Environmental

Parameter Value Units

Operating Temperature -20 to 100 C

Electrostatic Discharge, IEC 61000-4-2

Single-ended (-S version)

Differential (-D version) ± 12

± 7 kV

Shock, 6 millisecond, half-sine 75 G

Vibration (20Hz to 2kHz, sinusoidal) 20 G

Mechanical

Parameter Value Units

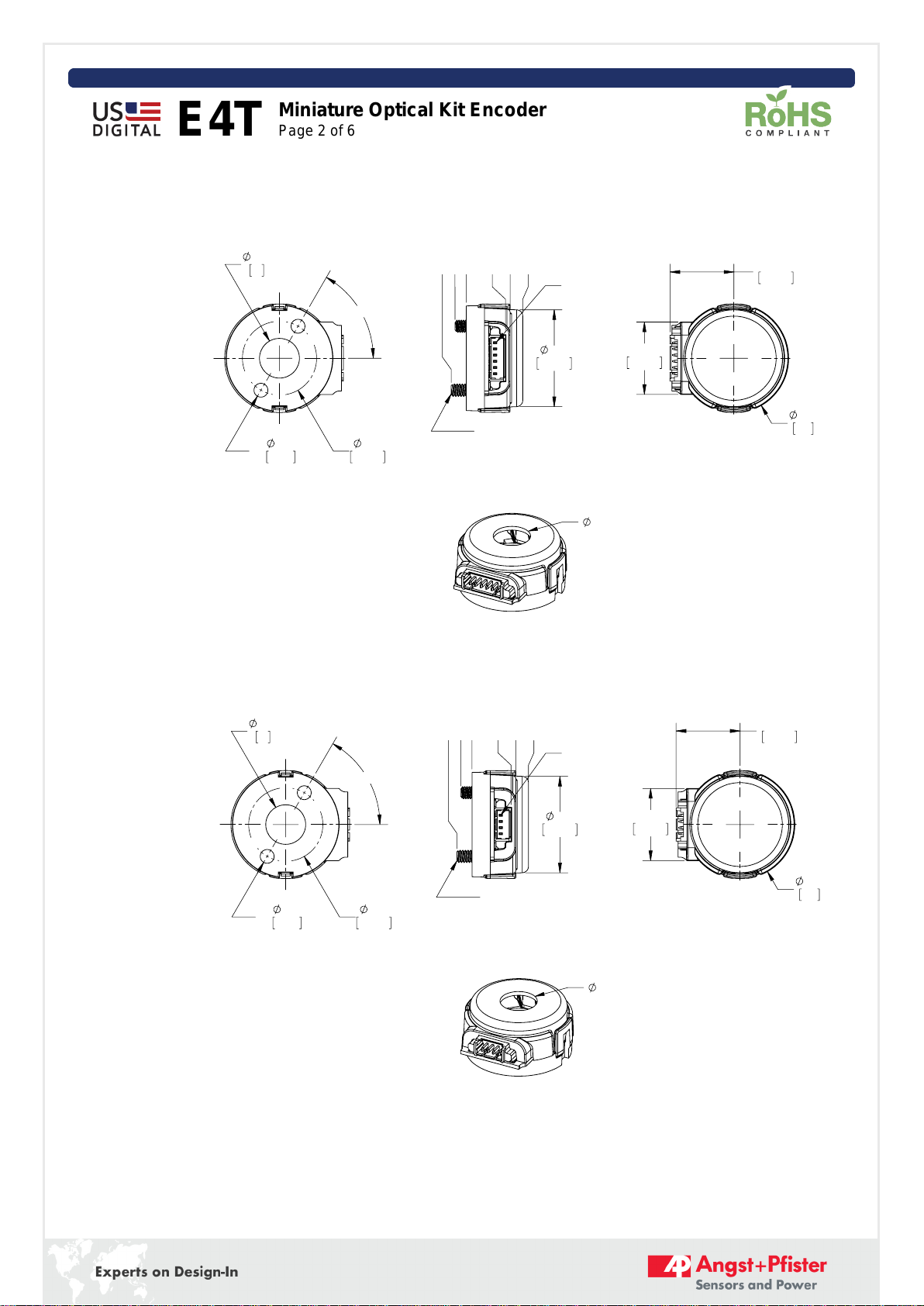

Max. Shaft Axial Play ± .010 in.

Max. Shaft Runout (TIR) .002 in.

Max. Acceleration 250,000 rad/sec²

Maximum RPM (1)

e.x. CPR = 300, max. rpm = 20000

e.x. CPR = 200, max. rpm = 30000

minimum value of

(6000000/CPR)

and (60000)

RPM

Max. Codewheel Moment of Inertia 5.1 x 10^-7 oz-in-s²

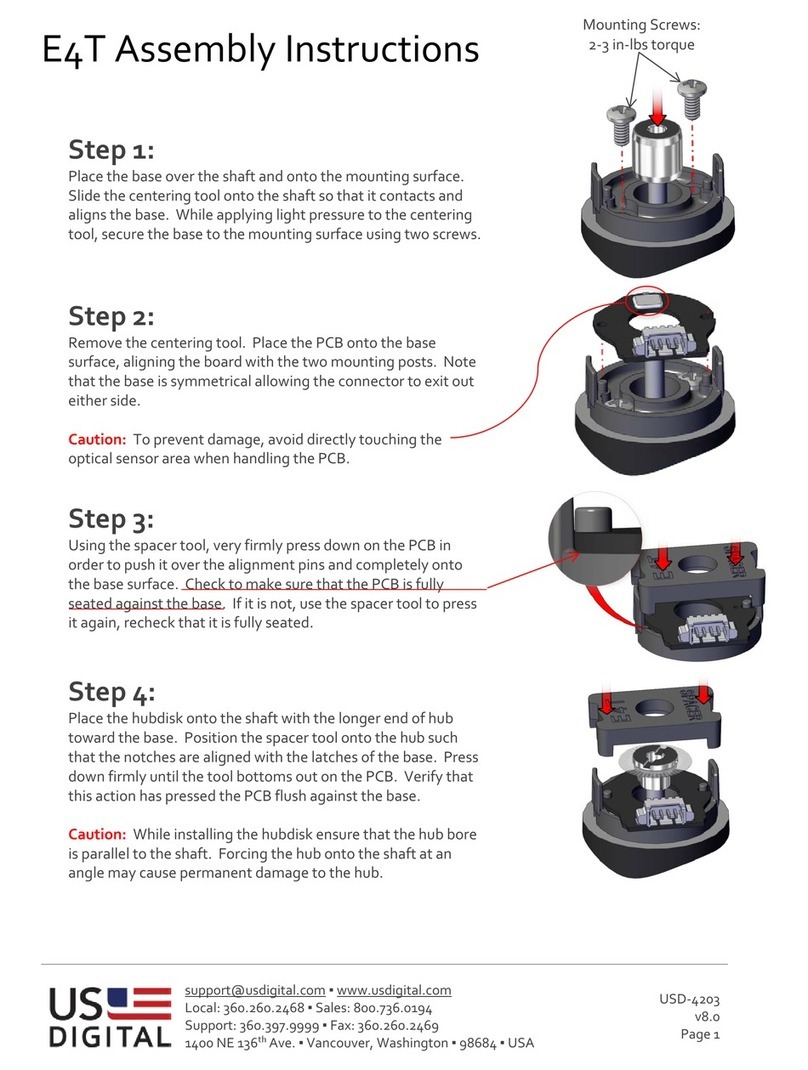

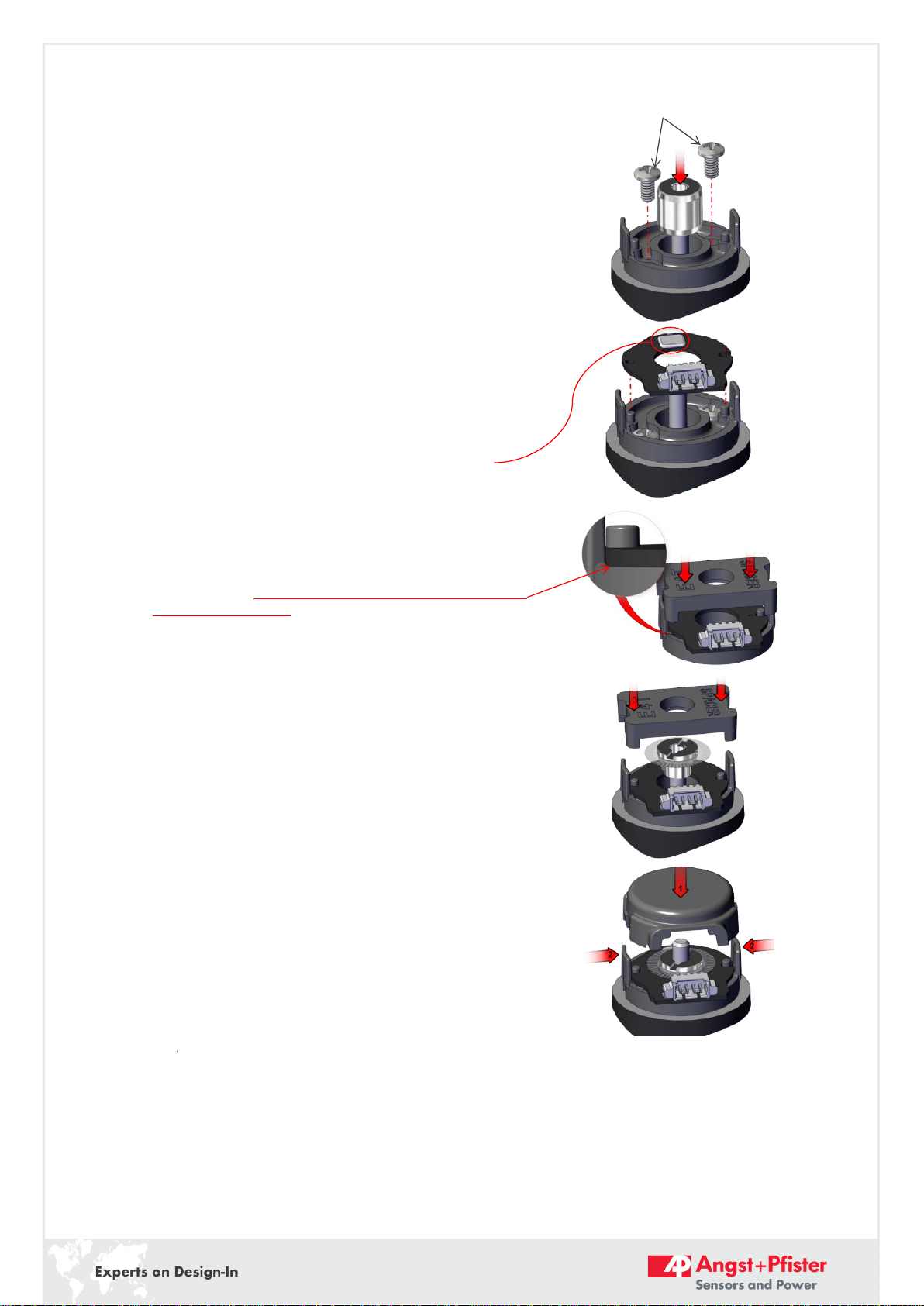

Mounting Screw Size

Default (D-option base)

Metric (M-option base) #3-48 x 3/16"

M2.5, length 4mm

Screw Bolt Circle Diameter .586 ±.005 in.

Minimum Shaft Length (2) .275 in.

Maximum Shaft Length (2) .395 (D option) /

no limit (H option) in.

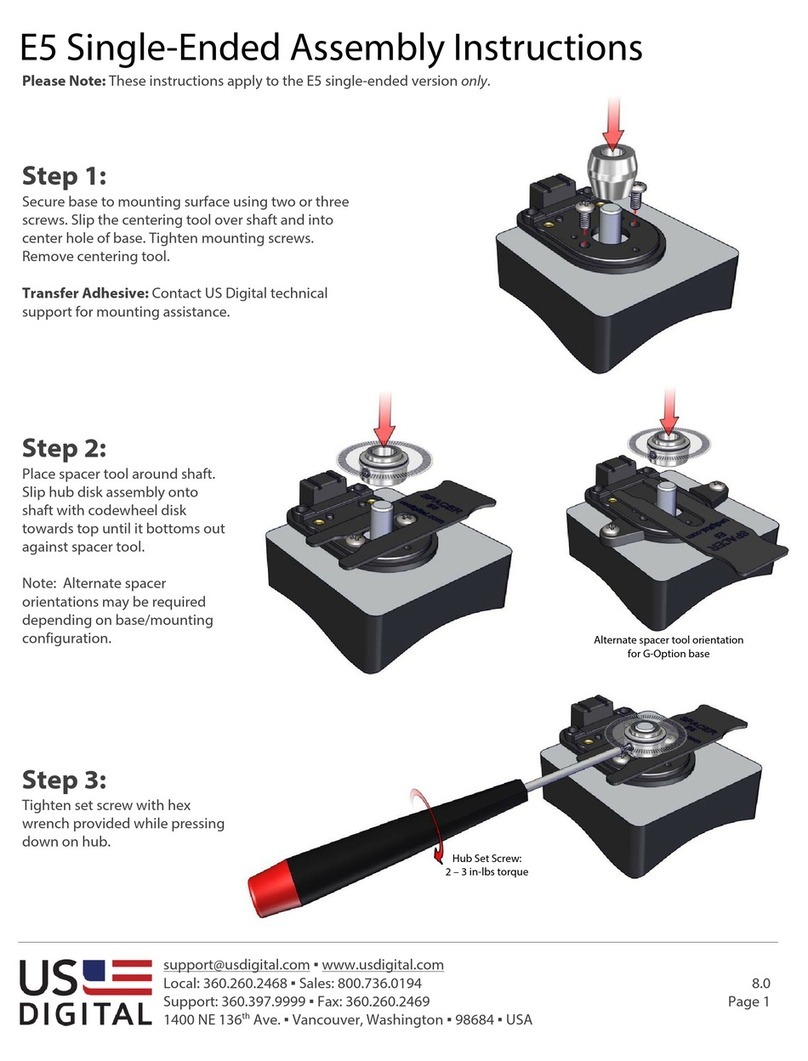

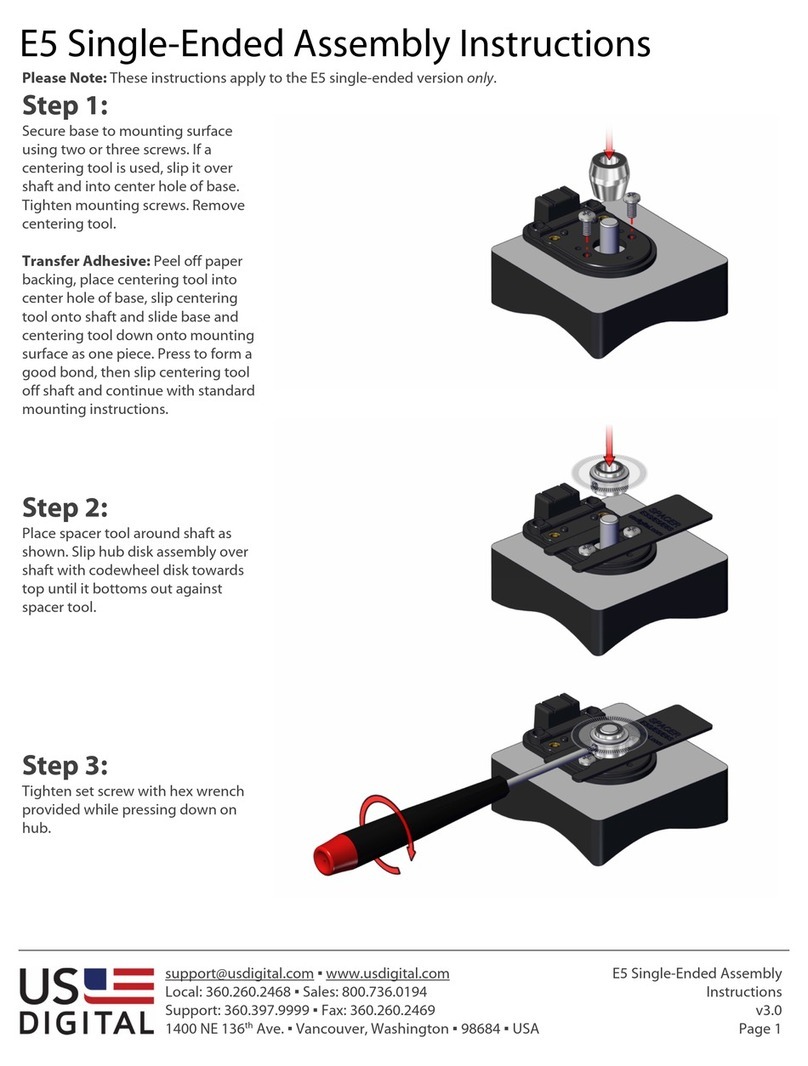

Mounting Screw Torque 2-3 in-lbs

Technical Bulletin TB1001 - Shaft and Bore Tolerances Download

(1) 60000 RPM is the maximum rpm due to mechanical considerations. The maximum RPM due to the module's 100kHz maximum

output frequency is (6000000/CPR).

(2) Including axial play.

Single-ended Electrical

Specifications Min. Typ. Max. Units Notes

E4T Miniature Optical Kit Encoder

Page 3 of 6

Rev. 20181113012651