WPLLD Site Prep and Installation Guide Table of Contents

i

Table of Contents

1 Introduction

Contractor Certification Requirements ...........................................................................1-1

Related Manuals ............................................................................................................1-1

Safety Precautions .........................................................................................................1-1

Before You Begin ...........................................................................................................1-2

System Description ........................................................................................................1-2

2 Site Considerations

Stage II Vapor Recovery ................................................................................................2-1

Submersible Pumps (STPs) ...........................................................................................2-1

Piping Runs ...................................................................................................................2-1

Existing Check Valves ...................................................................................................2-1

Manifolded Product Lines ..............................................................................................2-1

Wire Length ...................................................................................................................2-1

Pump Power ..................................................................................................................2-1

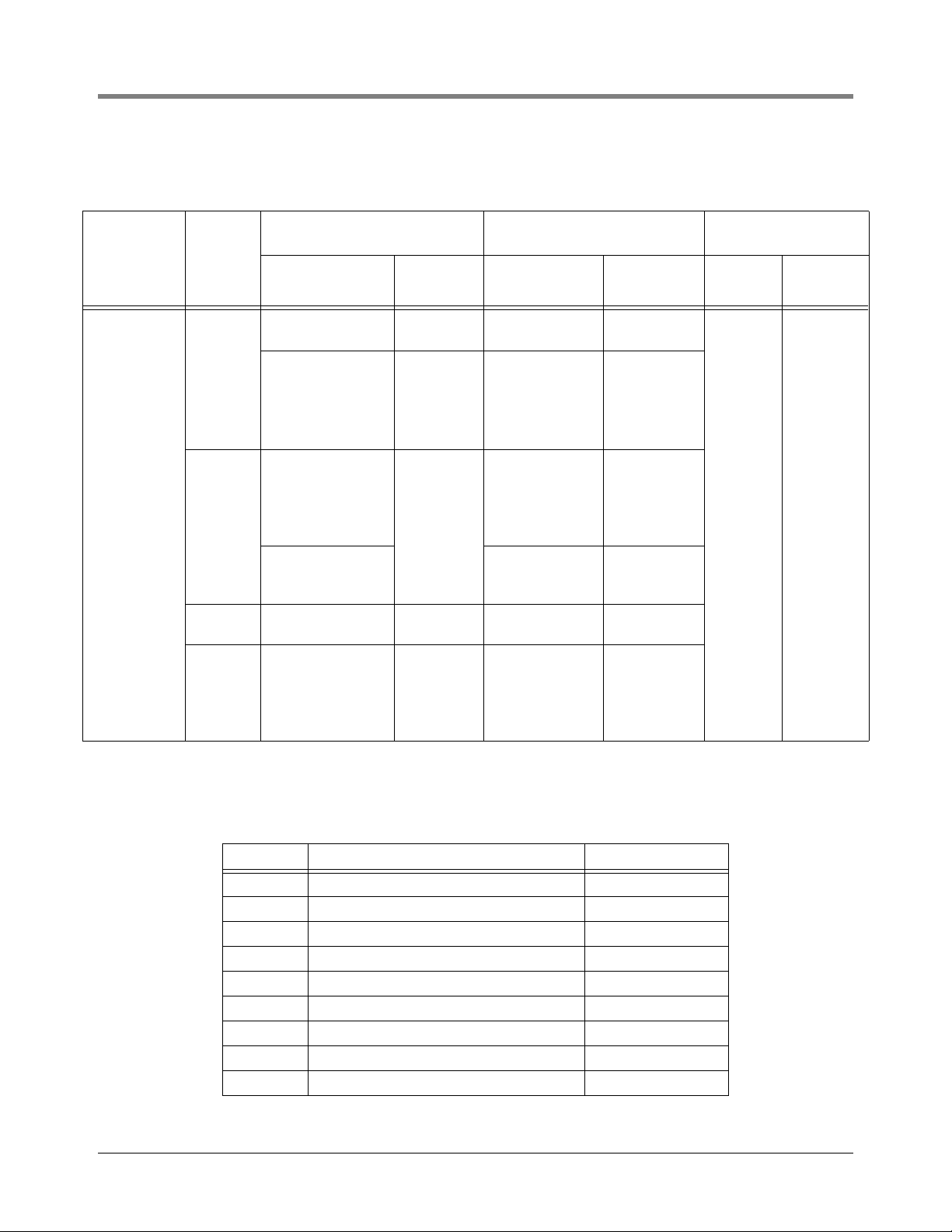

3 Running Conduit/Wiring for WPLLD System

WPLLD Controller Module .............................................................................................3-1

Pump Power Wiring...............................................................................................3-1

Pump Control Wiring .............................................................................................3-1

WPLLD AC Interface Module .........................................................................................3-1

Verifying WPLLD Communications Capability ...............................................................3-2

4 WPLLD System Installation

Red Jacket Pumps (Except Quantum and The Red Jacket) .........................................4-1

SwiftCheck Valve Installation ................................................................................4-1

Adjusting the Pressurstat Relief Pressure (for 3.0 gph testing only).....................4-3

Disabling the Functional Element (required for 0.2 & 0.1 gph testing)..................4-3

Transducer Installation..........................................................................................4-4

Red Jacket Quantum Pump (w/ and w/o SpikeCheck Valve Assy.) ..............................4-7

The Red Jacket Pump ...................................................................................................4-9

FE Petro Pumps ..........................................................................................................4-10

Transducer Installation........................................................................................4-10

Manifolded Product Line WPLLD Installation ...............................................................4-12

Dual Pumps in Single Tank.................................................................................4-12

Multiple Tanks with Manifolded Product Lines ....................................................4-13

WPLLD Installation with Stage II Vapor Recovery Systems ........................................4-14

Warning Tags ..............................................................................................................4-15

5 Connecting Console to Pump Wiring

General Wiring Practices ...............................................................................................5-1

Pump Control Wiring for Red Jacket and Other Pumps ................................................5-1

6 Checking the System

Setting the Signal Strength Jumper ...............................................................................6-1

Guidelines..............................................................................................................6-1

WPLLD System Checkout Procedure ............................................................................6-2

Pressure Offset......................................................................................................6-2

Venting The Line ...................................................................................................6-2