Now for the Warnings!

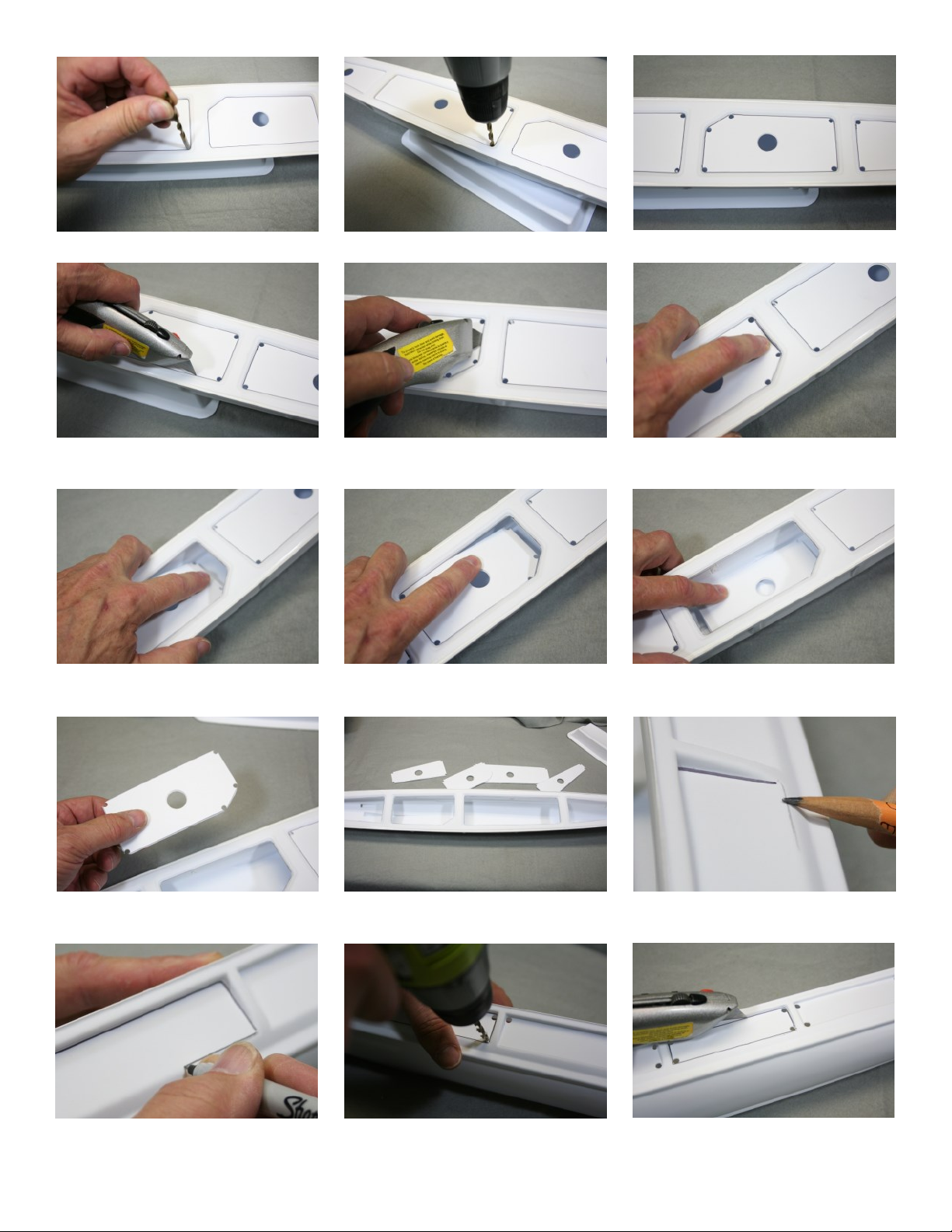

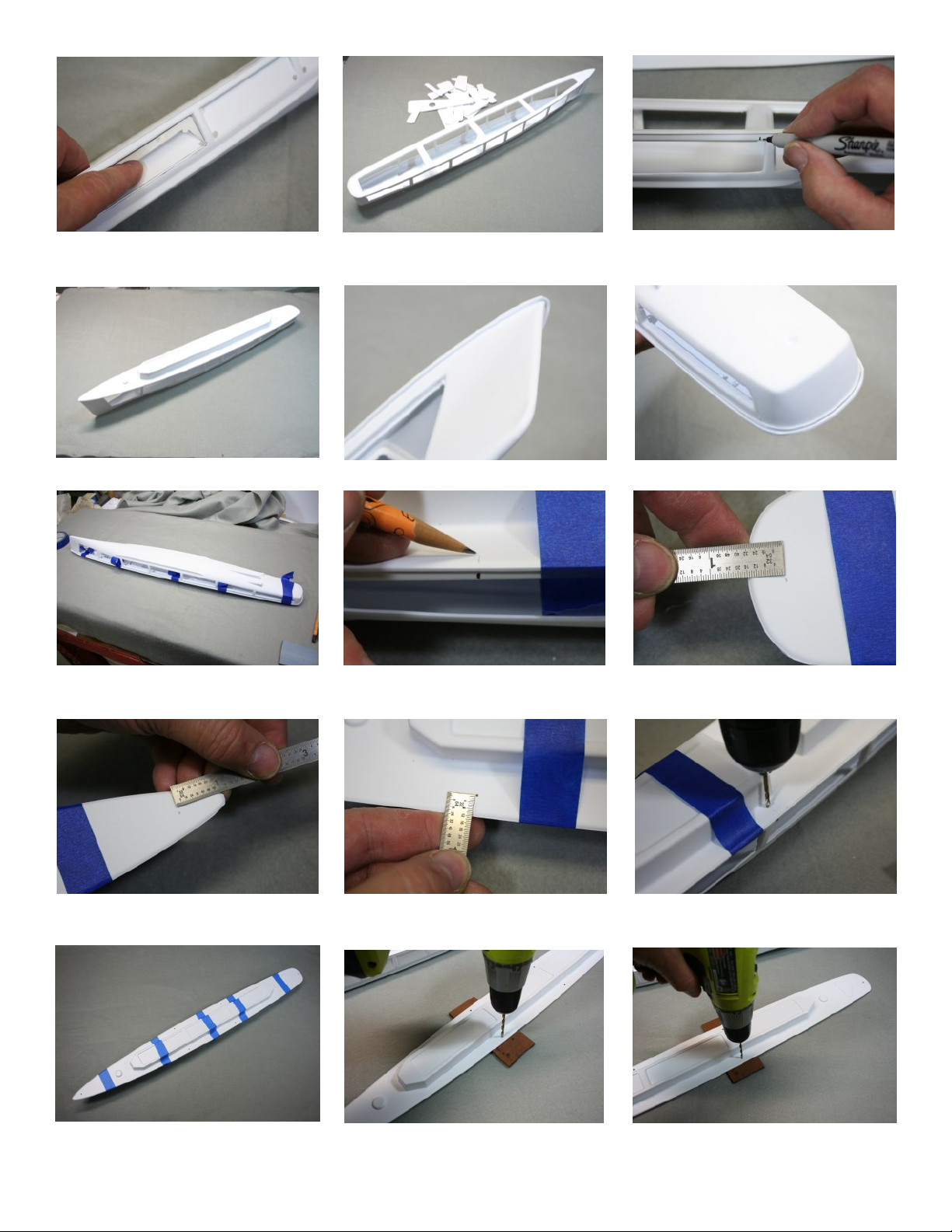

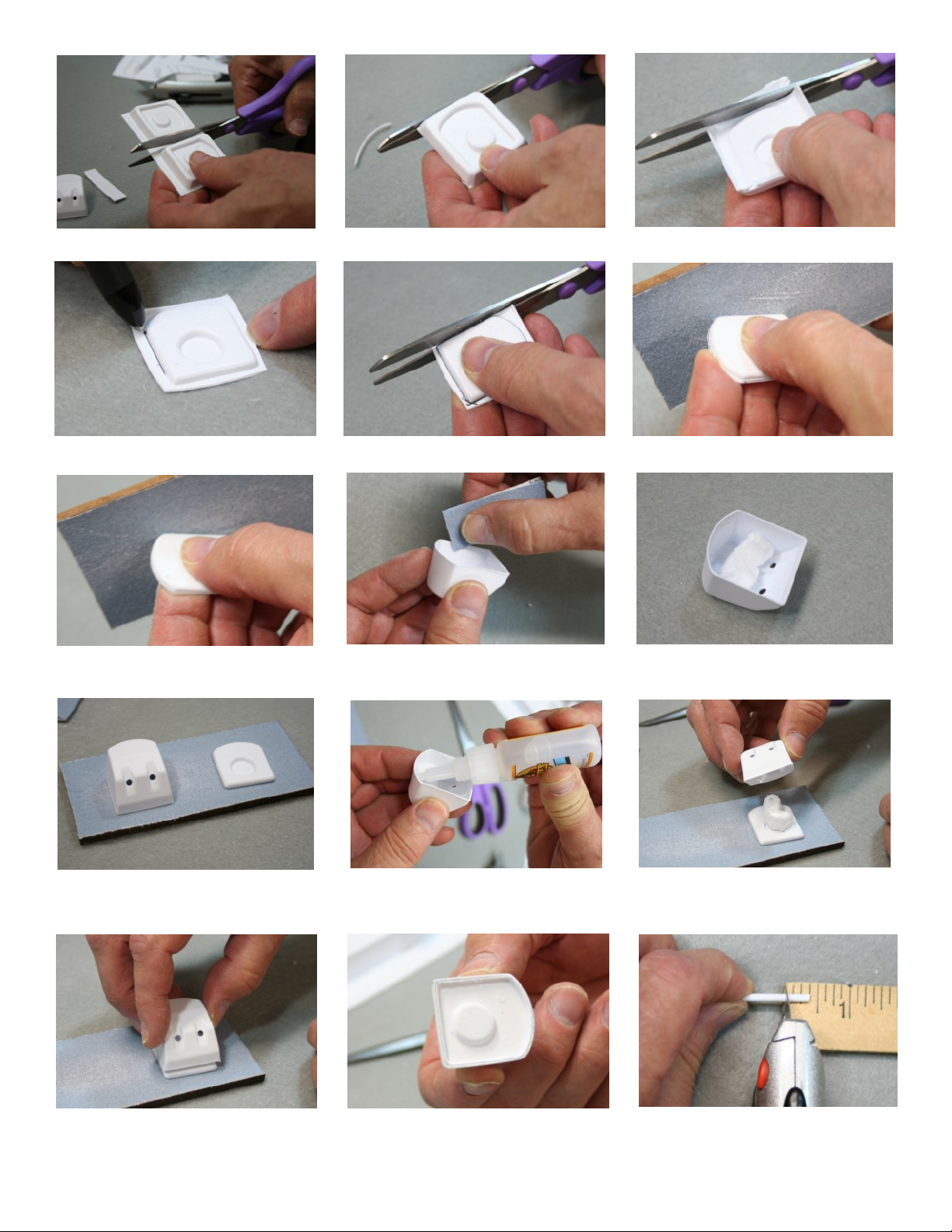

Read all of the instructions! Review and understand each step, and the one after, as you build

your boat. Don’t rush. Good work takes time.

This is not a toy! I know. It LOOKS like a toy, but it isn’t. Toys are generally safe for small

children. This boat is not safe for small children. Assembling it requires the use of sharp tools

that can cut skin, strong adhesives than can bond flesh and injure eyes, spray paints that can be

flammable and toxic, as well as batteries that can short causing severe burns or fires. Read all of

the instructions and warnings on all of the tools and chemicals you plan to use. Use protective

eyewear when recommended. USE SAFETY GLASSES! If you think you don’t have the

skills, or are uncomfortable with tools and chemicals, or just changed your mind, then pack

up this kit and return it immediately for a full refund including economical standard return

shipping. If you need some help, find a local boat club to join, check with the hobby shop

where you purchased your radio gear, or contact local RC Warship Combat clubs and

organizations for assistance. Keep your work area away from children. Even if you have no

children, when not working on the kit, keep all sharp objects and all chemicals locked away in a

safe area. You never know who will come to visit and how well they will supervise the young

ones with them.

This is STILL not a toy! Once you complete the boat and are running it in a lake, know that the

boat can injure life, limb, and property. Never touch the propeller, spinning or not, while there is

a battery inside or connected to the boat. Even if it is turned OFF, assume it can glitch and run on

its own. Never run the boat if swimmers are in the water. Don’t chase wildlife. Be careful with

rechargeable batteries. They have the ability to dump large amounts of current in a very brief

period of time if shorted, causing burns or fires. Never store the boat with the battery inside it,

connected or not. Keep your batteries in a safe place, out of the reach of children. You are

responsible for the safe use of this product. You are responsible for choosing wisely, those who

you entrust the use of the boat and radio, even for a few minutes at a lake.

Never swim after a disabled model boat!

All of these warnings are just for the Hull Kit! Add the RC Warship Combat parts and this

model is ABSOLUTELY DANGEROUS. Use safety clips in the cannon when not battling to

prevent accidental firing of a bb. Know that Lithium batteries are dangerous if mishandled,

damaged or if charged improperly. CO2 powered firing systems contain pressurized gas

that can project parts at a high rate of speed during assembly or repair. Everyone wears

SAFETY GOGGLES when in combat, repairing or testing on the work bench.

WARNING

CHOKING HAZARD - Small parts. Not for children under 3 years.

WARNING - To avoid danger of suffocation, keep plastic bags away from babies and children. Do not use in

cribs, beds, carriages or play pens.

WARNING: Brass parts in this kit contain lead, a chemical known to the State of California to cause cancer

and birth defects and other reproductive harm.

WARNING: THIS IS NOT A TOY! Once completed, this model should only to be used with the Safety

Rules and guidelines of the International Radio Controlled Warship Combat Club

http://ircwcc.com/main/home/rules/ 2