3

4

2

1

MALE RIB

SEALANT

FEMALE RIB

SEALANT

FEMALE RIB

MALE RIB

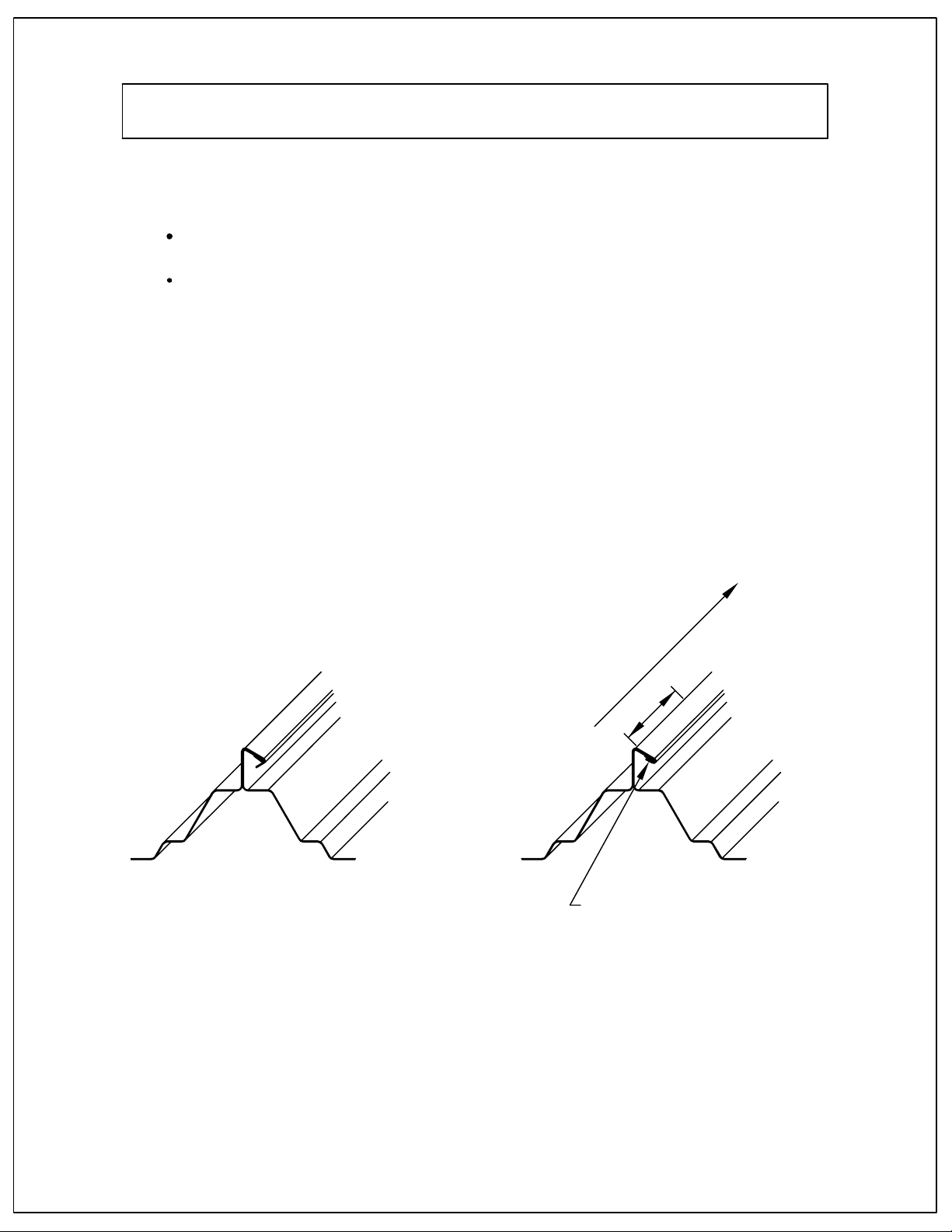

FIG. 1

CORRECT

FIG. 1 INCORRECT

FIG. 2

Model No. VP-900

6

4. PREPARATION FOR SEAMING

A. Check Seamer Tool

1. Check seamer tool for Grease.

When in use, tool should be

lubricated every day. If seamer tool

is in sustained, continuous use,

grease every four (4) hours. Only

one (1) shot of grease required at

each point shown (1, 2 & 3).

2. Lubricate tool at grease fittings,

using only "Lithium Grease". See

figure 1 for grease fittings locations.

3. Clean forming rolls with WD-40 to

remove dirt, excessive grease and

sealant build-up on rolls.

Clean Mastic from rollers daily.

4. Check tool for loose parts, screws,

wheels, forming rolls, and electrical

connections. Repair & replace

as required.

5. Lubricate drive chain, which is

enclosed under rear chain cover.

Loosen and remove one (1) set

screw from cover. Apply one (1) shot

of grease to each drive sprocket as

required after 8 hour use

(see figure 4 above).

B. Panel

1. Panels should be wiped down at the areas where tape

mastic or tube sealant is to be applied.

2. BEFORE SEAMING, IT IS IMPORTANT TO WIPE THE

SEAM CLEAN WITH SOAPY CLOTH IMMEDIATELY

BEFORE SEAMING THE PANEL. THIS STEP WILL

DRAMATICALLY REDUCE THE CHANCE OF MARRING

THE SEAMS AT THE CLIP LOCATIONS.

3. Check seams to ensure they are engaged prior to

seaming. See Figure 1 - Correct and Figure 2 -

Incorrect below