Operating Instructions

Van Walt Ltd | Prestwick Lane | Grayswood | Haslemere | Surrey | GU27 2DU | Tel. 01428 661 660 | Fax. 01428 656 808 | www.vanwalt.com

Rain Gauge

3

VAN WALT

Monitoring your needs

1.2 General

The e+ RAIN sensor is an intelligent sensor that consists of a specic sensor section as well as a so-

called datalogger that houses the micro-electronics. The datalogger has an internal memory for

storing the measurements but also provides the means for reading the digital data. To make this

1.4 Measuring section

The rain gauge is part of the e+ RAIN sensor and is manufactured from UV-proof

synthetic material. It furthermore has an aerodynamic design which ensures

that measurements suffer as little as possible interference from the wind. The

system operates on the so-called ‘tipping bucket’ method, in which rain is

captured via a funnel and poured into a basin that is xed on a hinge. A pre-

determined amount of rain results in the bucket tipping and emptying itself. Brief

contact results with a switch. In this way the amount of rain equals the number of

switch contacts during a specic time unit. The rain gauge is tted with a 5-pole

connector for connection with the datalogger.

The raingauges tipping bucket mechanism is immobilised before shipping to prevent damage

in transit. To release the mechanism, remove the funnel from its base by unscrewing the three

thumbscrews. Remove the piece of foam from under the bucket mechanism. This foam may be

saved and used whenever the raingauge is moved

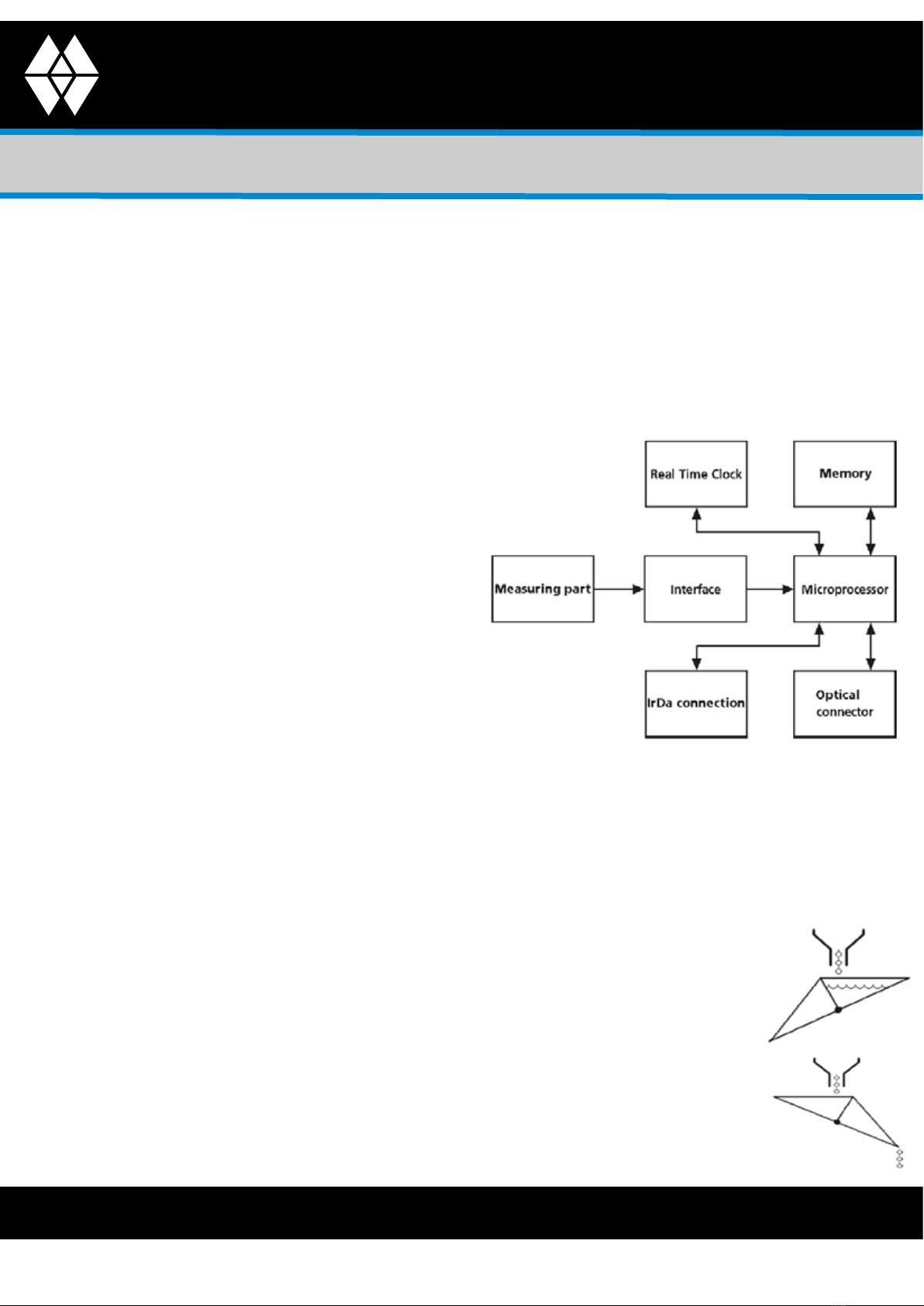

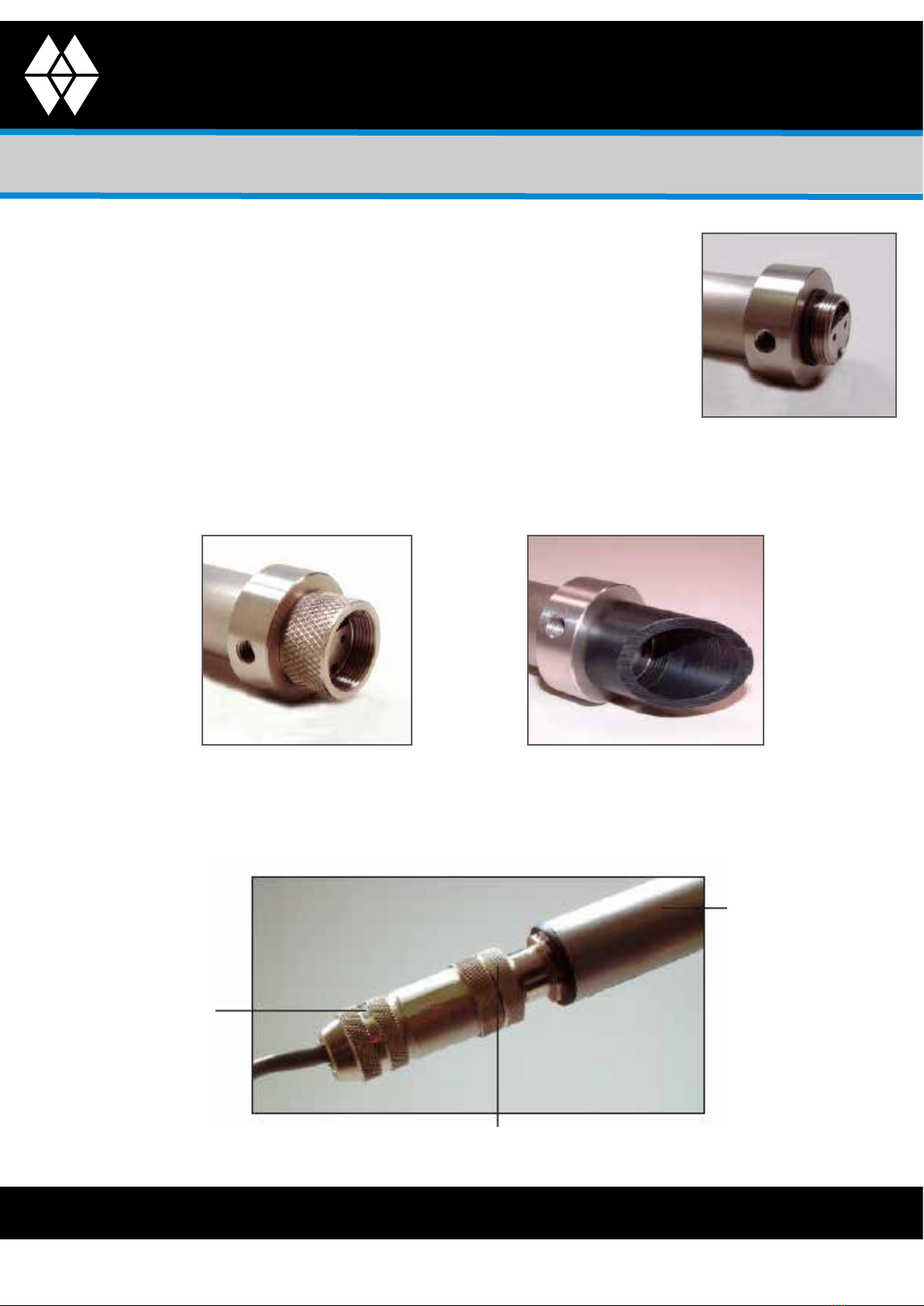

1.3 Datalogger

The datalogger is designed around a

microprocessor that performs the role of saving

periodical measurements in the memory and

enables a connected device to read the stored data. The signal

that the sensor part delivers to the interface is converted into data

that can be processed by the microprocessor. The microprocessor

records the data in the memory with a sample speed, based on the

internal Real Time Clock (RTC). It is possible by means of available communication channels,

namely the optical connector and the IrDa link, for a device that has been connected to

communicate with the microprocessor and read the data stored in the memory or adjust

settings such as the sample speed, for instance. The datalogger of the e+ sensor has 2 measuring

channels and the memory range is divided proportionally over the available channels. The

memory has the capacity to store 30.000 measurements per channel.

possible the datalogger has an optical connector for a

communication cable or a readout unit or an IrDa interface for

communication by means of an IrDa readout unit. This offers the

advantage of intercompatibility, reliable transfer of data and

the possibility of stand-alone use.