The Instruction Manual and Safety Instructions must be read and understood by anyone

operating the Vastex Conveyor Drying System.

The operator should read and understand the instruction manual before operating this equipment.

Store instruction manual and safety instructions near equipment for easy access to operators.

VASTEX Conveyor Drying System is intended for the curing of non-flammable inks on screen printed

materials. Do not use for any other purpose unless authorized by Vastex International, Inc. Use of this

equipment for any other purpose can be dangerous and may cause damage to this equipment, voiding

the warranty.

It is recommended that the area around this equipment be designated as a work area and only author-

ized employees be allowed in the area.

Children and pets must be kept clear of the work area.

Do not place any objects on top of the drying chamber. Surfaces are hot!

Never leave equipment unattended.

Do not operate conveyor or dryer with any cover or guard removed.

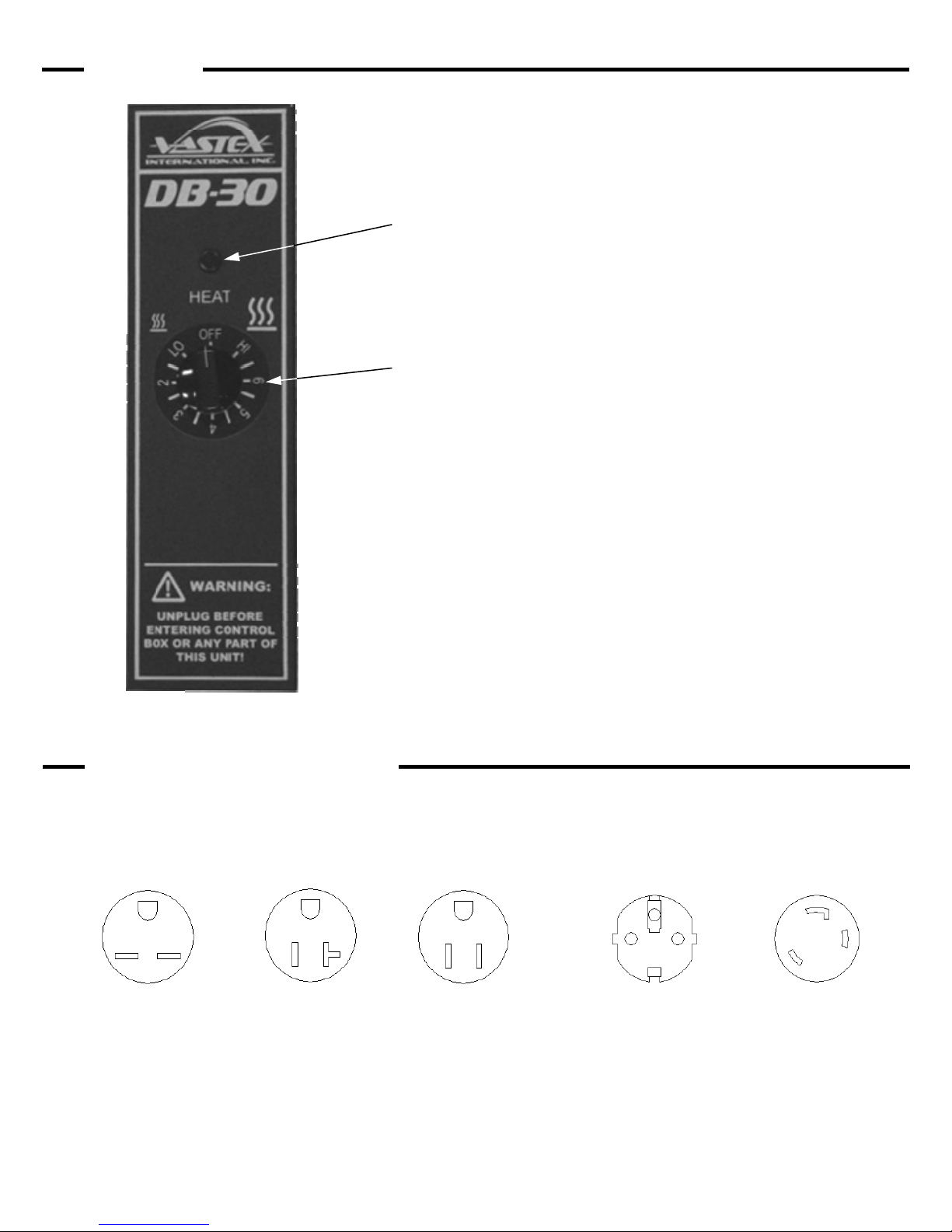

Operator must be familiar with controls of the dryer and conveyor.

Never put excessive load on the conveyor belt.

Before starting production, the operator must check that all covers and guards are in place, no material

has been left on the conveyor, and the work area is clear of obstructions.

Switch on and verify conveyor belt is moving before turning on the heat.

Allow dryer to cool to 300°F (149°C) before switching off conveyor.

Always turn off power at the main disconnect at the end of production.

In case an abnormal symptom occurs, for example excessive vibration, noise, and strong smell or

smoke development, turn off the VASTEX Conveyor Drying System and contact a qualified technician.

Immediately turn off the VASTEX Conveyor Drying System if products become jammed in the drying

chamber or conveyor belt.

Do not remove any cover or guard until power at the main disconnect is switched off and locked out.

No unauthorized persons are to be allowed inside the control boxes.

Turn off and lock out power at the main disconnect before any cleaning or maintenance.

Only qualified technicians should be allowed to make repairs on the VASTEX Conveyor Drying System.

Noise and vibration: This equipment does not produce noise in excess of 70 dB(A) at workstations.

Stability during use, transportation, assembly, dismantling when out of service, testing, and fore-

seeable breakdowns: This equipment is designed and expected to be stable during all foreseeable con-

ditions, so long as the procedures and instructions given in this manual are followed. When dryers are as-

sembled onto legs, it is recommended that two or more people stand the unit upright after bolting legs on.

Safe handling, transport, and storage: Before storing the unit, follow the shutdown procedure on P. 8 to

allow the heater assembly to cool properly. No special handling considerations are necessary, except to

be aware of the weight of the equipment and take standard precautions for moving such weights:

DB-30:

Main Unit: 265 lbs (120.2 kg)

Optional Legs: 30 lbs (13.6 kg)

Optional locking casters are available for all DB-series dryers equipped with legs. When equipment is

to be moved frequently, it is recommended that these be installed.

Introduction

Congratulations, you have chosen a VASTEX conveyor curing system. VASTEX has been designing and

building dryers since 1960 and has the knowledge and expertise to supply a quality dryer and help you keep it running

for years to come. VASTEX has innovated many of the features found in conveyor ovens today from control methods,

modular features, air movements and belt tracking.

Your Vastex Infrared Dryer has been Factory tested and burned in for a period of 2-8 hours. All components

Safety

DB-II-30:

Main Unit: 465 lbs (210.9 kg)

Included Legs: 30 lbs (13.6 kg)