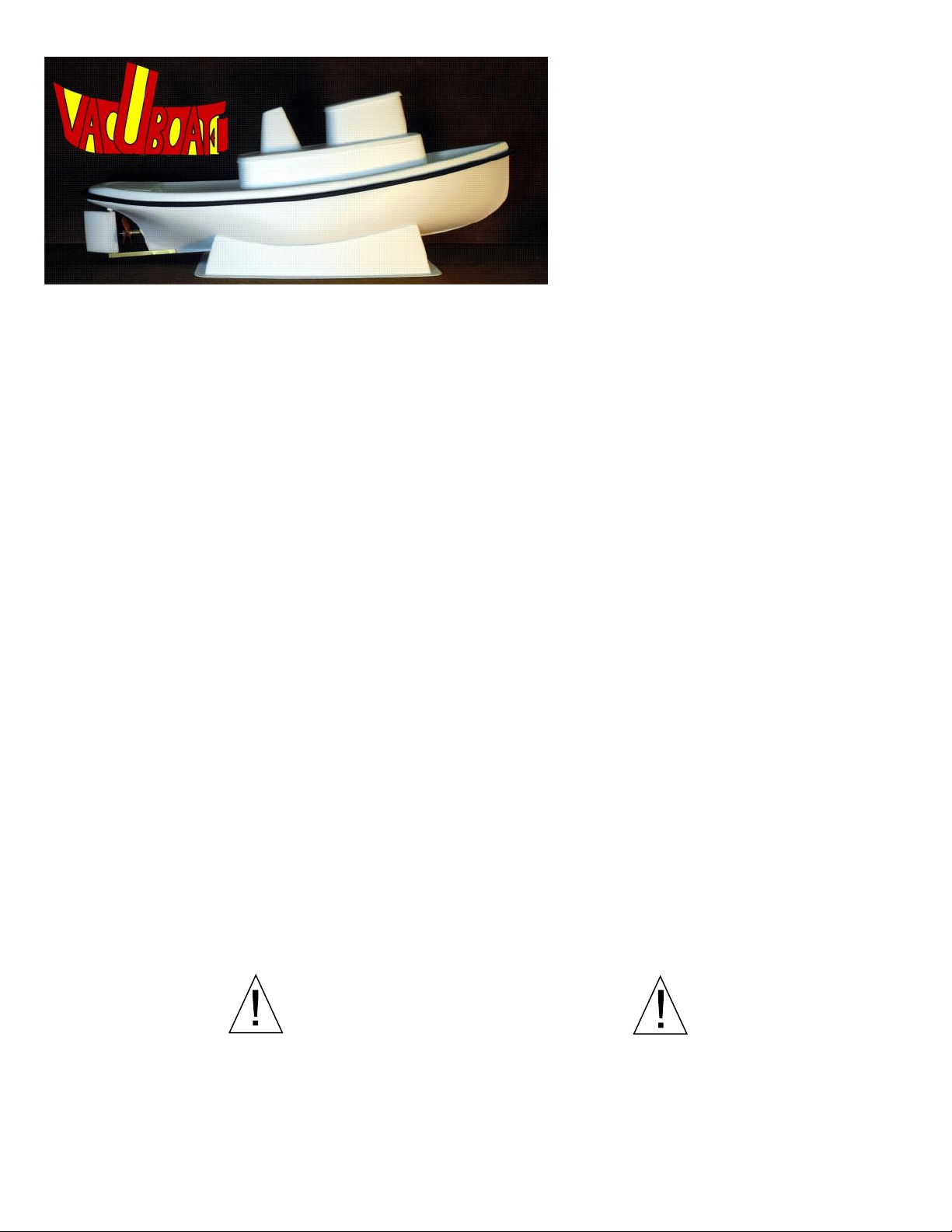

WARRANTY AND RETURN POLICY: All Vac-U-Boat Hull Kits are sold direct from Vac-U-Boat. If you

purchased this from a dealer, contact that dealer on any matter of return. If you open and inspect this kit and for

any reason you do not wish to keep it, return all of the parts to their bags and repack the kit into it’s box along

with a copy of the receipt. (Keep an original for your records.) Mail to Vac-U-Boat via the United States Post

Office, Parcel Post with tracking. Please do not use any Express Mail carrier or send COD. Upon receipt of the

complete kit, I will reimburse you the original cost plus the cost of the return postage shown on the package and

mail those funds to the name and address on the receipt copy. I will replace any defective part found during the

assembly or operation of the boat for a period of three months after the purchase date. This warranty does not

cover damage caused by abuse, misuse, improper spray paints, alteration or accident. It does not cover

consequential damages. You may have other rights, which vary from state to state. Caution: Never leave the

boat in a hot car. It will melt!

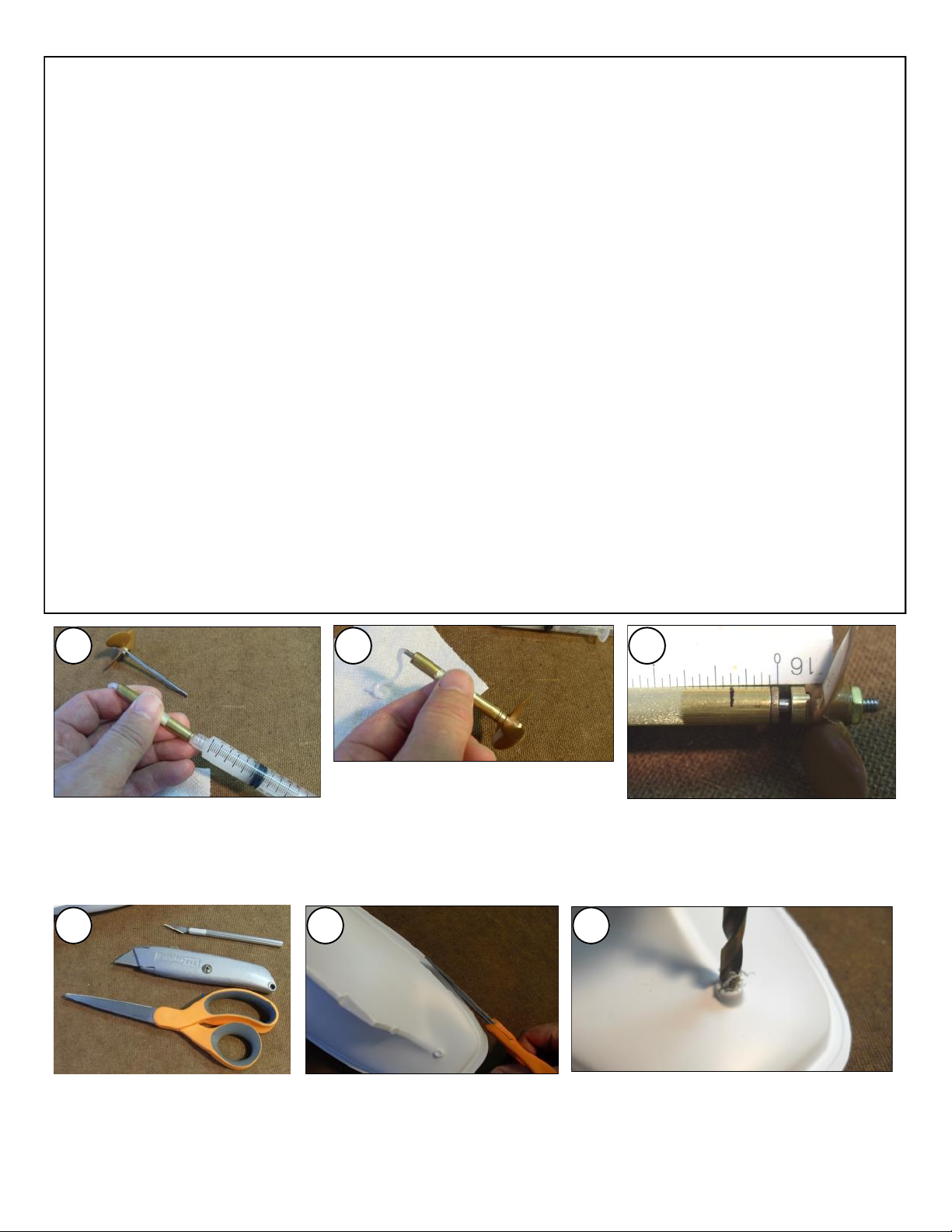

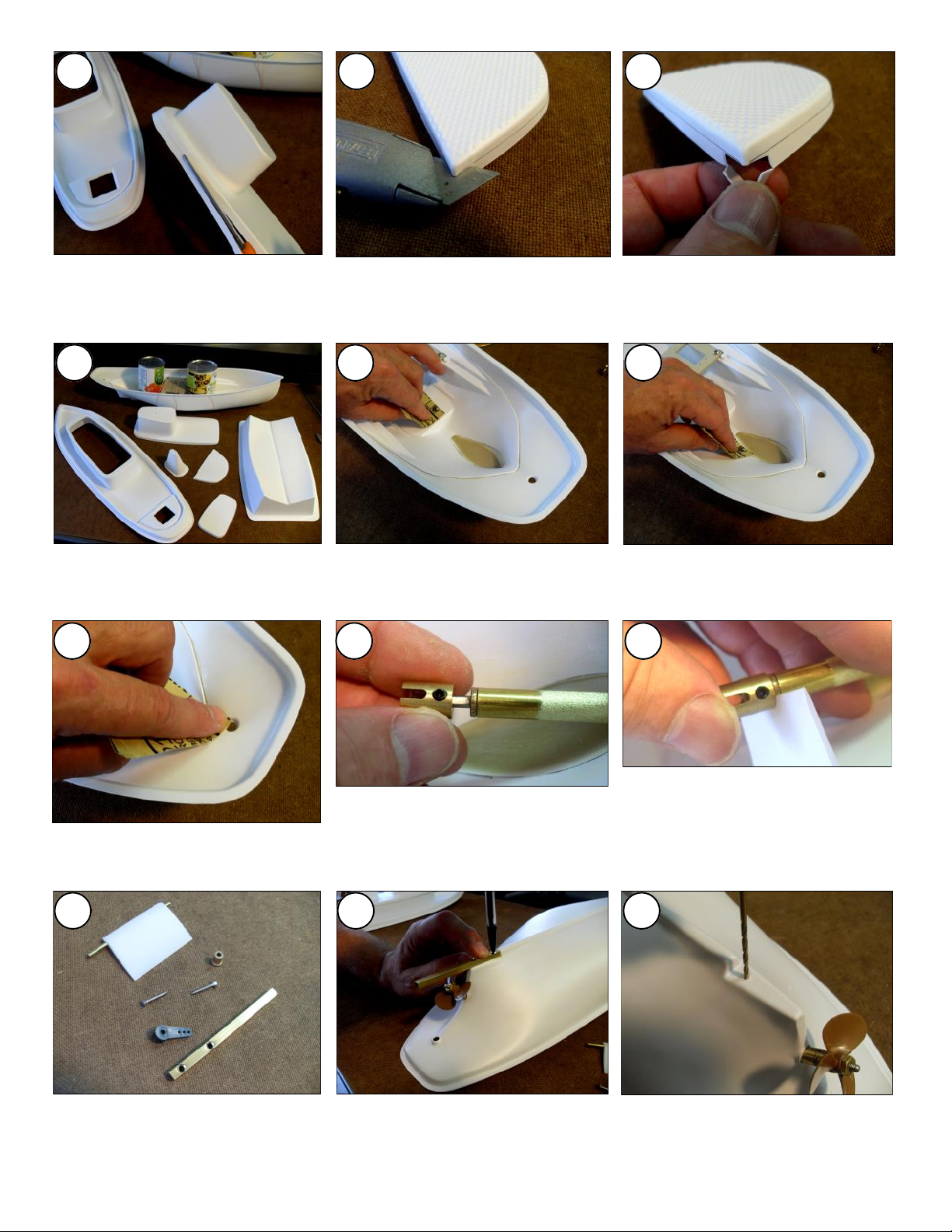

CUTTING PLASTIC: Adults only! A sharp pair of sewing scissors is best to trim around the parts. Cut through

sharp corners in the plastic with a hobby knife. While H.I.P.S. is tough, it will tear. When cutting out holes, as in

the top of the Cabin and through the rear hatch, score the opening with the tip of the hobby knife. (Just a deep

scratch.) Then trace the score 2 or 3 more times and you will cut through the plastic. As you cut through the

plastic, hold the knife at a side-angle to keep the blade from binding in the cut. Don’t hurry. Draw the blade

slowly along the plastic to prevent overcutting. Think about where the blade would go if it slipped. (Like, into

your leg or arm!)

GLUE: You will need about two ounces of 30-Minute or “2-Ton” epoxy. Most 15-Minute or shorter-time

epoxies will break down over time with exposure to water. 30-Minute is waterproof and gives you more working-

time for this model. Epoxy is used for the rudder shaft, skeg reinforcement, rudder bearing & ballast weights.

Where specified, a filler should be added to make the epoxy less brittle, increase the volume, and to thicken it.

Dry plaster, talcum powder, or micro-spheres all work well. Mix the two parts of the epoxy together first. Then,

add the same volume of filler material and fold them together until blended. Medium CA (super glue) is best for

gluing the H.I.P.S. together when attaching the Hull to the Deck, the Pilot House Roof to the Pilot House and for

the Stack to the Deck. “Gorilla” brand Super Glue has a “medium” consistency and works well. If you are

inexperienced with CA Glue, those small metal tubes of Model Cement found where plastic model cars are sold,

either the regular kind or the “non toxic” type will work. Model cars are made of the same type of plastic as this

boat. However, because the sheet plastic is so thin, it will melt more easily if you use too much glue. CA provides

the strongest seam with less chance of weakening or melting the plastic but must be used in a well ventilated area.

Both CA and Model Cement are permanent. If you think you will ever want to separate the upper and lower hulls,

then glue them with epoxy. You will have to scuff the surfaces of plastic to help the epoxy bond to the plastic.

Gentle prying will separate the parts. Experiment with the glues using the scrap of plastic you cut from the top of

the deck. This scrap can be used for testing glues or paints. Glue them together and then try to tear them apart.

Sandpaper, rubber bands, clamps and other tools are included to help with assembly.

PAINT: Use spray paints that are labeled as safe for plastics. The short cans of “Hobby Enamel” found at your

hobby store, or spray paints safe for plastics like Krylon Fusion or Plasticote brands work best. When buying

them, if the lid isn’t sealed, remove the cap to see if someone “test sprayed” the can. If it has any paint residue on

the spray nozzle, don’t buy it. It is likely clogged because it was not properly cleared by inverting the can and

spraying the paint out of the nozzle. (See the can’s directions.) No sanding is necessary. Hobby Enamels, Fusion,

and Plasticote will bond with the H.I.P.S. well as long as the plastic is clean. Don’t get grease or oil on the plastic

as it can repel the paint. If in doubt, wash your hands with liquid detergent before handling the plastic. Buy a can

of Clear Hobby Enamel or Clear Krylon Fusion when you are getting the colors. It makes a great top coat on dull

metallic or dark colors that don’t gloss on their own. Test the colors on the scrap to see if a coat of clear is

necessary. NEVER USE LACQUER OR AUTOMOTIVE PAINTS ON H.I.P.S. PLASTIC. It will soften the

plastic and greatly shorten its life span and may completely melt the plastic. Avoid all tall spray cans like Krylon®

or other “household enamels”. They will damage the thinner areas of the sheet plastic. Don’t be fooled by test

spraying auto paint onto the scrap. They are thicker than the model parts and will be less affected. Avoid the short

cans of lacquer you will find at hobby stores. Ask for hobby enamel. I have listed additional painting tips at the

end of the manual.

2