RC series OPERATION

DO NOT USE UNSAFE EQUIPMENT

Perform all the daily checks in the maintenance section

before starting the engine. See Daily Maintenance Checks

in the full Operations Manual.

Do not operate a vacuum lifting system with unapproved or

missing parts, or if it is damaged or malfunctioning. Correct

any problems before operating equipment.

NOTE: Do not make alterations or modifications to the lifter.

Always inspect the lifting pad and pad seal for any damage

prior to each shift.

KEEP PERSONNEL AWAY

Keep personnel a safe distance away from the load and

excavator when lifting.r objects.

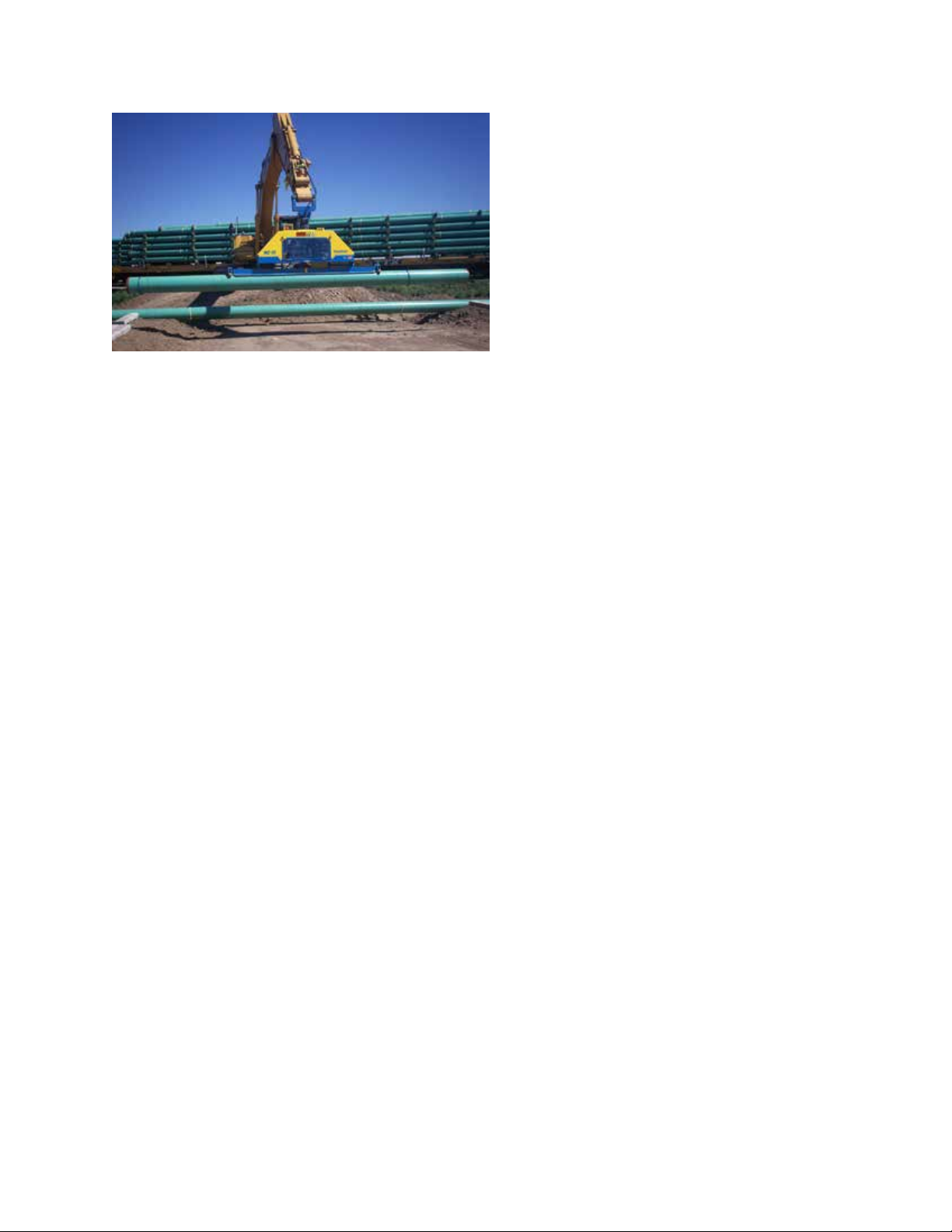

PROPERLY POSITION THE VACUUM PAD

Do not operate until the vacuum pad is properly positioned

on the pipe. Place lifter slowly onto pipe. This will allow the

guide wheels to locate the pad properly on the pipe. The

guide wheels will help align the vacuum pad on the pipe.

LIFT, LOWER, AND ROTATE SLOWLY

Always lift the load slowly. Make sure the area is clear when

moving the pipe. All bystanders must be kept at a safe

distance. Rotate the pipe slowly, and carefully lower it

into position.

Never release the vacuum while the load is being lifted.

Make sure the pipe is properly supported before releasing

the vacuum.

KEEP LOADS LOW

Do not lift loads higher than necessary. Always keep loads

close to the ground when possible. Never leave a suspended

load unattended. Always lower the load to the ground when

not in use. Never attempt to lift pipe with rope around it.

You will not be able to get the proper vacuum to safely lift.

Remove the rope or reposition the pad away from the rope.

LIFT PIPE NEAR CENTER

Lift the pipe as close to the center as possible to keep the

load balanced. Marking the center of the pipe before lifting

is safe and more efficient, and can speed up the operation.

2. Keep this setting before adjusting the valves again. The

more the valves are open, the faster the rotation speed

will be.

3. Geographical and environmental conditions, the size of

the excavator and the load being lifted will all affect

the rotation speed. Always start out slow and gradually

increase the rotation speed.

Do not exceed 26 GPM (98.4 LPM) or 3600 psi (248.2 bar).

Exceeding 26 GPM (98.4 LPM) or 3600 psi (248.2 bar) may

damage rotator and void your warranty.

ROTATE THE LIFTER

1. Make sure the area is clear of any bystanders or

obstacles.

2. Slowly rotate the vacuum lifting system in each

direction for a recommended minimum of 30 rotations.

This will bleed the air out of the hydraulic system so it

can be rotated smoothly and safely. Never operate at

full pressure.

HYDRAULIC SERIES

On fully hydraulic models there are 2 additional hoses to run

the motor.

1. Connect these 2 hoses (without flow control valves)

to the auxiliary lines.

2. Set excavator controls to 1-way or hammer mode.

AUXILIARY HYDRAULICS

For the auxiliary hydraulics running the drive, recommended

operating pressure is 3000 psi/20.68 MPA. Pump capacity

should be 10.6 to 23.8 GPM.

OPERATION

OPERATING TIPS

The following information does not include all conditions that

may be encountered in standard operations, but is intended

to supplement any operational and safety training (which is

the responsibility of the owner or contractor). Contact your

Vacuworx representative for additional training information.

Before operating this equipment, read the entire Operator’s

Manual and become familiar with the operating controls and

their functions.