7

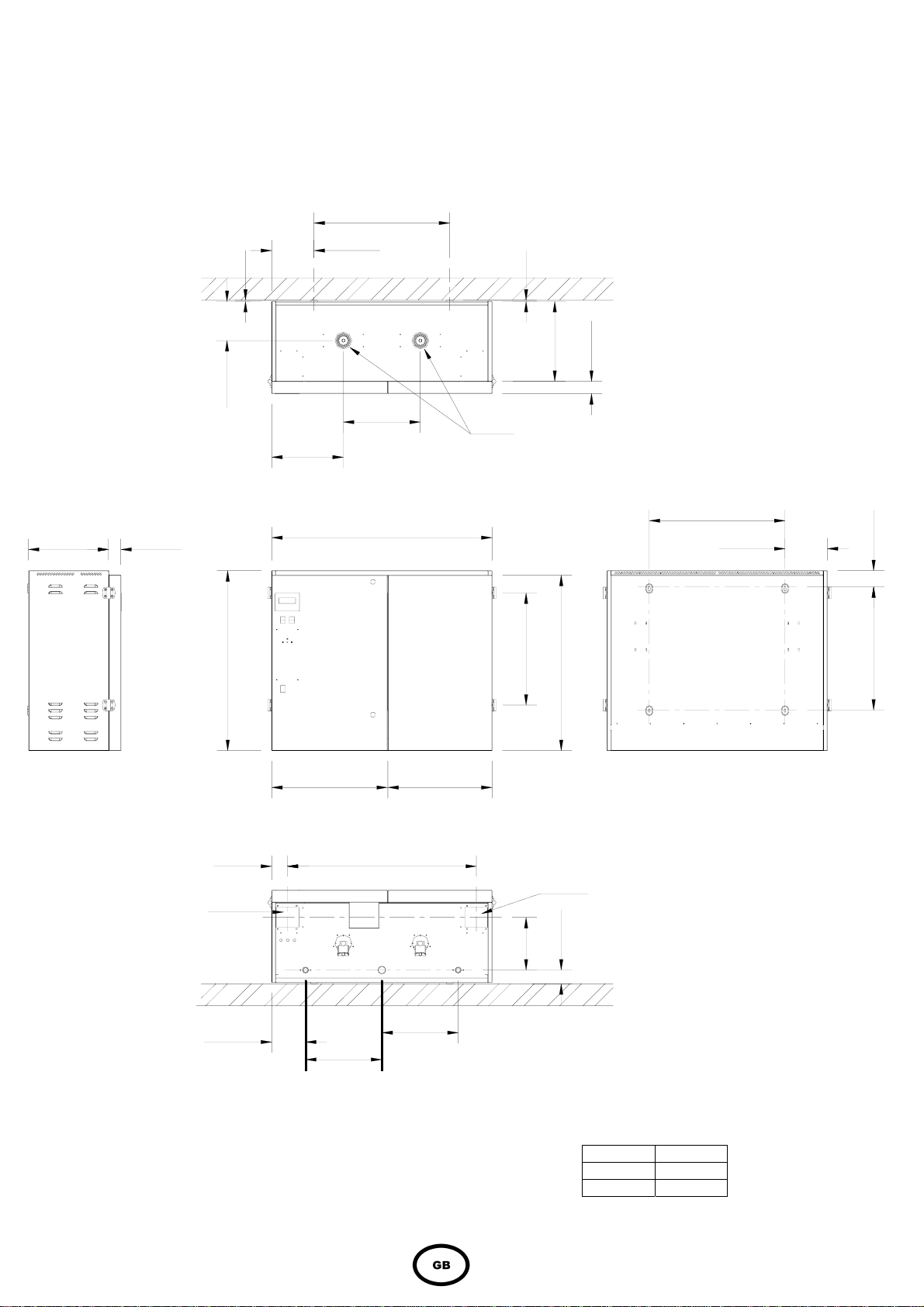

1.1.2 LR weights

The unit dry weight is the delivered unit with no

water in unit, the wet weight is the operational

weight when the unit is running . The RDU weight

must be added to the unit weight if fitted on top of

the Resistive unit.

Resistive model Dry Kg Wet Kg RDU Kg

LR5 and LR5P 34 48 6

LR10 and LR10P 35.5 49.5 10

LR20 and LR20P 39 65.5 12

LR30 and LR30P 40 66.5 14

LR40 and LR40P 72.5 125.5 NA

LR50 and LR50P 73.5 126,5 NA

LR60 and LR60P 74.5 127.5 NA

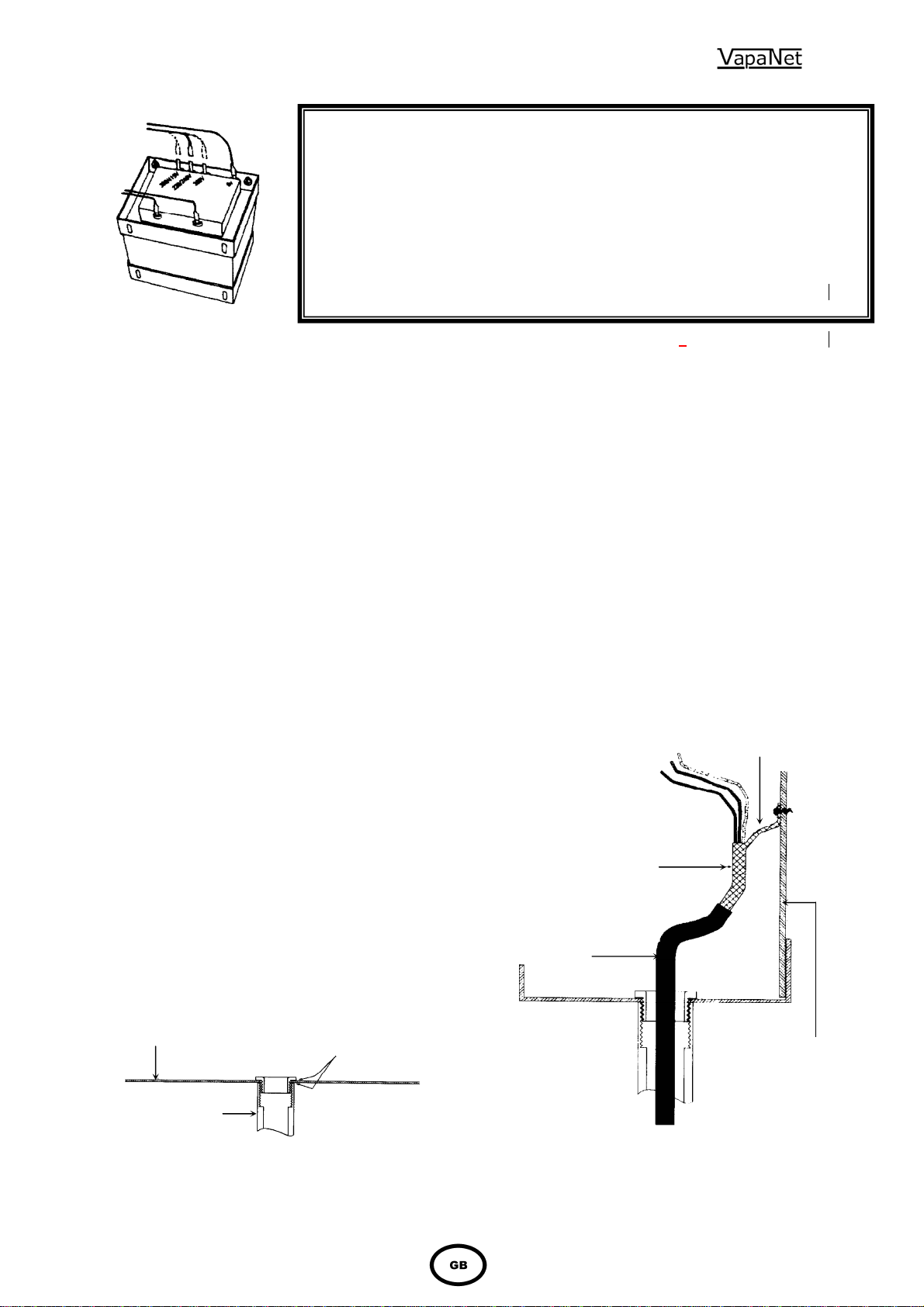

1.2 Positioning the steam pipes

1.2.1 General

Steam pipes should be positioned as shown below,

allowing a minimum rate of fall back to the unit of

12% to allow the free flow of condensate back to the

unit. If the above fall is not possible, then

condensate separators must be fitted as shown in

figure 1.

The position of the steam pipe or multipipe in a air-

conditioning system relative to other items such as

bends, filters, heat exchangers, etc., is critical. The

steam pipe must not be located closer to such item,

than the entrainment distance, and must be decided

by the design engineer responsible for the project.

Do's

Do obtain project engineer's instruction/drawing for

chosen location of pipe

Do obtain project engineer's instruction/drawing for

pipe position relative to the top & bottom of the

duct (or sides if airflow is vertical.

Do check if alternative slope of Ø35mm pipe has

been specified requiring rotation of pipe in its

socket before installation.

Do use bracket/lug on the end of Ø54mm pipes for

extra support.

1.2.2 Steam Hose Connection

Do's

Do use Vapac steam hose or well insulated copper

pipe.

Do keep steam hose as short as possible (under 2m

for max efficiency).

Do arrange to have a vertical rise immediately over

the unit of 300mm.

Do use the full height available between the unit and

steam pipe to provide maximum slope (min 12-

20% for condensate to drain back to the steam

cylinder (or down to a condensate separator).

Always provide a continuous slope.

Do provide adequate support to prevent sagging

a) fit pipe clips every 30-50cm

or b) support straight lengths on cable trays or

in heat resistant plastic pipe.

Do ensure radius hose bends are fully supported to

prevent kinks developing when in service.

Do add extra insulation to steam hose for longer

runs (2m-5m) and in cold ambient conditions to

avoid excess condensate and reduction in

delivered output.

Don'ts

Don't allow steam hose to develop kinks or sags.

Don't include horizontal runs or 90oelbows in the

steam line.

Steam Distribution Pipe requirement

Resistance Heater

Unit Model LR05

LR10

LR05P

LR10P

LR20

LR30

LR20P

LR30P

LR40

LR50

LR60

LR40P

LR50P

LR60P

35mm

Pipe No.

54mm ∅. Pipe No. 1

- -

1 -

2

* Duct Pressure Pa. +2000

-600 +2000

-600

* For systems with a duct pressure over +1000 Pa. It may

be necessary to fit a suitably sized trap in the water feed

line between the Vapac tundish and the feed drain

manifold to ensure water can enter the cylinder when it is

empty.

35mm

Pipe Selection 54mm ∅Pipe Selection

Duct width

B mm In-duct Length

L mm Duct width

B mm In-duct Length

L mm

320-470

470-620

620-770

770-920

920-1070

1070-1200

300

450

600

750

900

1050

700-950

950-1450

1450+

(Kg)

650 (1.8)

900 (2.2)

1400 (3.2)

For guidance on positioning of steam pipes see

Appendix 1.

For guidance on use of Multipipes see Appendix

2.

R min for 35

Pipe = 250mm

R min for 54 ∅Pipe = 500mm

Flexible Steam

Pipe.

No Sags!

Distance to first

bend.

VAPAC

HUMIDIFIER

Flexible Steam

Pipe.

Flexible pipe coupling to

connect Steam pipe to Duct

pipe coupling length to allow

for line movement and

expansion. Coupling clamp

with Hose clips each end.

35 or 54 mm

copper or

stainless steel

steam pipe with

Insulation.

Fig 6