page 3 of 17

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999001 / 04/04/2012

Contents

Safety information! .....................................................................................................4

General information............................................................................................................................4

Intended use.......................................................................................................................................4

Connecting the device .......................................................................................................................4

Operating conditions .........................................................................................................................5

Safety during operation .....................................................................................................................5

Maintenance and repair .....................................................................................................................5

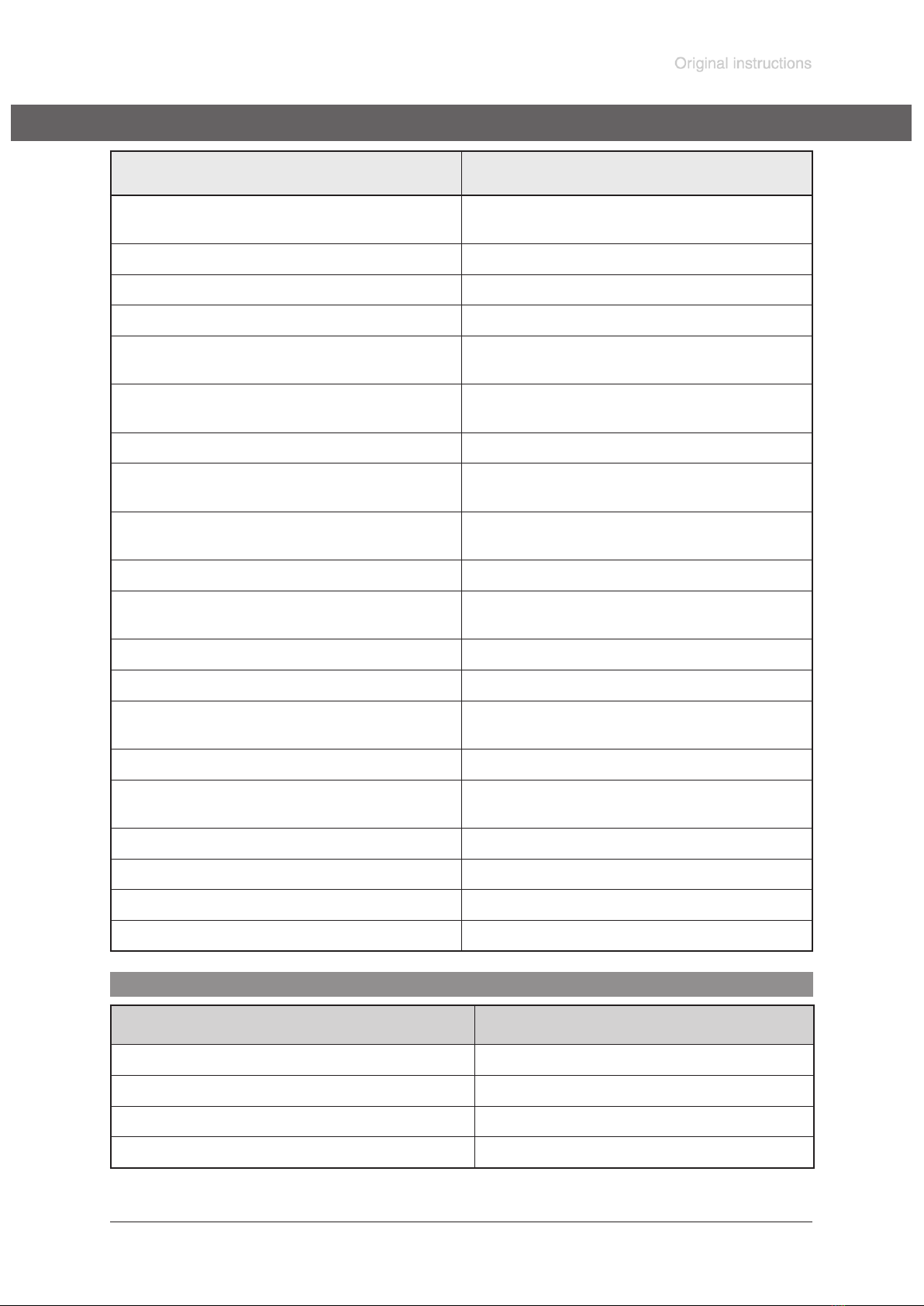

Technical data .............................................................................................................7

Wetted parts ......................................................................................................................................7

Use and operation ......................................................................................................8

Changing the pressure unit ...............................................................................................................8

Pressure measurement .....................................................................................................................9

Clock symbol .....................................................................................................................................9

Adjusting the operating time and the measuring cycle ......................................................................9

Display of the battery‘s discharge status.........................................................................................10

Troubleshooting .......................................................................................................10

Readjustment of the vacuum gauge DVR 2 ...........................................................11

Adjustment at atmospheric pressure ............................................................................................... 11

Adjustment under vacuum............................................................................................................... 11

Adjustment to a reference pressure ................................................................................................12

Calibration in the factory .........................................................................................12

Replacing the battery ...............................................................................................13

Notes on return to the factory .................................................................................14

Health and safety clearance form ...........................................................................15

EC Declaration of Conformity .................................................................................16

➨DANGER indicates a hazardous situation which, if not avoided, will re-

sult in death or serious injury.

☞WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

• CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

Note: The device contains a battery!

Remove battery before disposal (see section ”Replacing the bat-

tery”) and dispose of battery and device separately and according

to regulations.

NOTICE