Page 3800.633.3047

Plastic Identification – Can I Use the Hot Air Welder?

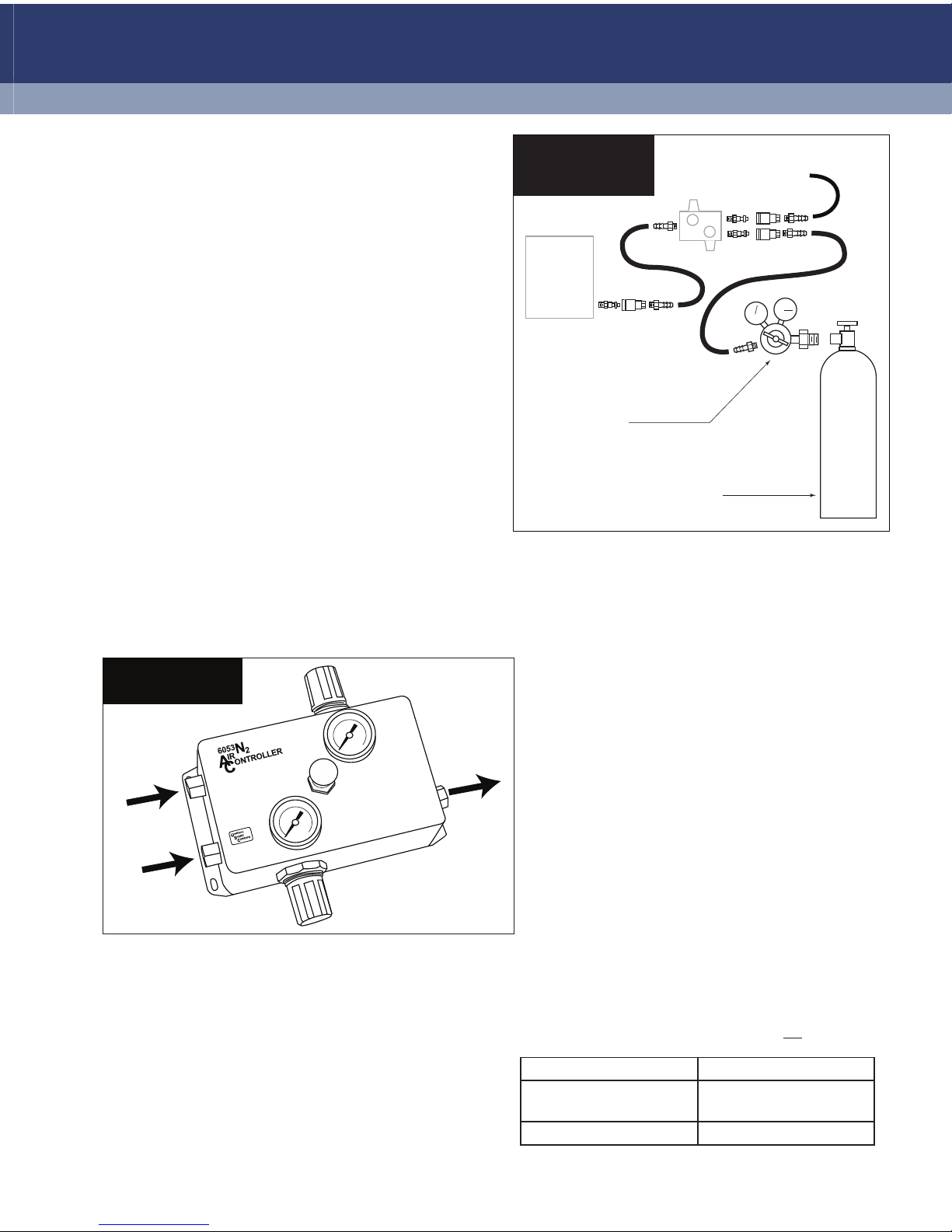

N2

6053

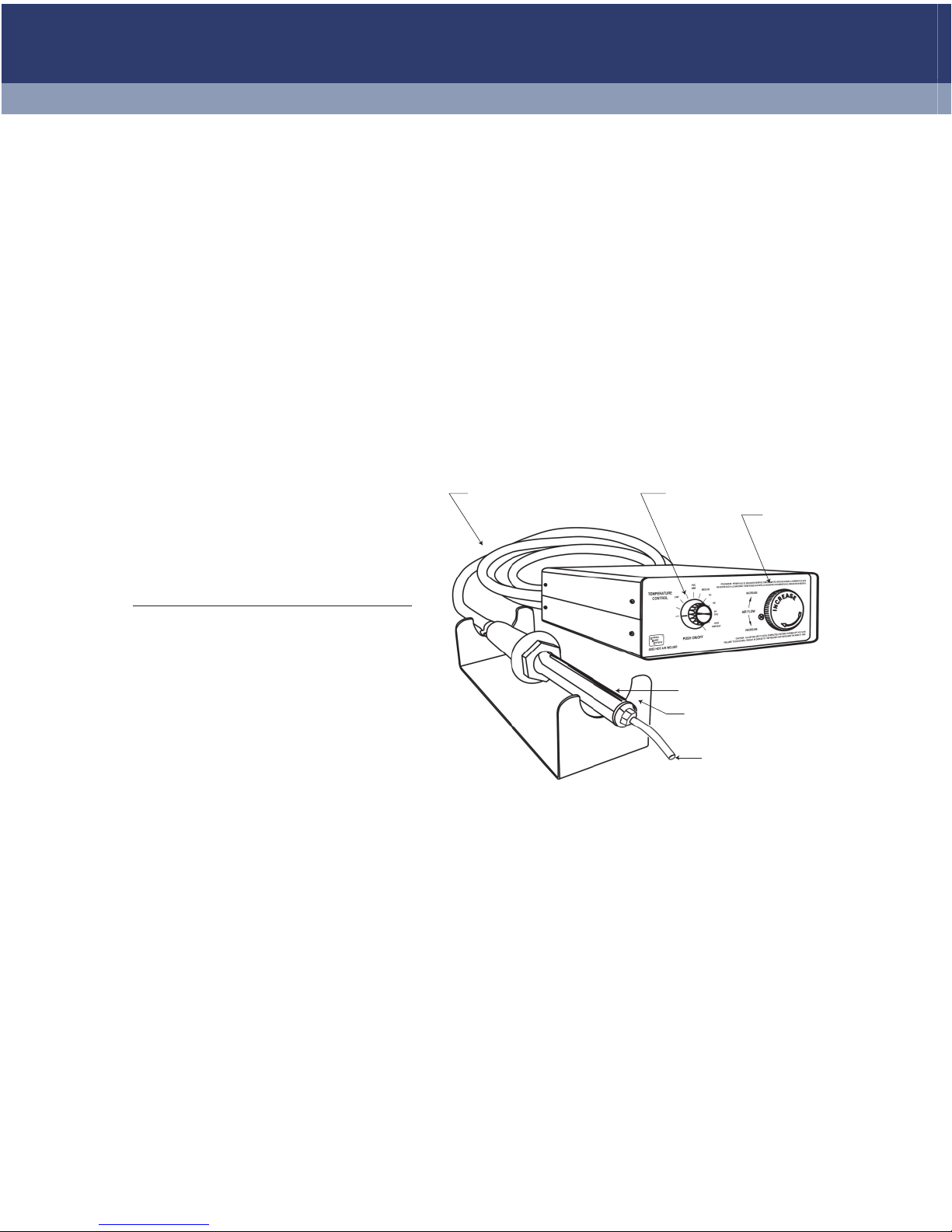

Hot Air

Welder

6053N2

Nitrogen-Air

Controller

Regulator (not supplied)

Purox R-36, P/N 21364

by ESAB Welding Products

(or similar)

Nitrogen bottle (not supplied)

rent from local welding supply

Compressed

Air

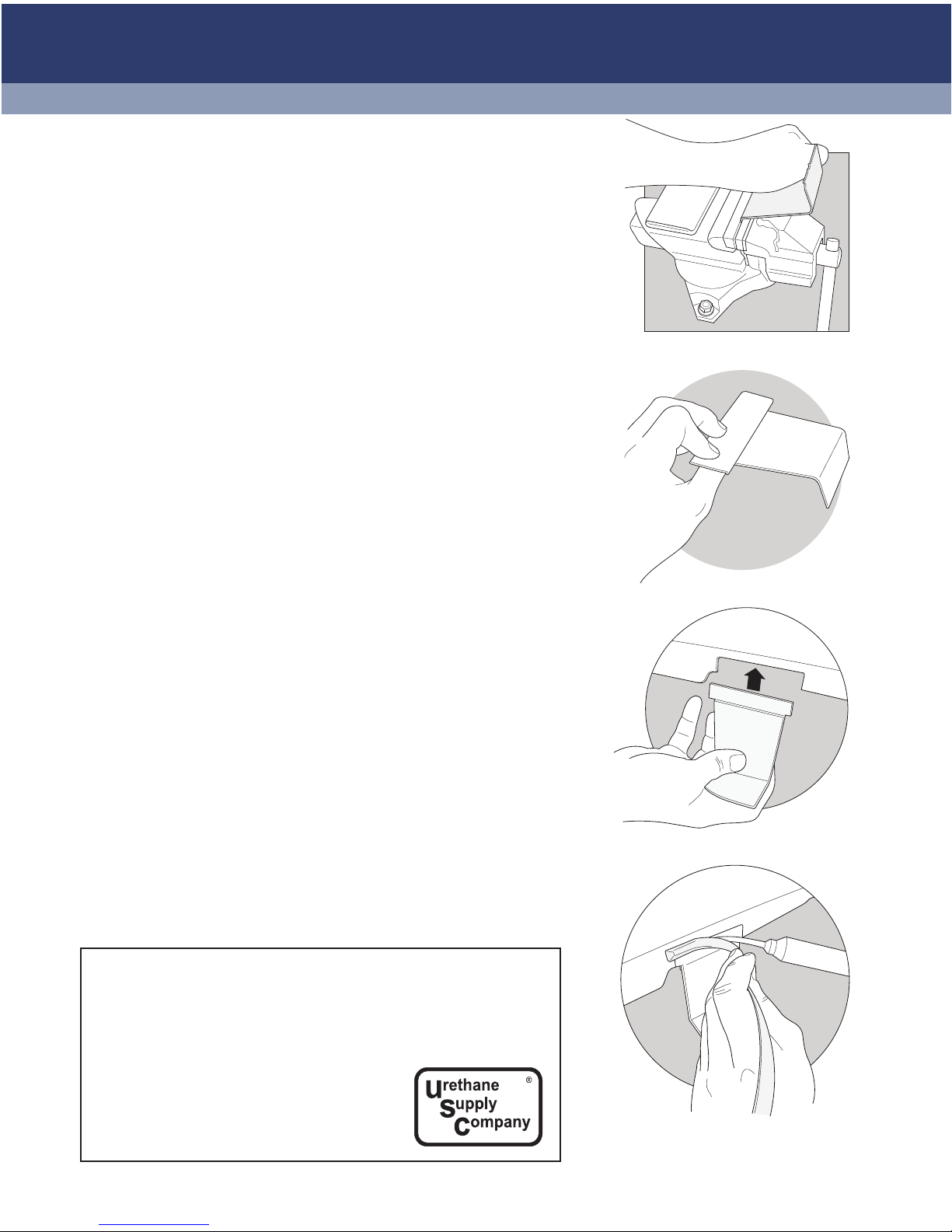

6053 / 6053N2

Setup Schematic

Push for Air

Pull for Nitrogen

Set up:

6KRS DLU 086TEH GU\ DQG RLOIUHH

5HJXODWH VKRS DLU DQG QLWURJHQ VXSSO\ WR

WKH VDPH SUHVVXUH ZKHQ VHOHFWRU NQRE LV

LQ HLWKHU SRVLWLRQ

TKHUH VKRXOG EH QR SHUFHSWDEOH FKDQJH

LQ DLU SUHVVXUH ZKHQ WKH VHOHFWRU YDOYH LV

LQ HLWKHU SRVLWLRQ

Use:

3XVK VHOHFWRU NQRE LQ WR ³DLU´ ZKHQ ZDUPLQJ RU

FRROLQJ WKH ZHOGHU RU ZKHQ WKH ZHOGHU LV LGOH

3XOO VHOHFWRU NQRE WR ³QLWURJHQ´ ZKHQ ZHOGLQJ

)RU EHVW UHVXOWV DOORZ WR VHFRQGV DIWHU

QLWURJHQ LV RZLQJ WR SXUJH DLU RXW RI WKH OLQH

EHIRUH ZHOGLQJ

1128 Kirk Rd.

Rainsville, AL 35986

ph: (800) 633-3047

www.urethanesupply.com

AIR

N

2

Air

Inlet

Nitrogen

Inlet

Outlet to

Hot Air

Welder

Balance pressure

regulators - adjust

to 40-50 psi

6053N2 Nitrogen-

Air Controller

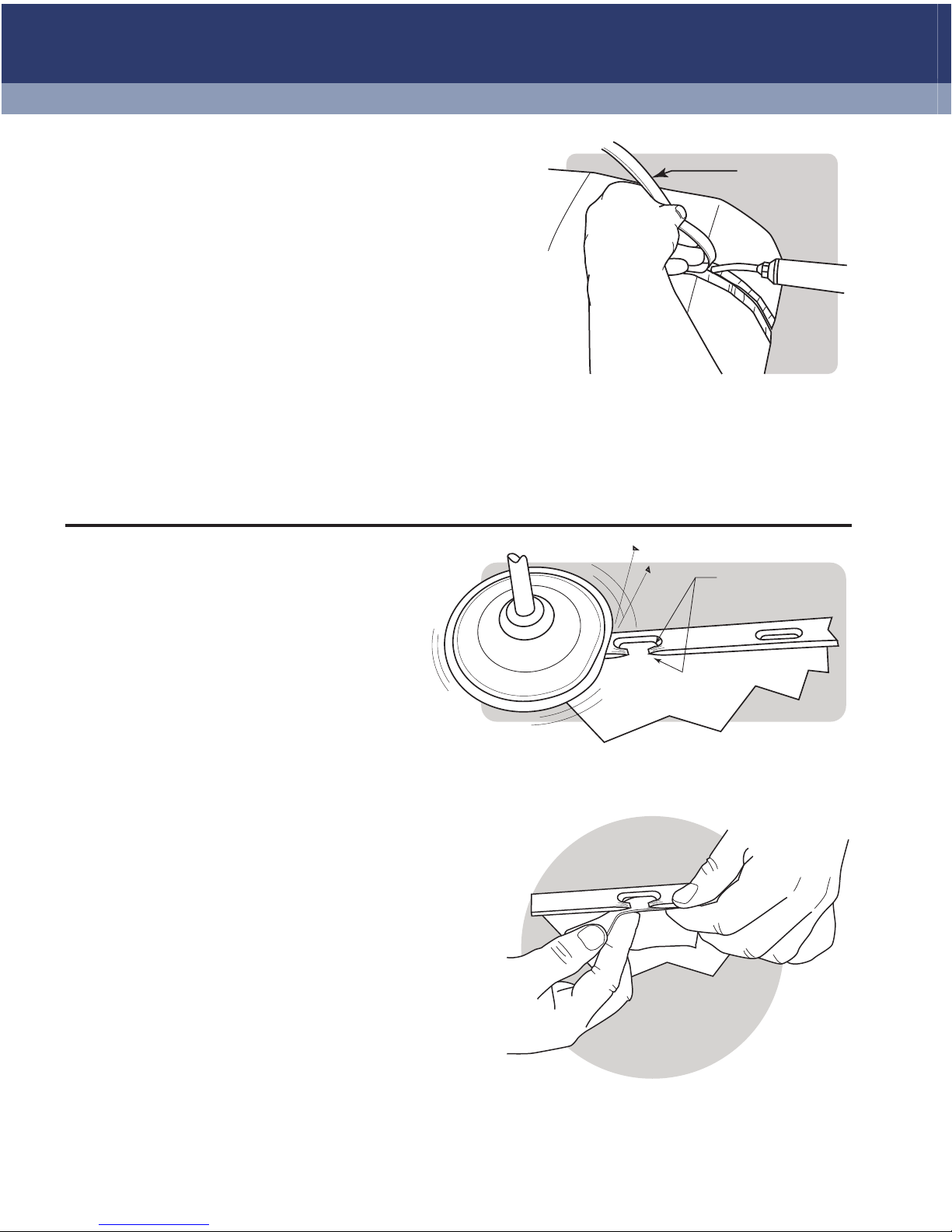

Type of plastic Hot air weldable?

PP, PP/EPDM, TEO, TPO,

TSOP, PE, ABS, PA, PC YES

PUR, SMC, UP, fiberglass NO