1. GENERAL

The disinfection of potable water, swimming pool water and industrial water is usually

achieved by the addition of either chlorine, chlorine dioxide, sodium hypochlorite,

anorganic chlorine compounds or in combination with ozone.

It is very important to dose these disinfectants properly in order to achieve the correct

residual. An insufficient residual of the disinfectant may result in poor disinfection,

whereas an excessive residual may affect the taste of the water unfavourably or cause

corrosion in the water lines.

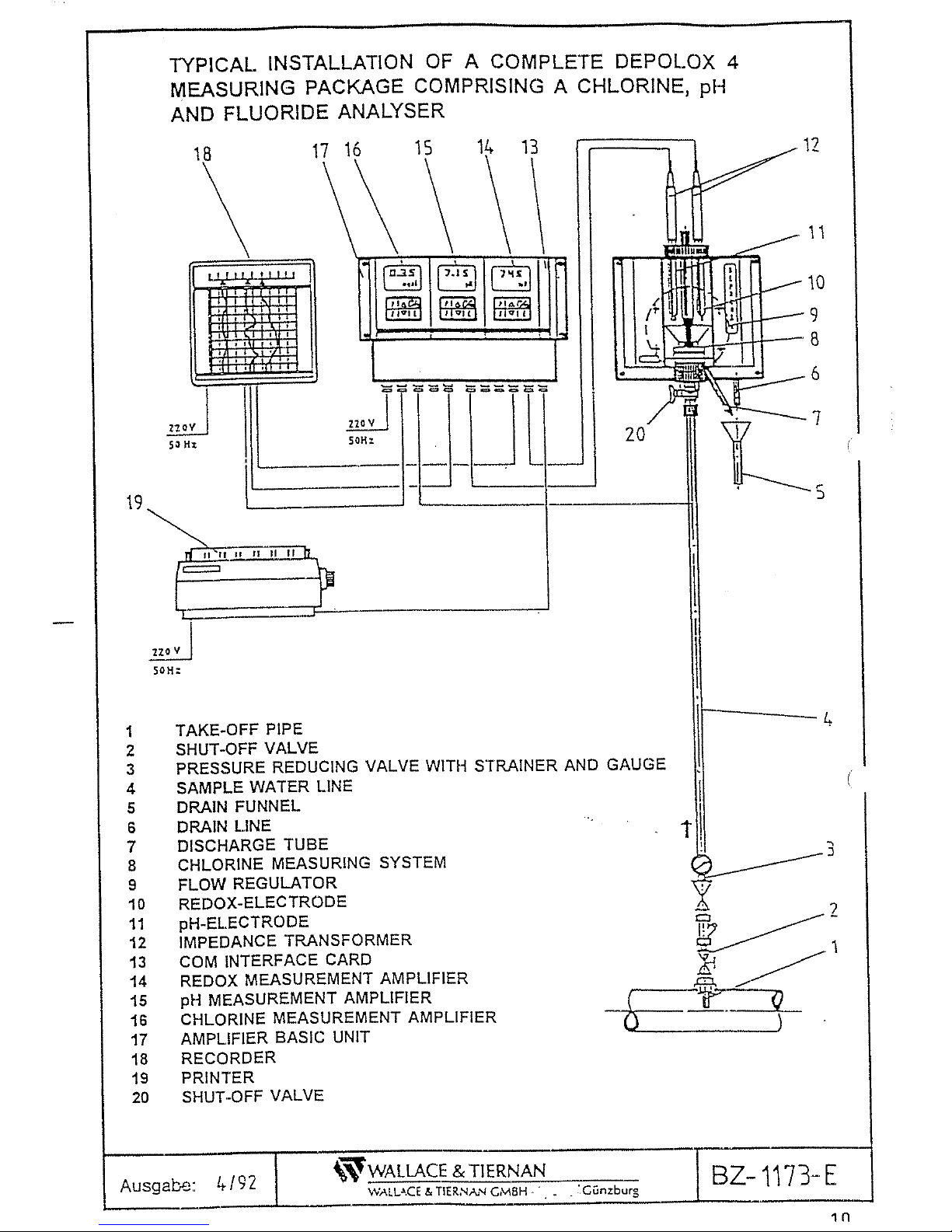

The DEPOLOX 4 residual analyser may be used for the continuous measurement of

disinfectant residuals such as chlorine, chlorine dioxide or ozone.

With additional equipment the dosage of these disinfectants may be controlled and

recorded.

The unit may also be used to check water which must not contain any disinfectants

(e.g. to check that no ozone is present after the water has passed through a

dechlorination filter).

2. DISINFECTANTS IN WATER - LIMIT VALUES

2.1 CHLORINE (Cl2)

According to current German regulations, potable water must not contain more than

0.3mg/l of effective chlorine. This amount may be increased temporarily up to 0.6mg/l

if required for sufficient disinfection.

A further requirement is that potable water (and water used by the food processing

industry) disinfected with chlorine shall contain at least 0.1 mg/l of free chlorine after

chlorination.

Processed swimming pool water (after flocculation, filtering and chlorination) is required

to contain 0.3...0.6 mg/l of free chlorine in every part of the swimming pool. The water

leaving the pool shall contain at least 0.3 mg/l of free and effective chlorine. If a

treatment with ozone is included in the process, the content of free chlorine in the water

shall be 0.2...0.5 mg/l.

NOTE!

The presence of chlorisocyanurates (chlorine stabilisers) will strongly impair the

measurement of chlorine residual. These chemicals, available in the form of

granules or pills, are not approved for use in swimming pool water and must not

be used in chlorine residual controlled systems.

8