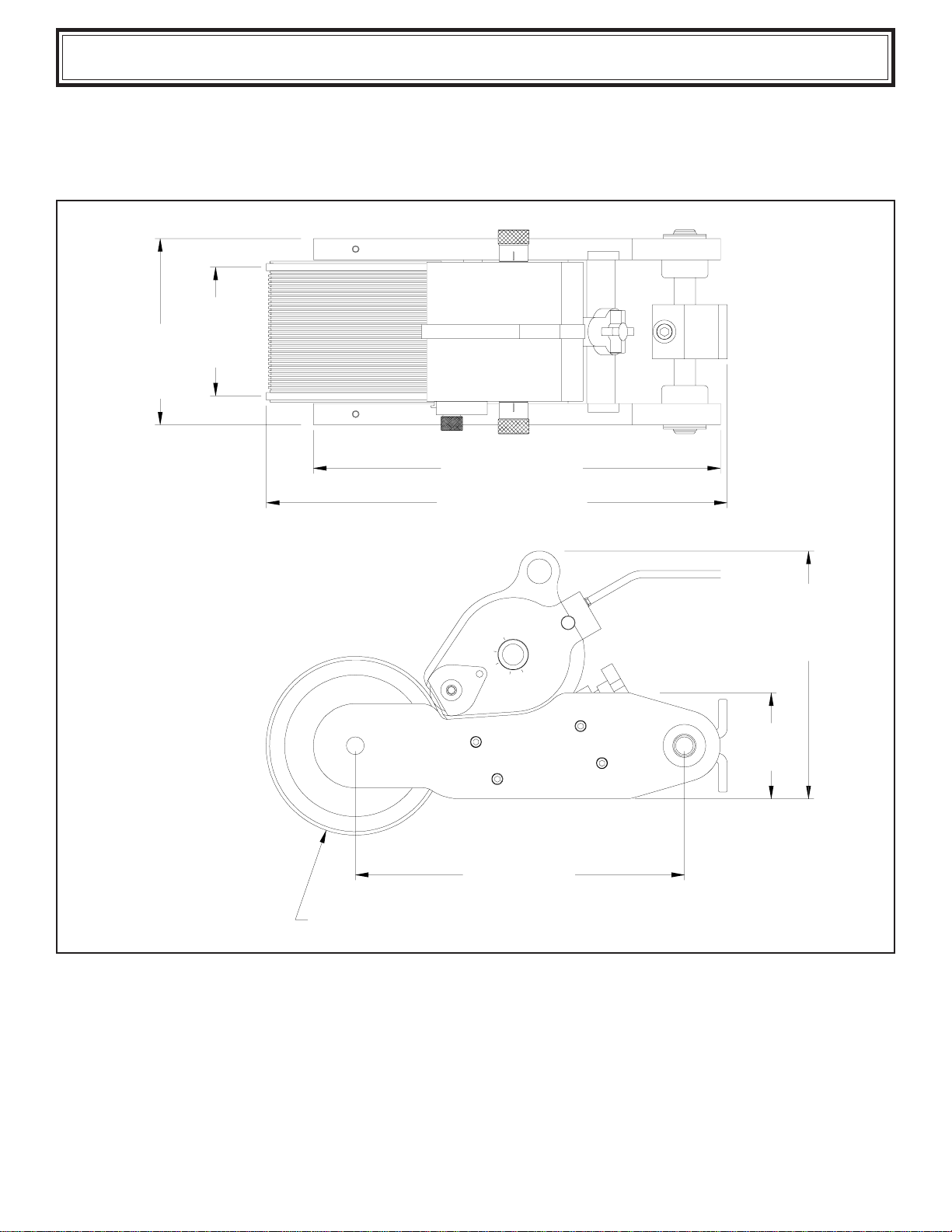

SPECIFICATIONS

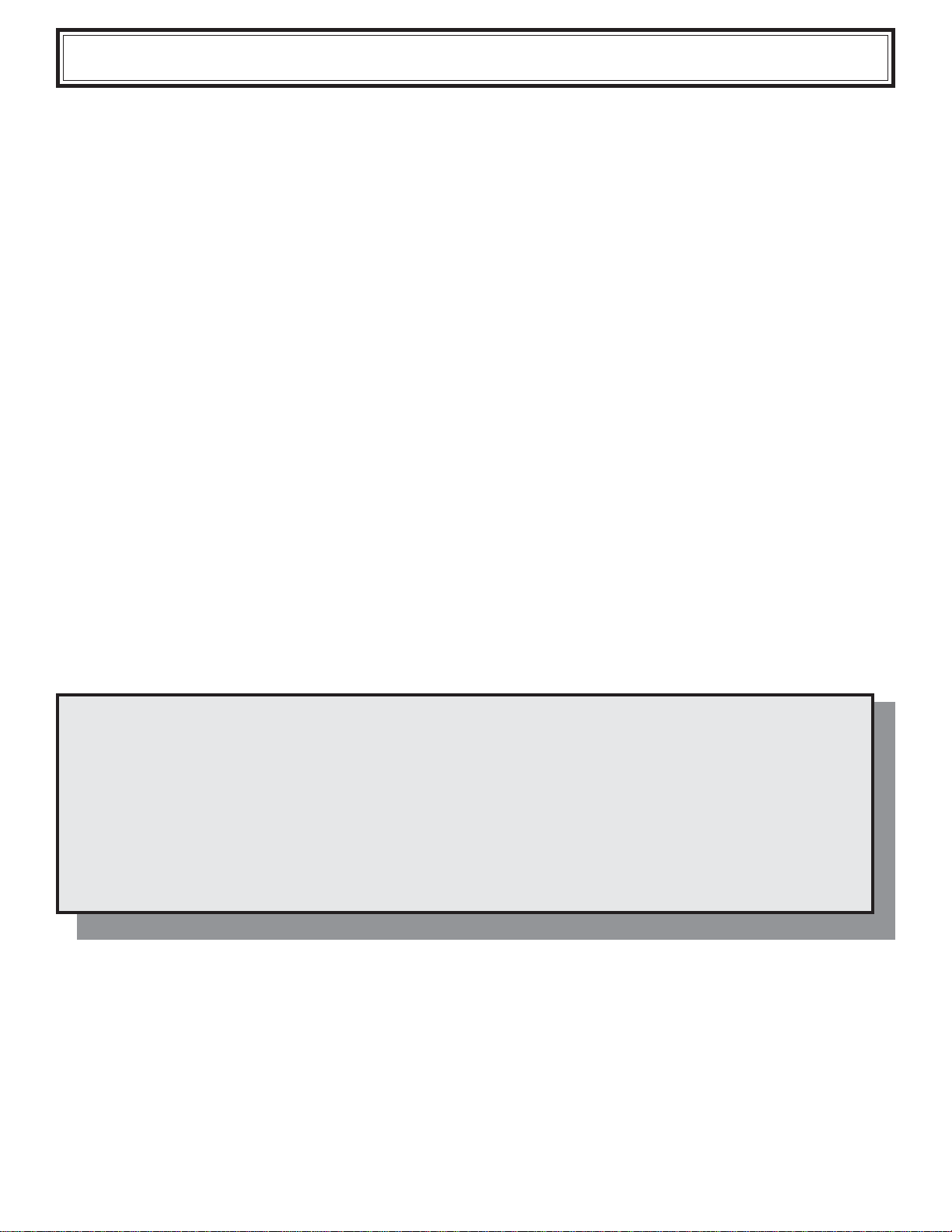

WPNP-400NI-PIDS&WPNP-400NI-T-PIDS

WPNP-400NI-PIDS-D & WPNP-400NI-T-PIDS-D

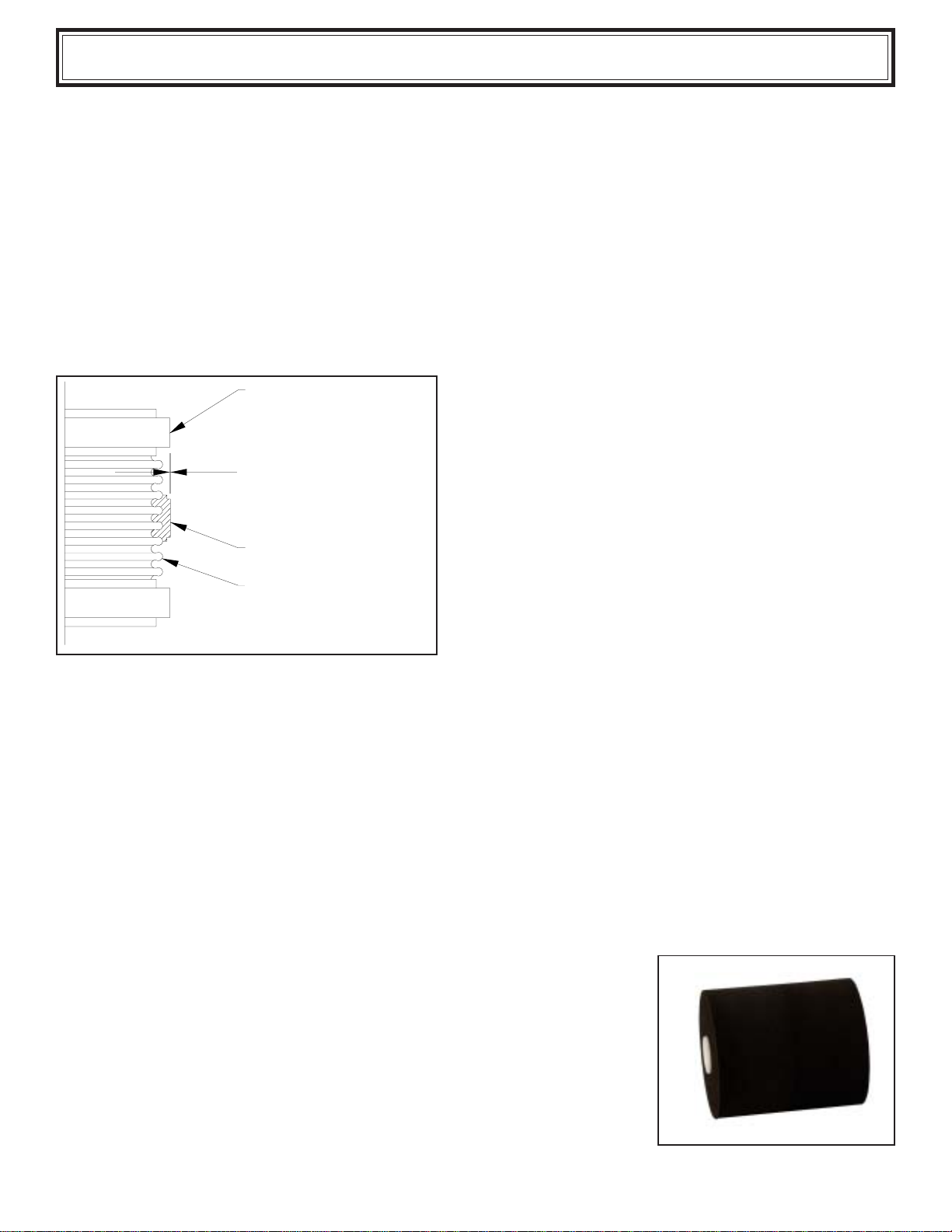

Printing Dies

XFNeopreneInkRolls

QUICK START

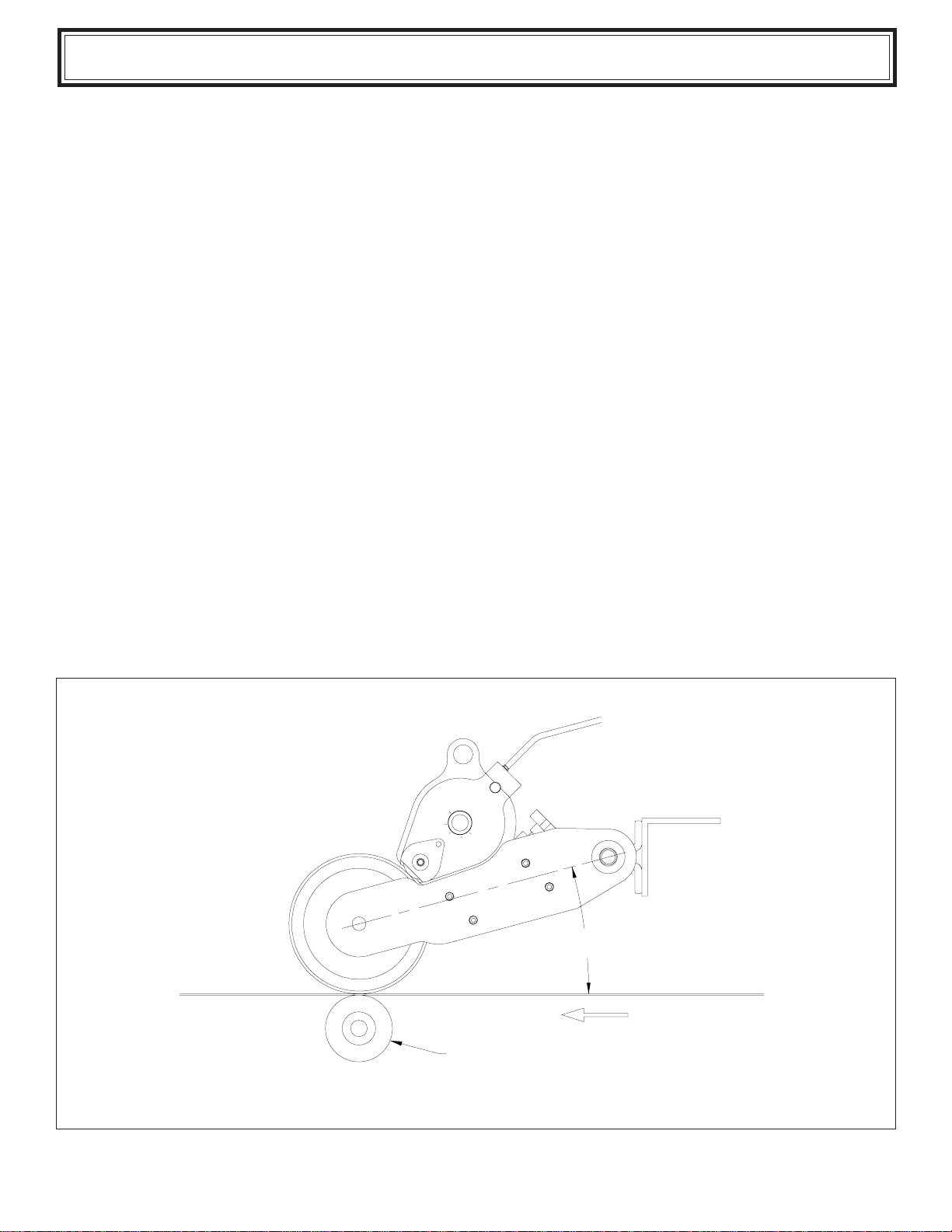

InstallingthePrinter

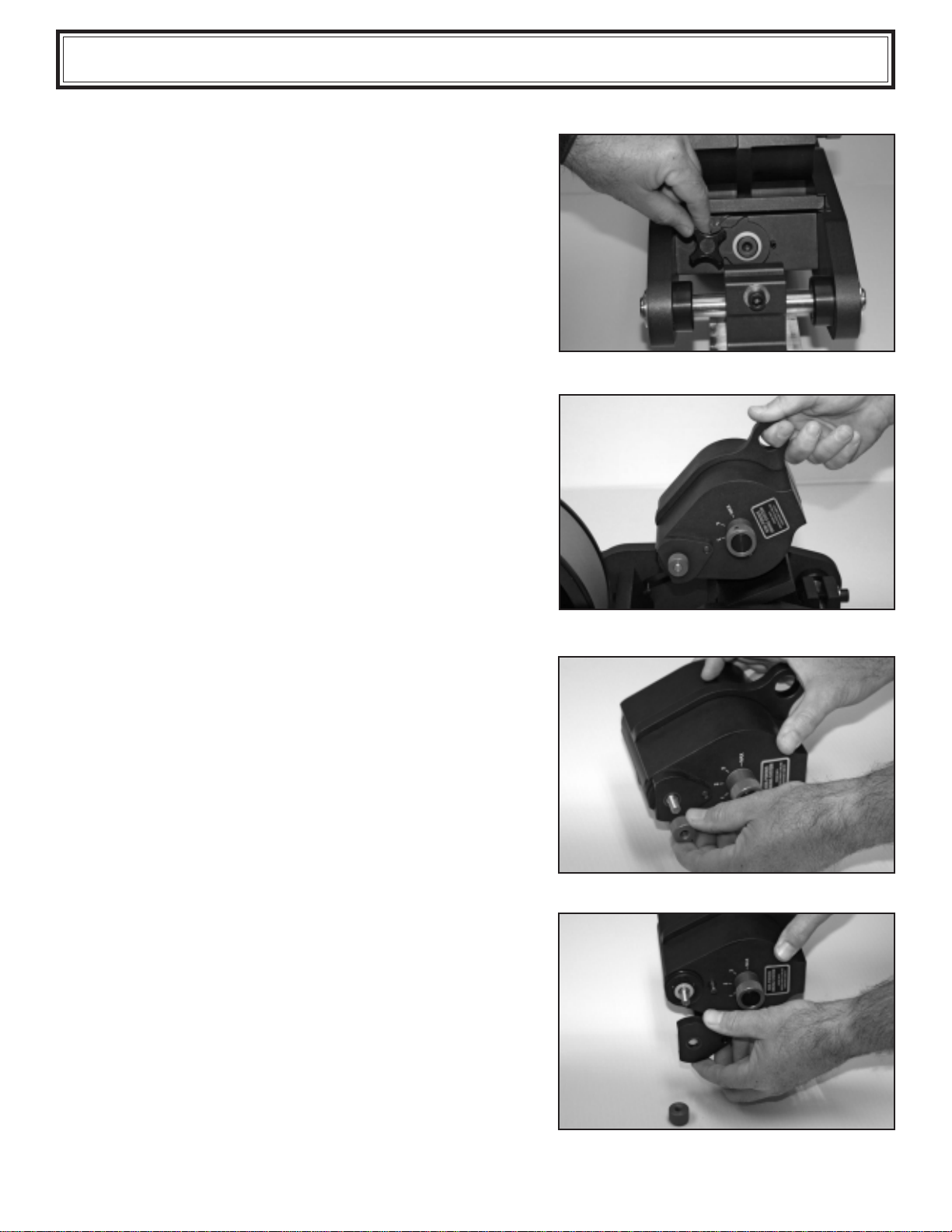

Preparing the Printer for installation of the Ink Roll

Preparing the Ink Roll for installation

InstallingtheInkRoll

Reinstalling the Inking System on the Printer

Installing the Printing Dies

Inking System PositionAdjusting Knobs

Pre-InkingtheXFNeopreneInk Roll

BASIC PRINCIPLES OF OPERATION

The Pids System

Pids-Digital-CE Programmable Ink Delivery Systems

WPNP Web Printer Interval Timer Setting

Endcoder Sensory Assembly

Installation orAdjustment of the Inductive Proximity Sensor

MAINTENANCE

Cleaning the Printer

Cleaning the Transfer Roll

Cleaning the Printing Dies

PARTS DIAGRAMS & PARTS LISTS

3

4

4

5

5

6

7

9

10

12

13

13

14

15

15

15

16

16

18

18

19

20

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○