TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING :

:

:

:

Note:

Note:

Note:

Note: The

The

The

The foot

foot

foot

foot pedal

pedal

pedal

pedal switch

switch

switch

switch should

should

should

should be

be

be

be set

set

set

set to

to

to

to OFF

OFF

OFF

OFF at

at

at

at all

all

all

all times

times

times

times

unless

unless

unless

unless using

using

using

using a

a

a

a foot

foot

foot

foot pedal.

pedal.

pedal.

pedal. The

The

The

The foot

foot

foot

foot pedal

pedal

pedal

pedal switch

switch

switch

switch is

is

is

is located

located

located

located on

on

on

on

the

the

the

the front

front

front

front of

of

of

of the

the

the

the machine,

machine,

machine,

machine, it

it

it

it is

is

is

is a

a

a

a black

black

black

black switch

switch

switch

switch with

with

with

with a

a

a

a triangle

triangle

triangle

triangle

logo

logo

logo

logo next

next

next

next to

to

to

to it.

it.

it.

it.

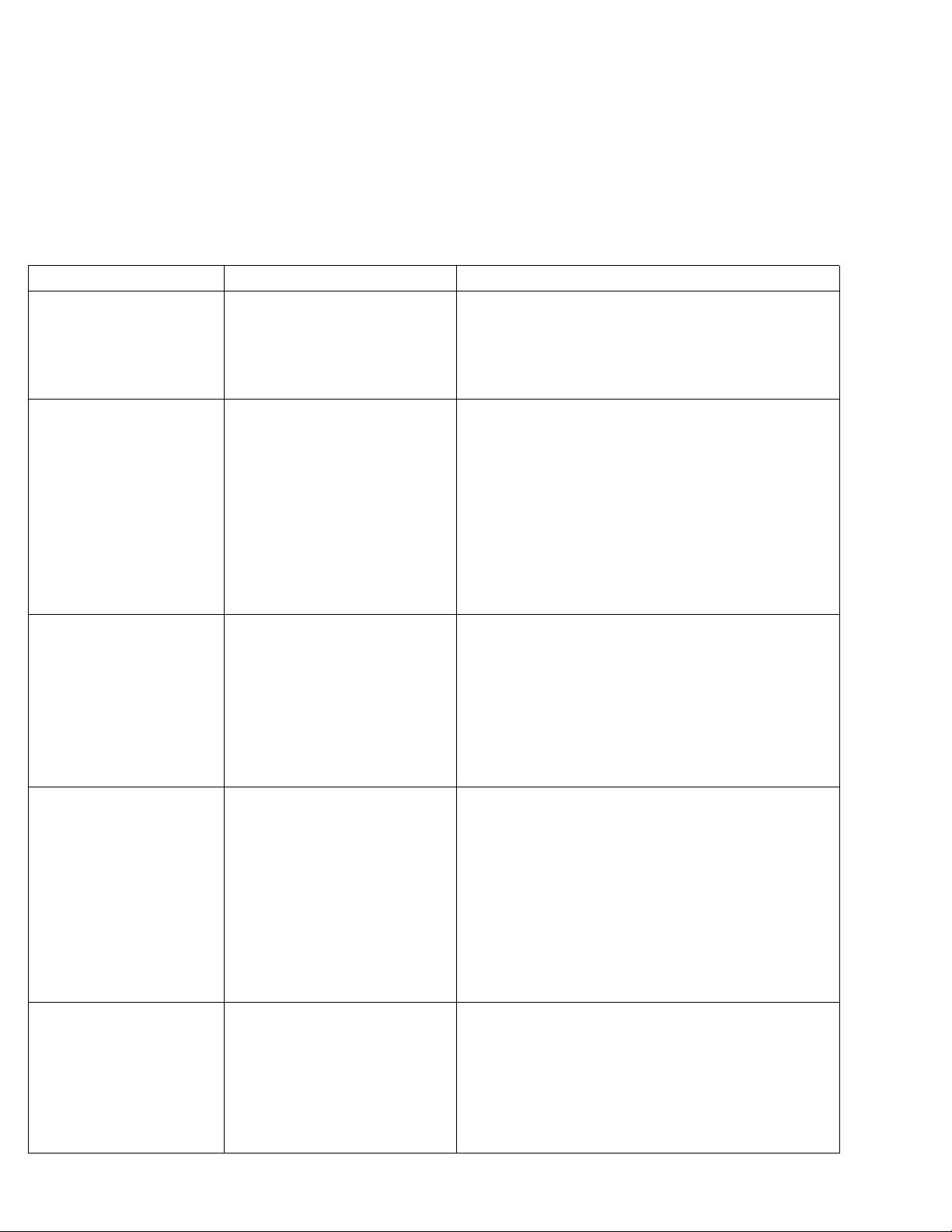

Problem

Problem

Problem

Problem Cause

Cause

Cause

Cause Solution

Solution

Solution

Solution

Torch d oesn ’ t turn on Power switch is fff

Problem with air supply

Ground clamp not attached

Turn power switch ON

Check air supply

Properly attach ground clamp

Sparks Shooting

Upward

Plasma torch not piercing

material

Torch is too far from

material

Improper grounding of

material

Speed

Increase the current.

Decrease the distance between the torch and

cutting stock

Properly attach the ground clamp or move

ground clamp closer to work

Slow down and reduce cutting speed

Dross build up Material/tool is too hot

Current is too high

Cutting speed is too slow

Worn out torch parts

Allow time for material/tool to cool down

Reduce current

Increase cutting speed

Turn machine off. Inspect and replace

consumables as necessary.

Arc stops during cut Cutting speed is too slow

Torch is too far from

material

Worn out torch parts

Improper grounding of

materia l

Increase cutting speed

Decrease the distance between the torch and the

stock

Turn machine off. Inspect and replace

consumables as necessary.

Properly attach the ground clamp or move

ground clamp closer to work

L ow penetration Cutting speed is too fast

Torch is tilted too far

Metal too thick

Reduce cutting speed

Adjust torch position

More than one pass may be needed

Input current of machine may be insufficient