Chapter 1. Safety Issue

1-1 Safety Issues to pay attention

1. The basic guidelines for safe operation, the following four conditions must be observed by the operator:

(1) The machine should be operated or maintained by trained technician only.

(2) Read this user manual carefully and understand the contents thoroughly before operation.

(3) For convenience, put this user manual at easy access, near by the machine.

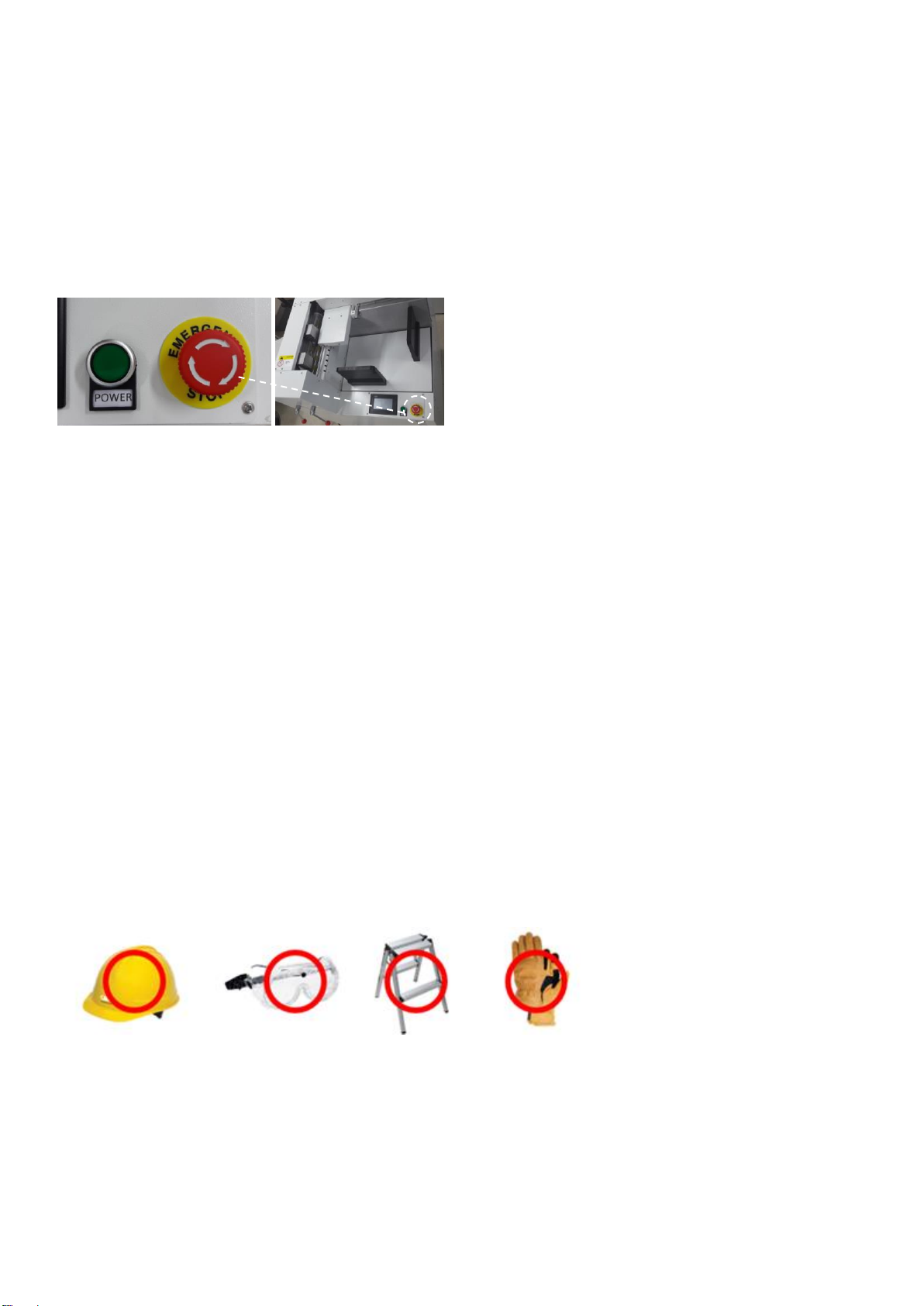

(4) People including operators and maintenance technicians should know the location of emergency stop

button and realize its function and method.

< PICTURE 1-1 >

2. Electric power safety

First of all, make sure all button switches on the machine stand are closed and the ground connection is properly

connected. The power supply used by this unit is 1220V. Circuit breaker needs to be 10A for the main power of this

machine. The Circuit breaker should be in compliance its safety relevant standards.

3. Safety when handling the installation:

To improve the efficiency of the machine, the installation site should be well-ventilated, with good ambient

air quality, and the ambient temperature must not exceed 50 degrees. Avoid rain and direct sunlight.

The following precautions when handling the installation;

(1) Make sure the ground strength is sufficient to support the machine.

(2) Lifting of the machine by lifter should be done by professional operator.

(3) When lifting the machine, nobody is allowed to be under or near the machine.

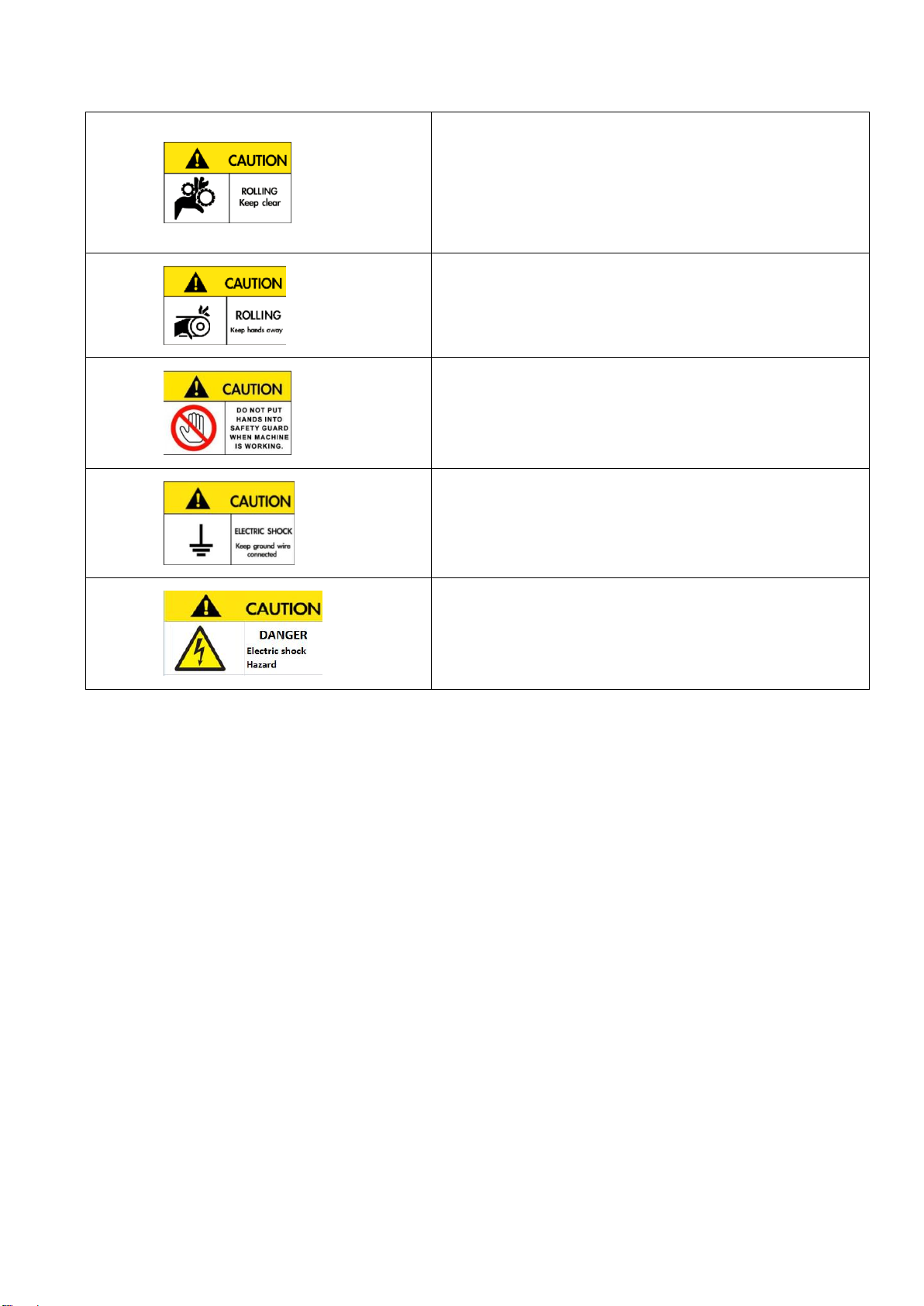

(4) A safety Helmet is required during handling, installation or cleaning.

(5) If it is necessary to reach upper parts on the machine, use a safe and sturdy ladder or platform.

(6) Use a suitable lifting device to lift a heavy object.

(7) Be sure that lifting wire rope is strong enough to handle the weight of the machine or related parts.

(8) Please turn off the power before carrying or installing. If you need to turn on the power, please let other

people know the location of the emergency stop switch in advance.

(9) Wear leather gloves or similar protective equipment when handling, installing or cleaning.

< PICTURE 1-2 >

4. Precautions during operation:

The operator should be familiar with machine’s functions, characteristics and operation methods.

Do not let other untrained people approach to the machine. During running, stretching of hands into the working area

is strongly prohibited. If there is any abnormal situation happening, turn off the power or press emergency stop button

immediately. After that try to find the solutions. Safety precautions during operation are as follows.

(1) Do not remove any safety shields and safety measures.