S/N CB50600021 – UP (Weld-deck) i

Table of Contents

FOREWORD....................................................................................................................................................................1

LITERATURE INFORMATION ............................................................................................................................................. 1

MACHINE DESCRIPTION................................................................................................................................................... 1

SAFETY........................................................................................................................................................................... 1

OPERATION..................................................................................................................................................................... 1

MAINTENANCE................................................................................................................................................................ 2

MAINTENANCE INTERVALS.............................................................................................................................................. 2

CALIFORNIA PROPOSITION 65.......................................................................................................................................... 2

CERTIFIED ENGINE MAINTENANCE .................................................................................................................................. 2

SAFETY SECTION.........................................................................................................................................................2

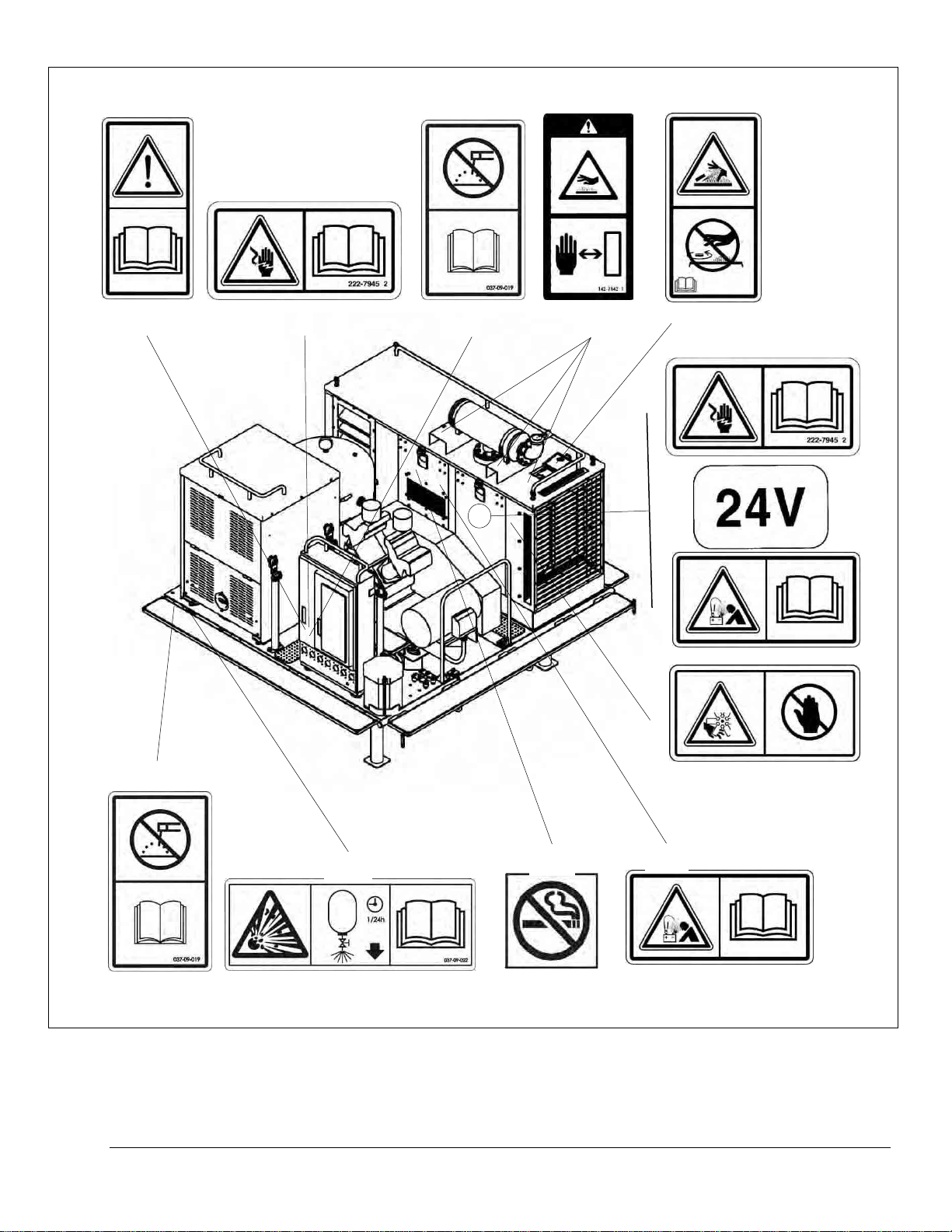

SAFETY SIGNS AND LABELS............................................................................................................................................. 2

Do Not Operate (1)..................................................................................................................................................... 6

Electrical Shock (2) .................................................................................................................................................... 6

Do Not Weld on the Machine (3)................................................................................................................................. 8

Hot Surface (4)........................................................................................................................................................... 9

Hot Fluid Under Pressure (5) ................................................................................................................................... 10

Electrical Shock (6) .................................................................................................................................................. 11

24 Volt DC system (7)............................................................................................................................................... 12

Drain Air Receiver Daily (11)................................................................................................................................... 16

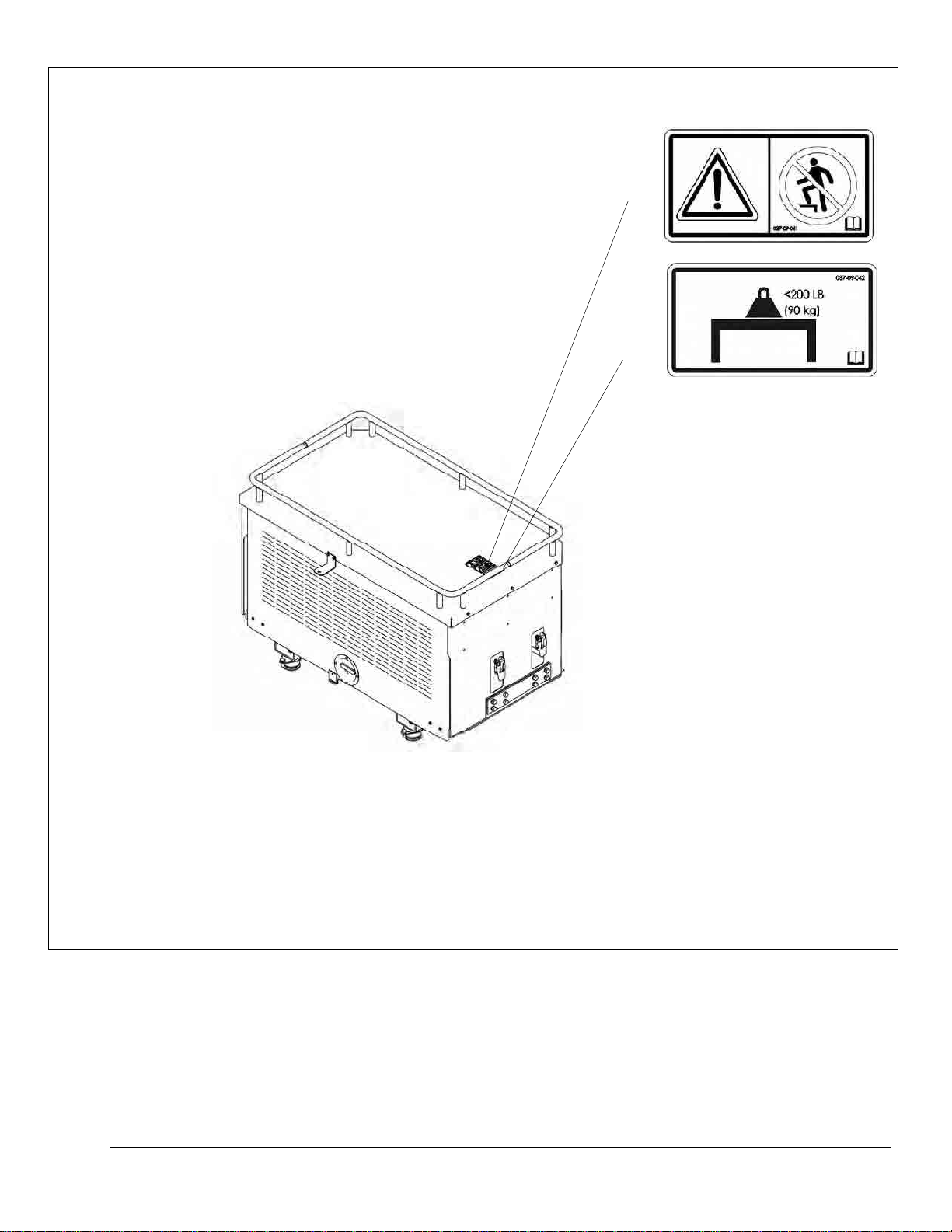

Do Not Step (12)....................................................................................................................................................... 17

Maximum surface load capacity (13)......................................................................................................................... 18

ETHYL ETHER CYLINDER...................................................................................................................................... 19

Batteries................................................................................................................................................................... 20

GENERAL HAZARD INFORMATION.................................................................................................................................. 21

PRESSURE AIR AND WATER............................................................................................................................................ 22

TRAPPED PRESSURE ...................................................................................................................................................... 22

FLUID PENETRATION ..................................................................................................................................................... 22

CONTAINING FLUID SPILLAGE ....................................................................................................................................... 22

INHALATION ................................................................................................................................................................. 23

Exhaust..................................................................................................................................................................... 23

Asbestos Information ................................................................................................................................................ 23

DISPOSE OF WASTE PROPERLY ...................................................................................................................................... 23

CRUSHING PREVENTION AND CUTTING PREVENTION ...................................................................................................... 23

BURN PREVENTION........................................................................................................................................................ 24

Coolant..................................................................................................................................................................... 24

Oils .......................................................................................................................................................................... 24

Batteries................................................................................................................................................................... 24

FIRE PREVENTION AND EXPLOSION PREVENTION............................................................................................................ 24

General.................................................................................................................................................................... 24

Battery and Battery Cables ....................................................................................................................................... 26

Wiring...................................................................................................................................................................... 27

Lines, Tubes and Hoses............................................................................................................................................. 27

Ether........................................................................................................................................................................ 28

Fire Extinguisher...................................................................................................................................................... 28

Fire Safety................................................................................................................................................................ 28

Fire Extinguisher Location ....................................................................................................................................... 29

ELECTRICAL CABLES AND WIRE-HARNESSES................................................................................................................... 29

ELECTRICAL STORM INJURY PREVENTION...................................................................................................................... 29

BEFORE STARTING GENSET-ENGINE .............................................................................................................................. 29

GENSET-ENGINE STARTING........................................................................................................................................... 29

BEFORE OPERATING EQUIPMENT ................................................................................................................................... 30

VISIBILITY INFORMATION.............................................................................................................................................. 30

OPERATION................................................................................................................................................................. 30

MACHINE OPERATING TEMPERATURE RANGE ................................................................................................................ 30

MACHINE OPERATION ................................................................................................................................................... 30

MACHINE PARKING ....................................................................................................................................................... 31

GENSET ENGINE STOPPING ............................................................................................................................................ 31