5

U:\MANUALS\990000\990139

JDS/LRA REV (1) 6-29-2017

North America:

Phone: 800.99VALCO (800.998.2526)

Fax: 419.678.2200

Internaonal:

Phone: (+1) 419.678.8731

Fax: (+1) 419.678.2200

Email: intl.sales@val-co.com

©2016 Valco Companies, Inc.

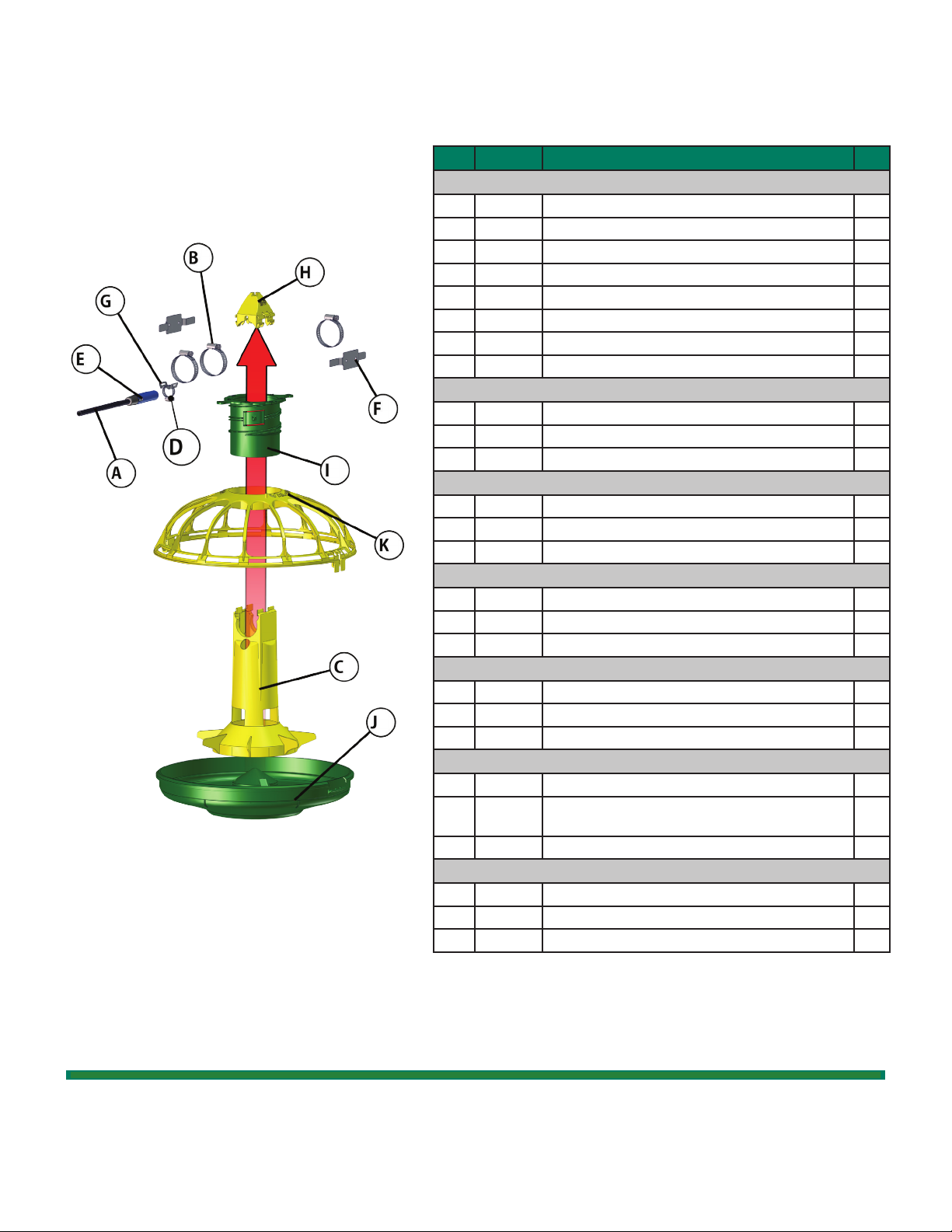

Key Part # Descripon Qty

Interchangeable Parts

A 450965 3/8” CABLE COVER 2

B 451008 1-3/4” SS TUBE CLAMP 3

C 455926 FUZE PROX CONTROL TOWER 1

D455928 7/8” HOSE CLAMP 1

E750437 SENSOR, PROXIMITY, DOL26 1

F820158 FUZE NON-SWING BRACKET 2

G 820177 BRACKET, PROX SENSOR MTG 1

H FE1550 FUZE FEEDER TOWER CAP 1

(parts specic to) 455919

IFE1540 FUZE ADJ COLLAR - STANDARD PAN 1

J FE1610S 14” FUZE SLOTTED STANDARD PAN W/ HINGE & LOCK 1

K FE1620R 14” FUZE PRO GRILL - 14 SPOKE W/ HINGE & LOCK 1

(parts specic to) 455920

IFE1540 FUZE ADJ COLLAR - STANDARD PAN 1

J FE1510S 13” FUZE SLOTTED STANDARD PAN W/ HINGE & LOCK 1

K FE1520R 13” FUZE PRO GRILL - 13 SPOKE W/ HINGE & LOCK 1

(parts specic to) 455921

IFE1540S FUZE ADJ COLLAR - SHALLOW PAN 1

J FE1510LS 13” FUZE SLOTTED SHALLOW PAN W/HINGE & LOCK 1

K FE1520R 13” FUZE PRO GRILL - 13 SPOKE W/ HINGE & LOCK 1

(parts specic to) 455922

IFE1540S FUZE ADJ COLLAR - SHALLOW PAN 1

J FE1610LS 14” FUZE SLOTTED SHALLOW PAN W/ HINGE & LOCK 1

K FE1620R 14” FUZE PRO GRILL - 14 SPOKE W/ HINGE & LOCK 1

(parts specic to) 455923

IFE1540 FUZE ADJ COLLAR - STANDARD PAN 1

J FE1610S 14” FUZE SLOTTED STANDARD PAN W/ HINGE &

LOCK

1

K FE1820R 14” FUZE PRO GRILL - 5 SPOKE W/ HINGE & LOCK 1

(parts specic to) 455924

IFE1540S FUZE ADJ COLLAR - SHALLOW PAN 1

J FE1610LS 14” FUZE SLOTTED SHALLOW PAN W/ HINGE & LOCK 1

K FE1820R 14” FUZE PRO GRILL - 5 SPOKE W/ HINGE & LOCK 1

Standard Pan , Fuze Adj Collar for Standard Pan

and 13 Spoke with Hinge & Lock shown

Control Exploded View and Parts List