9

English

!WARNING

Do not push down on the purge button in low temperatures, as this may cause a

second stage freeze-up.

• Closethecylindervalveandcheckthepressuregaugeonceagain.Duringtherst

minutethedisplayedpressureshouldnotdecrease.Thenopenthevalveagain.

• Ifthecylindervalveisequippedwithareserverod,verifythatitisfreetomove

downwardsforitsentirelength.Ifyouplanonusingthereserve,ensurethatthe

mechanicalreservevalveisinthecorrectposition(Up).

• CheckthattheentireSCUBAunitisfunctioningcorrectlybyperformingseveral

completebreathingcycles(deepinhalation/exhalation)withthecylindervalveopenand

thesecondstagemouthpieceinthemouth.

• CheckthatalldevicesconnectedtotheSCUBAunitareoperatingcorrectly.For

example,checkthatthebuoyancycompensatorinator(orthedrysuitinletvalve)is

functioningetc.

!WARNING

Never connect a low pressure hose to a high pressure port. These connection

threads are different sizes and are not compatible. Do not use adapters of any

kind to connect low-pressure devices to high-pressure ports. Doing so could cause

serious damage to both the user and equipment.

!WARNING

Do not attach a L.P. hose to a Scuba regulator high pressure (HP) port or to an air

supply with pressure in excess of 200 psi (13.8 bar). This may result in damage or

explosive failure of the Ination Valve or Low pressure Hose, which could result in

injury or death.

6. EQUIPMENT USE

CheckthattheSCUBAunitiscompleteinallrespectsandcomplieswithallrequirements.

Refer to the IMPORTANT WARNING REMINDERS and PREPARING FOR USE sections

and the regulators and BC manual. Open the cylinder valve, don the equipment en put

thesecondstageinyourmouth,breathedeeplyafewtimestoensurethatthesystemis

operatingcorrectly.Whenthemouthpieceisoutofthemouth,simplypressingthepurge

buttonmaytriggertheVenturieffectandcausearegulatorfree-ow.Thefree-owcanbe

stoppedbycoveringthemouthpieceopeningwithanger.

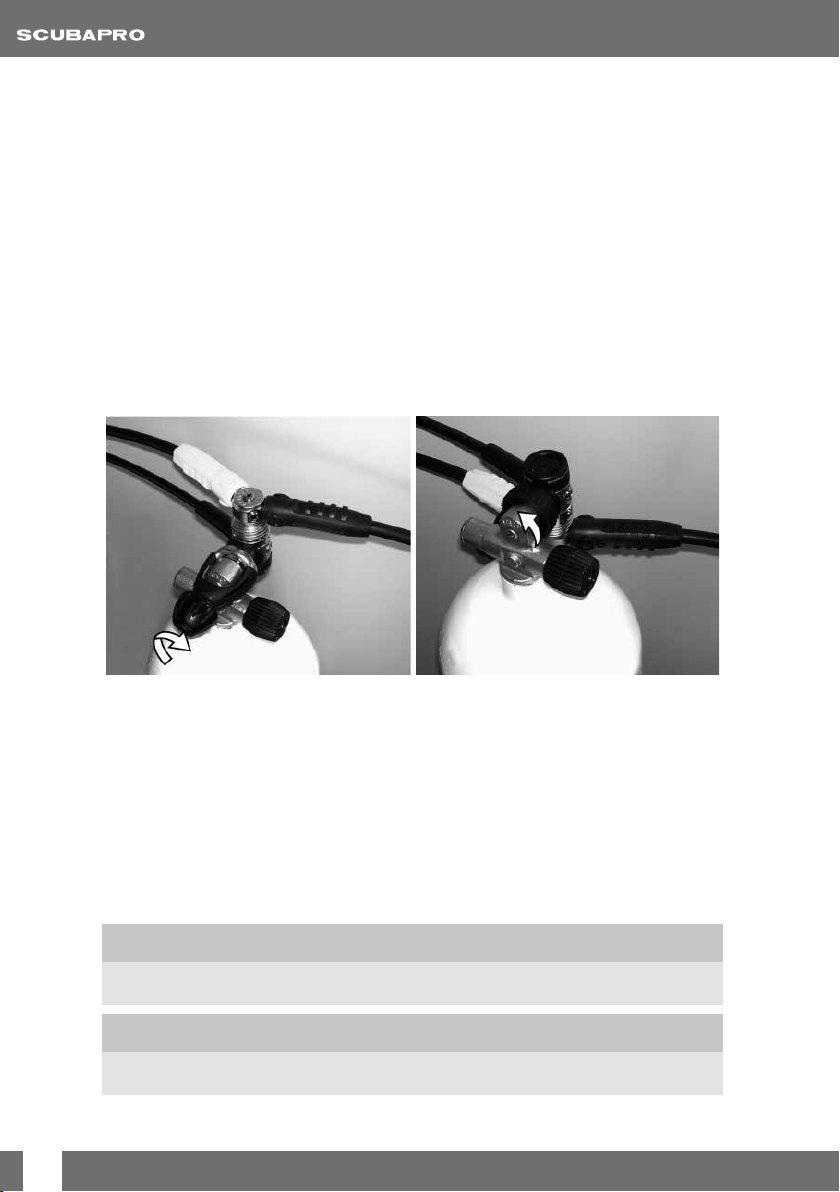

6.1 InatoruseoftheAIR2(normaloperatingmode)

WhenproperlyinstalledontheleftshoulderoftheBC,theAIR2canbefullyoperatedwith

thelefthandbypushingthebuttonsforination(P)ordeation(O)(seeimg3).Thesetwo

buttonsareoffsetandshowdifferentsizesforeasyidentication.Thesmallerbutton(P)is

depressedforautomaticination.Thelargerbutton(O)isdepressedfordeation.Fororal

ination,only thelarge deationbutton isused. Toinate, thediver sealshis lipson the

mouthpiece, fully depresses the deation button, then exhales into the mouthpiece and

releasesthebuttontocapturetheexhaledair.

TheAIR2hasaspecicquickconnection(C)tothelowpressurehosewhichallowsfast

connectionanddisconnectionevenwhenthesystemisalreadypressurized.Thesystem

automaticallystopstheairowfromthehoseonceit’sdisconnectedfromtheAIR2using

thequickcoupling.(img3)