2.1 Components

F20 smart sintering furnace is a sintering equipment suitable for zirconia

restorations crystallization.

The temperature in the chamber can be heated up to 1600 degree, and it

is controlled intelligently by the corresponding control system and control

software during sintering, and the target and actual temperature in the furnace

can be displayed in real time.

The F20 smart sintering furnace includes

the following components:

- 1 sintering furnace body

- 1 hearth base and 1 hearth

- 3 sintering tray with cover

- 1 pack of sintering beads

- 1 sintering tweezers

- 1 power cord

02 Product Description

5) No objects can be placed on the top of F20, and no liquids are

allowed to enter the interior;

6) F20 works at a high temperature, so it needs good ventilation.

Do not use it in a humid environment to avoid abnormal accidents;

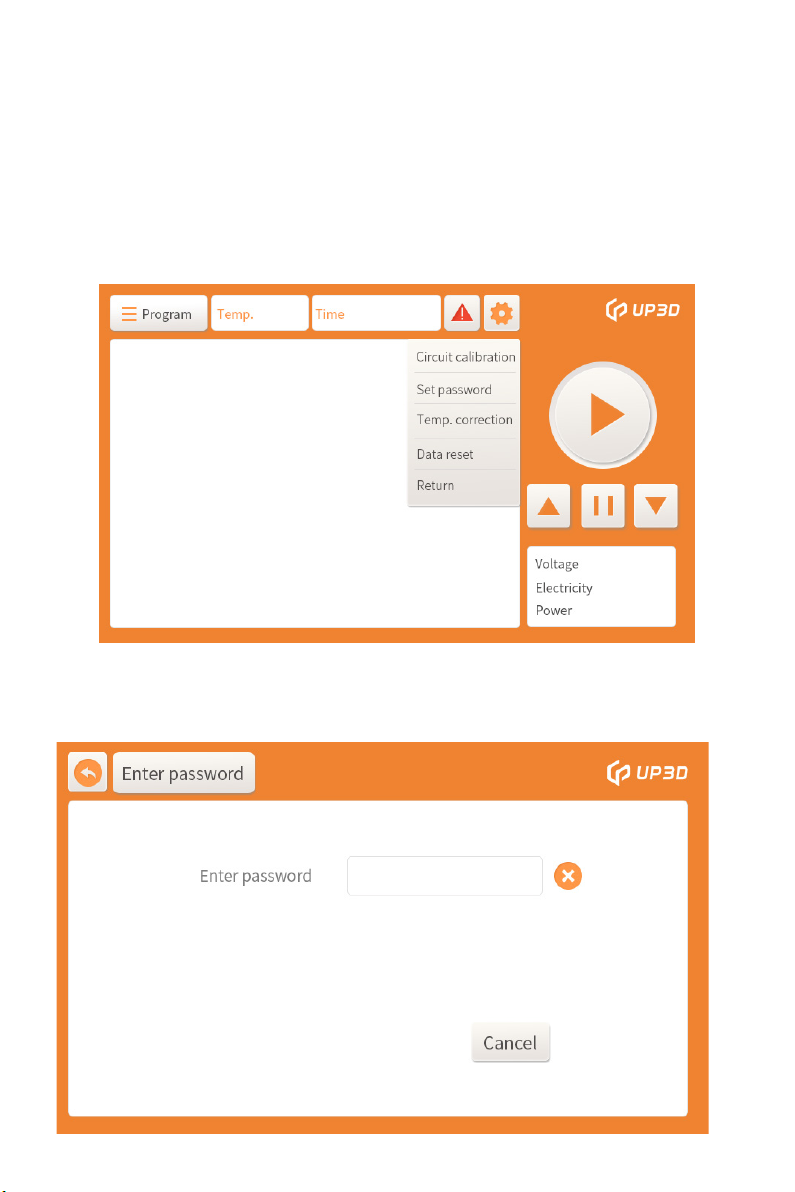

7) When using the F20, pay attention to the operating conditions,

and the faulty pop-up window needs to be resolved in time;

8) When cleaning and maintaining the F20, the power must be cut

off, and do not carry out with electricity;

If you lose the manual, you can contact technical support of UP3D

TECH to get it