Head Office:

VAISALA Oy

PL 26, FIN-00421 Helsinki

FINLAND

Phone (int.): (+358 0) 894 91

Telefax: (+358 0) 894 9227

Telex: 122832 vsala fi

SO 9001

CERTIFIED

QUALITY

SYSTEM

MAINTENANCE AND REPAIR

Ball earings must e checked once a year visually and y rotating

the sensor shaft. To do this, remove the cup wheel. The shaft should

spin smoothly and should not create any detecta le noise.

Replacement should e done only y a trained technician, as fol-

lows:

1Loosen and carefully remove the hexagon screw of the

cup wheel, not ending the connector pins on top of the

shaft.

2Loosen the hex nut of the connector (with 22 mm tool).

3Loosen the three screws at the ottom of the sensor ody

(with 7 mm tool).

4Remove the ody cover; handle carefully the O-rings.

5Release the three wires from the screw terminals on the

lower circuit oard.

6Loosen the three nuts at the ottom of the circuit oard.

7Remove the lower circuit oard.

8Loosen the spacer screws (with 6 mm tool); carefully, not

ending.

9Remove the upper circuit oard.

10 Loosen the hexagon screw of the rotating transformer

assem ly and remove it.

11 Remove the retaining ring at the shaft tunnel (using

narrow-pointed pliers).

12 Remove the upper earing after pulling out the shaft.

13 Remove the retaining ring at the shaft (using narrow-

pointed pliers).

14 Remove the lower earing.

Be careful when handling the ball bearings!

Reverse work order for assem ling the sensor.

NOTE for reassem ly! At step 10, the rotating transformer is in-

stalled ut its fixing screw is not fastened until the lower circuit

oard is installed and fixed (steps 7, 6). After that, to adjust the air

gap etween the transformer coils, first push the transformer (10)

as far up as possi le. The ferrite coils are breakable, do NOT

prise them ith any hard tool. Then place a screwdriver tip into

the slot etween part 10 and the shaft tu e, and pry until the air gap

underneath part 10 is 0.4 mm (0.016"). Finally, fasten the hexagon

fixing screw. Make sure the part 10 does not touch the trans-

former lo er part at any rotary position of the shaft.

The O-rings must be replaced by new ones before reassembling.

TECHNICAL DATA

Sensor/Transducer type Cup anemometer/ Opto-chopper

Measuring range 0.4 ... 75 m/s

Starting threshold < 0.5 m/s 1)

Distance constant 2.7 m

Transducer output 0...750 Hz square wave (for 0...75 m/s)

Characteristic Transfer Function Uf = 0.2425 + 0.09793 × R

(Uf = wind speed; R = o/p pulse rate)

Accuracy (within 0.4 ... 60 m/s)

with Characteristic Transfer Function ± 0.17 m/s 2)

with “simple transfer function” Uf = 0.1 × R –0.3/+1.0 m/s 3)

Transducer output level High state > 11 V (with Iout < +5 mA)

Low state < 1.5 V (with Iout > –5 mA)

Input power supply 24 VDC ± 10 %, max. 3.3 A

(max. 3.9 A with WAV151 added)

Power consumption 70 W elow +2 °C; 1 W a ove +5 °C

(typical, with Uin = 24 VDC)

Heating control Shaft heating on at < +5 °C (12 W)

Cup heating on at < +2 °C (49 W)

Temperature sensing With external 10 kohm NTC-resistor

included in the cross arm j- ox wiring

O/P power (for WAV151, WAT12 etc.) 13 VDC, 70 mA max.

24 VDC, 0.6 A (on at < +5 °C)

Electrical connections MIL-C-26482 type 6-pin plug;

6-wire ca le through cross arm tu ing

Operating temperature –55 ... +55 °C

Storage temperature –60 ... +70 °C

Housing material AlMgSi, grey/partially lack anodized

Cup material PC reinforced with glassfi re; lack

15 W foil heater integral in each cup

Dimensions & Weight 270 (h) × 90 (Ø) mm; weight 860 g

Swept radius of cupwheel: 91 mm

1) Measured with cup wheel in position least favored y flow direction.

Optimum position would yield < 0.35 m/s threshold.

2) Standard Deviation

3) Typical error vs. speed with the “simple transfer function” used :

Spare parts: Order number:

Cup wheel assem ly WA35066

Set of earings & gasket 16644WA

RANGE m/s 0-5 5-10 10-15 15-20 20-24 24-29 29-34 34-39 39-44 44-48 48-58

ERROR m/s -0.2 -0.1 0.0 +0.1 +0.2 +0.3 +0.4 +0.5 +0.6 +0.7 +0.85

Ref. WAA251-U186en-1.1

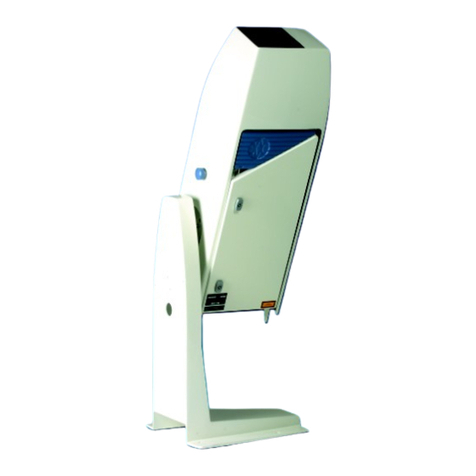

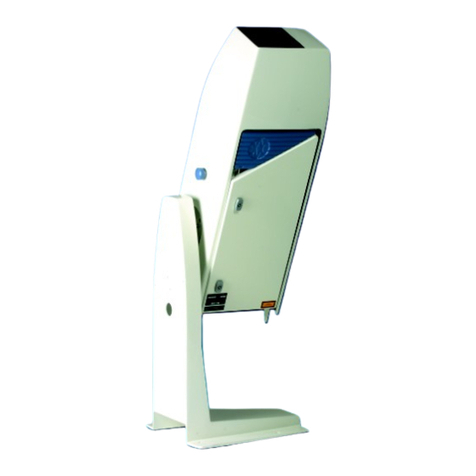

Figure 4. WAA251 assemb y