User manual

greenpin.com

safer

working

improved

efficiency

As strong as steel, a

fraction of the weight

Green Pin Tycan®Lifting Chain

Green Pin Tycan

®

has been created from the world’s strongest

man-made fibre, Dyneema

®

, and is a link chain that has all the

performance and flexibility of steel chain but is a fraction of the

weight. It is very safe to use, non-corrosive and waterproof. In

fact, it even floats! The soft touch and light weight makes Green

Pin Tycan

®

easy to use, allows quicker application and greatly

reduces the potential of damage to cargo, a critical factor when

handling objects with sensitive surfaces. By using Green Pin

Tycan

®

companies achieve greater efficiency and a safer working

environment for their staff.

Quality assurance

• Every chain length is proof load tested to 2 times Working Load Limit

(WLL).

• Visual inspection is carried out on each chain link to detect

possible defects.

• A 5-link sample of every 1000 meters (0.62 miles) produced is

tested to destruction to confirm MBL.

• Green Pin Tycan

®

has a DNV GL Type Approval.

• Declaration of conformity to the Machinery Directive 2006/42/

EC with relevant CE marking.

Where and how can Green Pin Tycan

®

Lifting Chain be used

• Green Pin Tycan

®

Lifting Chain is a general purpose lifting chain

that can be used within the limits as set forth in this user manual.

• Green Pin Tycan

®

Lifting Chain can be used in min/max

environmental temperatures, but should not be exposed to

temperatures above +70°C (158°F).

• Green Pin Tycan

®

Lifting Chain is able to lift loads safely only up

to the designated WLL, but never exceeded.

• Green Pin Tycan

®

Lifting Chain is able to lift loads safely only

when the relevant load reduction factor is taken into account.

Do not exceed the WLL.

• Green Pin Tycan

®

Lifting Chain can be used on land, at sea and

in a subsea environment.

• Green Pin Tycan

®

Lifting Chain should be used under static or

near-static conditions.

Verification before first use

Before first use of Green Pin Tycan

®

Lifting Chain it should be

ensured ‘that’:

• Green Pin Tycan

®

Lifting Chain meets the exact requirements

specified in the order.

• The valid manufacturer certificate and CE declaration are available

for examination and/or verification.

• Ensure that manufacturer’s label(s) are present and legible and that

the label(s) contain the same information as the manufacturer’s

certification.

• The users of the sling have received appropriate instruction and

training.

Verification before each use

• Check Green Pin Tycan

®

Lifting Chain for any damage, defects

or missing ID tags prior to each use. Never use damaged

Green Pin Tycan

®

Lifting Chain.

• Connect Green Pin Tycan

®

Lifting Chain to recommended

components as mentioned further in this manual or to certified

components with a maximum surface roughness of 5 microns

and adhering to below values:

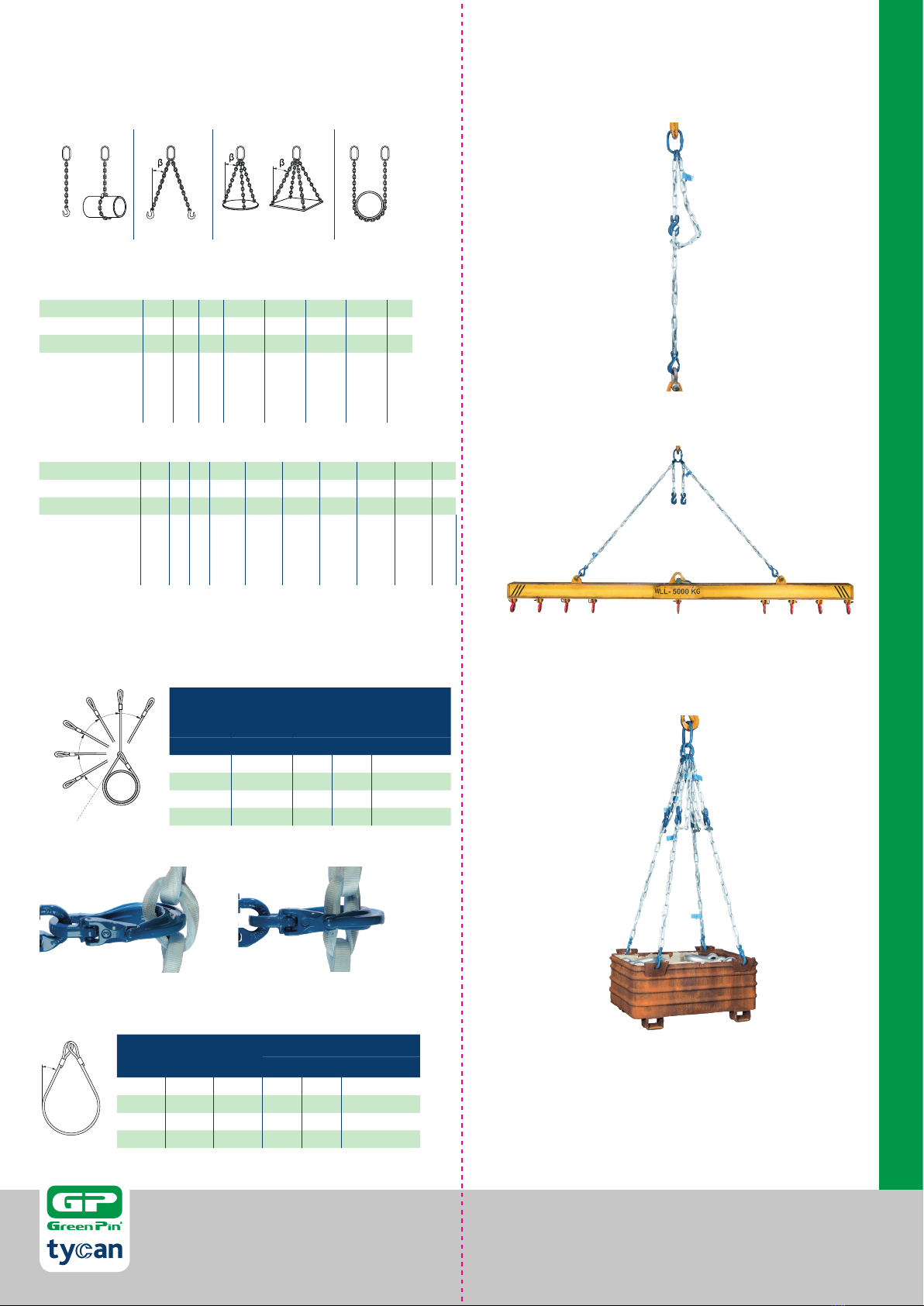

link

size

working

load limit

width

link

thickness

link

length

inside

links

per mtr

elongation

at MBL

weight

per mtr layers

mm t

a

mm

b

mm

c

mm %kg

11x15 2.6 15 11 100 10 5 0.32 6

11x20 4 20 11 100 10 5 0.47 6

15x25 5 25 15 100 10 5 0.58 8

13x30 6.8 30 13 125 8 5 0.75 7

Material: Made with 100% Dyneema

®

; layers of

webbing in a Mobius twist with stitching

on each side

Safety Factor: MBL equals 4 x WLL

Temperature Range: -40°C

(-40°F)

up to +70°C

(158°F)

Certification:

MTC

b

DNV GL TA CEDNV GL TQ

FCHLIFT

link

size

working

load limit

width

link

thickness

link

length

inside

links

per mtr

elongation

at MBL

weight

per mtr layers

inch tinch inch inch %lbs

7/16 x19/32 2.6 19/32

7/16 4 10 5 0.70 6

7/16 x25/32 425/32

7/16 4 10 5 1.04 6

19/32x1 5 1 19/32 4 10 5 1.28 8

1/2x1 3/16 6.8 1 3/16

1/24 23/32 8 5 1.65 7

link

size

lifting

capacity

minimum

pin diameter

minimum

clevis width

maximum

clevis width

mm tmm mm mm

11x15 2.6 13 15.5 18

11x20 4 16 20.5 24

15x25 5 16 26 31

13x30 6.8 20 31 37