GENERAL

Carefully read the following important information regarding

installation safety and maintenance.

Keep this information booklet accessible for further consulta-

tions.The appliance has been designed for use in the ducting

version (air exhaust to the outside – Fig.1B), ltering version

(air circulation on the inside – Fig.1A) or with external mo-

tor (Fig.1C).

SAFETY PRECAUTION

1. Take care when the cooker hood is operating simultane-

ously with an open replace or burner that depend on the air

in the environment and are supplied by other than electrical

energy, as the cooker hood removes the air from the environ-

ment which a burner or replace need for combustion.

The negative pressure in the environment must not exceed

4Pa (4 x 10-5 bar).

Provide adequate ventilation in the environment for a safe

operation of the cooker hood. Follow the local laws applicable

for external air evacuation.

Before connecting the model to the electricity network:

-Control the data plate (positioned inside the appliance)

to ascertain that the voltage and power correspond to the

network and the socket is suitable. If in doubt ask a qualied

electrician.

-If the power supply cable is damaged, it must be replaced

with another cable or a special assembly, which may be

obtained direct from the manufacturer or from the Technical

Assistance Centre.

2. Warning!

In certain circumstances electrical appliances may be a

danger hazard.

A)Do not check the status of the lters while the cooker

hood is operating.

B)Do not touch bulbs or adjacent areas, during or straight

after prolonged use of the lighting installation.

C)Flambè cooking is prohibited underneath the cooker

hood.

D)Avoid free ame, as it is damaging for the lters and a

re hazard.

E) Constantly check food frying to avoid that the over-

heated oil may become a re hazard.

F) Disconnect the electrical plug prior to any maintenance.

G)This appliance is not intended for use by young children

or inrm persons without supervision.

H) Young children should be supervised to ensure they do

not play with the appliance

I) There shall be adequate ventilation of the room when

the rangehood is used at the same time as appliances

burning gas or other fuels.

L) There is a risk of re if cleaning is not carried out in

accordance with the instructions.

This appliance conforms to the European Directive EC/2002/96,

Waste Electrical and Electronic Equipment (WEEE).

By making sure that this appliance is disposed of in a suitable

manner, the user is helping to prevent potential damage to

the environment or to public health.

The symbol on the product or on the accompanying

paperwork indicates that the appliance should not be

treated as domestic waste, but should be delivered to

a suitable electric and electronic appliance recycling

collection point. Follow local guidelines when disposing of

waste. For more information on the treatment, re-use and

recycling of this product, please contact your local authority,

domestic waste collection service or the shop where the ap-

pliance was purchased.

INSTALLATION INSTRUCTIONS

Assembly and electrical connections must be carried out

by specialised personnel.

•ElectricConnection:

This is a class I, appliance and must therefore be connected

to an eecient earthing system.

-The appliance must be connected to the electricity supply

as follows:

BROWN = Lline

BLUE = Nneutral

YELLOW/GREEN = earth.

The neutral wire must be connected to the terminal with the

N symbol while the YELLOW/GREEN, wire must be connected

to the terminal by the earth symbol .

When connecting the appliance to the electricity supply,

make sure that the mains socket has an earth connection.

After tting the ducted cooker hood, make sure that the

electrical plug is in a position where it can be accessed easily.

If the appliance is connected directly to the electricity sup-

ply, an omnipolar switch with a minimum contact opening

of 3 mm must be placed in between the two; its size must

be suitable for the load required and it must comply with

current legislation.

• The minimum distance between the support surfaces of

the cooking pots on the cooker top and the lowest part of

the cooker hood must be at least 65 cm. If a connection

tube composed of two parts is used, the upper part must be

placed outside the lower part. Do not connect the cooker

hood exhaust to the same conductor used to circulate hot air

or for evacuating fumes from other appliances generated by

other than an electrical source. Before proceeding with the

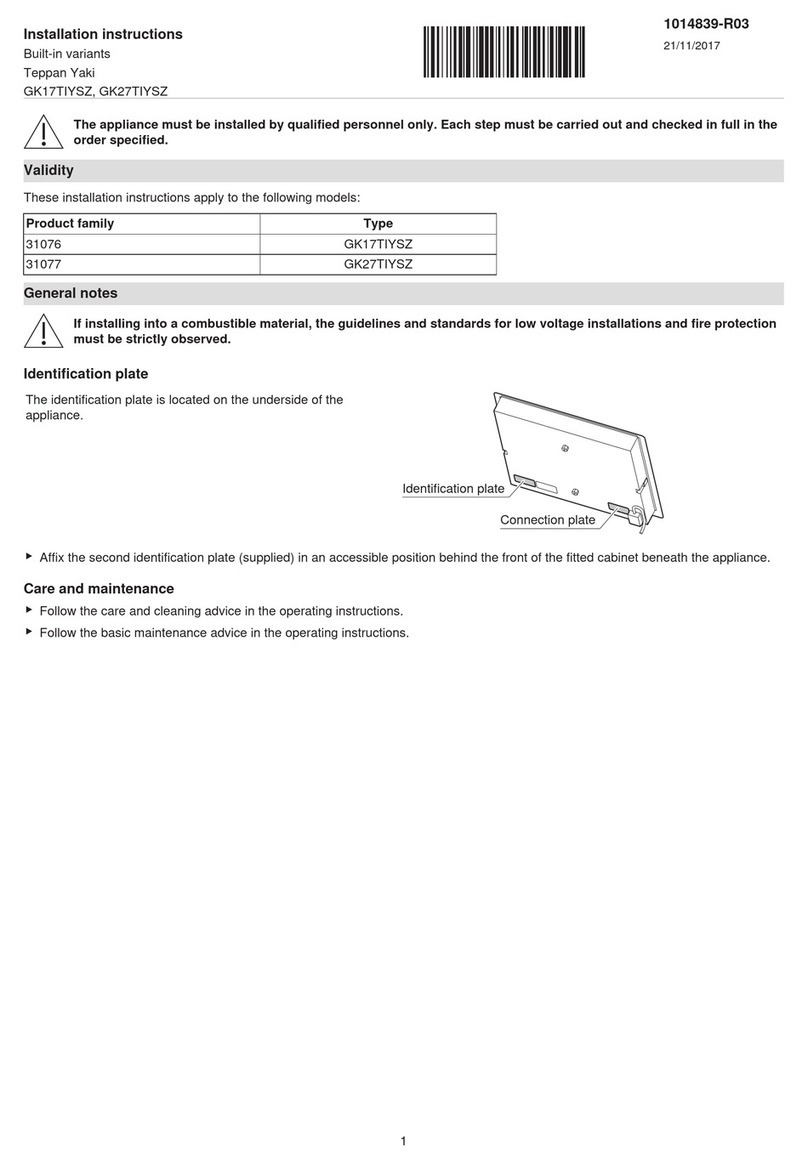

assembly operations, remove the anti-grease lter(s) (Fig.15)

so that the unit is easier to handle.

• We recommend the use of an air exhaust tube which has the

same diameter as the air exhaust outlet hole. If a pipe with

a smaller diameter is used, the eciency of the product may

be reduced and its operation may become noisier.

In the case of assembly of the appliance in the suction version

prepare the hole for evacuation of the air.

Attention!

- Before installing the appliance, x the electrical box D.

- Lift the electrical box and follow phases 1-2-3 indicated in

gure 2.

- Position the bracket in correspondence with the 3 screws G

already set up on the container and screw them is indicated

in phase 4 - gure 2.

- Fix the air exhaust pipe H(not included) on the air outlet

ENGLISH EN

- 19 -