3

To the reader

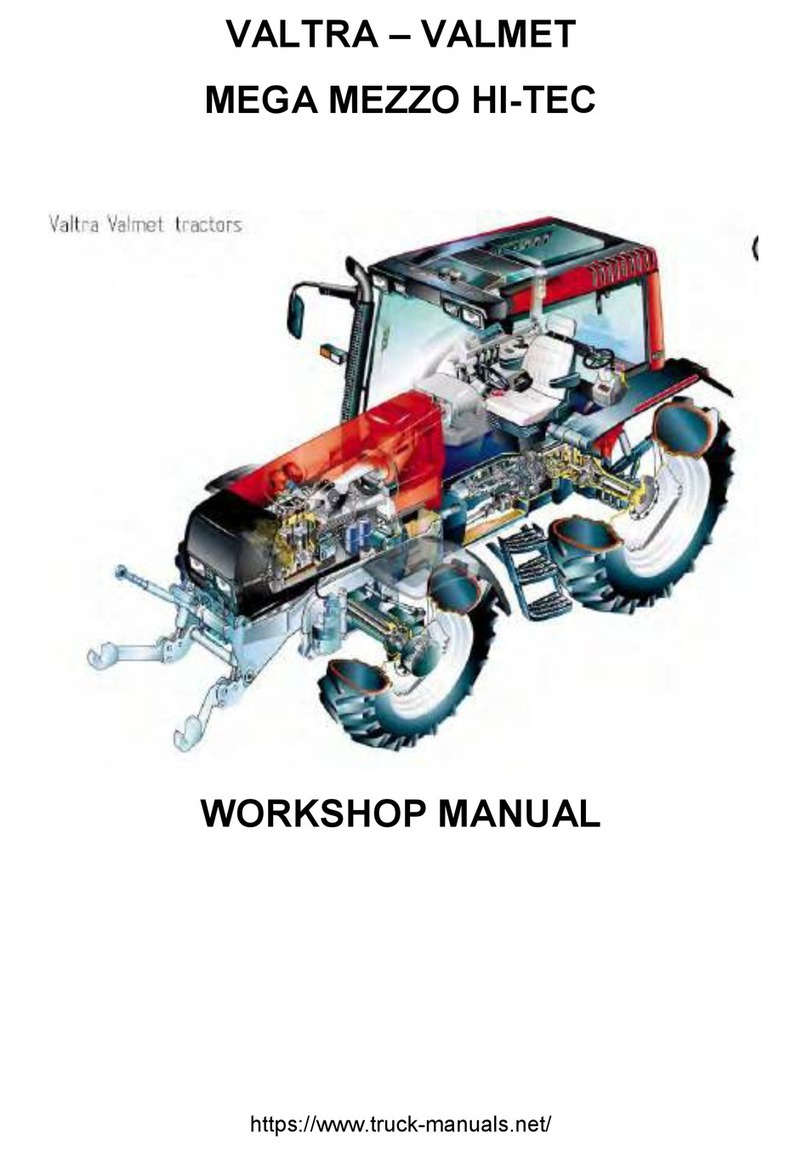

The Service Manual for the ValtraValmet tractors is intended to be a practical reference source to be

used in workshop. The repair instructions in the manual are based on methods which have been

worked out in practice during normal workshop conditions and which are based on the use of special

tools from the manufacturer when stated in the instructions. The manual also contains descriptions of

the design and function of the components.

Detailed maintenance instructions can be found in Operator's Manual.

The Service Manual will be continually updated with new revised pages which should be inserted in the

manual. lterations and additions will first appear as service bulletins.

Only genuine Valmet spare parts should be used to ensure the best possible function of the machine.

Certain operations should be carried out with the aid of special tools designed by Valmet.

Valmet Tractors Inc.

Tractor Service

IM ORTANT!

ValtraValmet 95, 105 and 115 tractors are based on ValtraValmet agricultural tractors as follows:

- 95 is based on 6400DW tractor

- 105 is based on 6600 tractor

- 115 is based on 6800 tractor

ValtraValmet X100, 110H and X120 tractors are based on ValtraValmet agricultural tractors as follows:

- X100 is based on 6550Hi tractor

- X110 is based on 6650Hi tractor

- X120 is based on 6850Hi tractor

95- X120 tractors have frame steering (in 95-X120 tractors there is a new middle frame in place of the

fuel tank which is fitted on the corresponding agricultural tractors) and 95-X120 can have special auxĆ

iliary hydraulics (e.g. special, fixed front loader and its control), which are not fitted on correcponding

agricultural tractors. However, other vehicle components are the same as in corresponding agricultural

tractors.

Find manuals at https://best-manuals.com