F-700

4

Contents

1 Basic information ............................................................................................................... 5

2 Foreword ............................................................................................................................ 6

2.1 Basic warnings ........................................................................................................... 6

3 O eration safety ................................................................................................................. 7

3.1 Safety regulations....................................................................................................... 7

3.2 Declared noise and vibration values........................................................................... 8

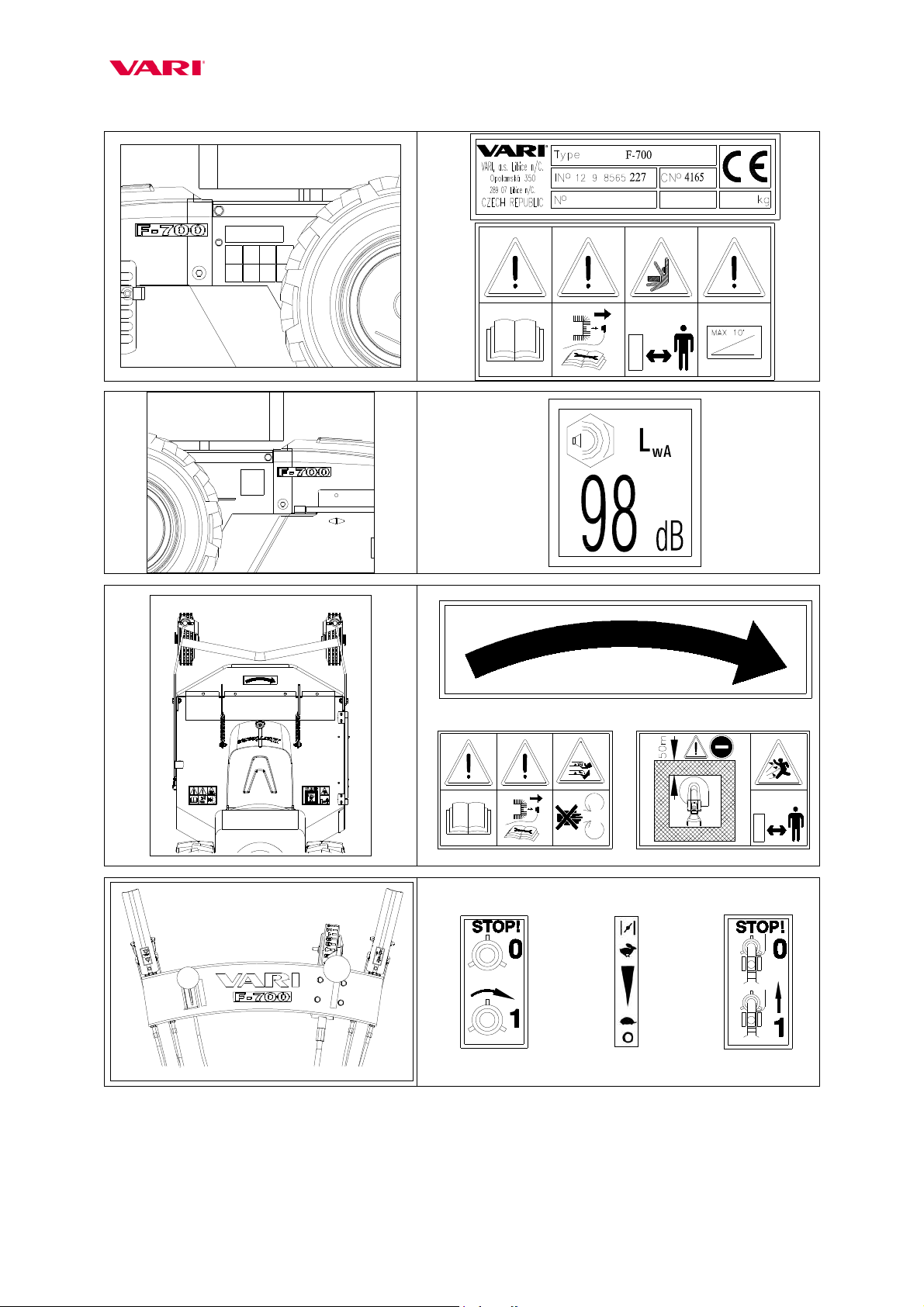

3.3 Safety ictogra hs...................................................................................................... 8

4 Use, technical s ecifications and technical descri tion of the machine .......................... 10

4.1 Machine use.............................................................................................................. 10

4.2 O tional attachments................................................................................................ 10

4.3 Technical s ecifications ........................................................................................... 10

5 Instructions for use........................................................................................................... 11

5.1 Machine assembly.................................................................................................... 11

5.2 Adjustment of handlebars......................................................................................... 13

5.3 Putting into o eration............................................................................................... 14

5.4 Starting the cutting blade.......................................................................................... 14

5.5 Machine travel forward and back............................................................................. 15

5.6 Machine sto ............................................................................................................ 16

5.6.1 Sto ing on the lain........................................................................................ 16

5.6.2 Sto ing on the slo e ....................................................................................... 16

5.7 Working with the machine ....................................................................................... 16

5.7.1 Adjustment of cutting height............................................................................ 17

5.7.2 Travel s eed choice.......................................................................................... 17

5.7.3 The way of stand cutting .................................................................................. 18

5.7.4 Problems at cutting........................................................................................... 18

5.7.5 Cutting on slo es.............................................................................................. 19

5.7.6 Machine trans ort with engine switched off.................................................... 19

5.7.7 Cutting of high grass stands ............................................................................. 20

6 Maintenance, care and storage ......................................................................................... 20

6.1 Machine lubrication.................................................................................................. 20

6.1.1 Gear oil change and re lenishment .................................................................. 20

6.1.2 Engine oil re lacement..................................................................................... 20

6.2 Tightening of bolted connections............................................................................. 21

6.3 Working blade re lacement and shar ening ............................................................ 21

6.4 Re lacement of V-belts and adjustment of tension ulleys ..................................... 22

6.4.1 Re lacement of V-belts.................................................................................... 22

6.4.2 Adjustment of tension ulleys.......................................................................... 23

6.5 Setting u ulley wires, blade brake ........................................................................ 24

6.6 Adjustment of the automatic brake .......................................................................... 25

6.7 The table of service o erations................................................................................. 26

6.8 Diagnostics of driving roblems .............................................................................. 26

6.9 Washing and cleaning of the machine...................................................................... 26

6.10 Machine storage ....................................................................................................... 27

6.11 Dis osal of ackaging and machine after the end of service life............................. 27

7 Instructions for ordering s are arts................................................................................. 27

8 Contact to manufacturer................................................................................................... 28

9 The list of arts................................................................................................................. 28

10 Letter of Guarantee....................................................................................................... 43