4

VEEDER-ROOT

82345

P

OP1

OP2

PGM RST

OPERATION

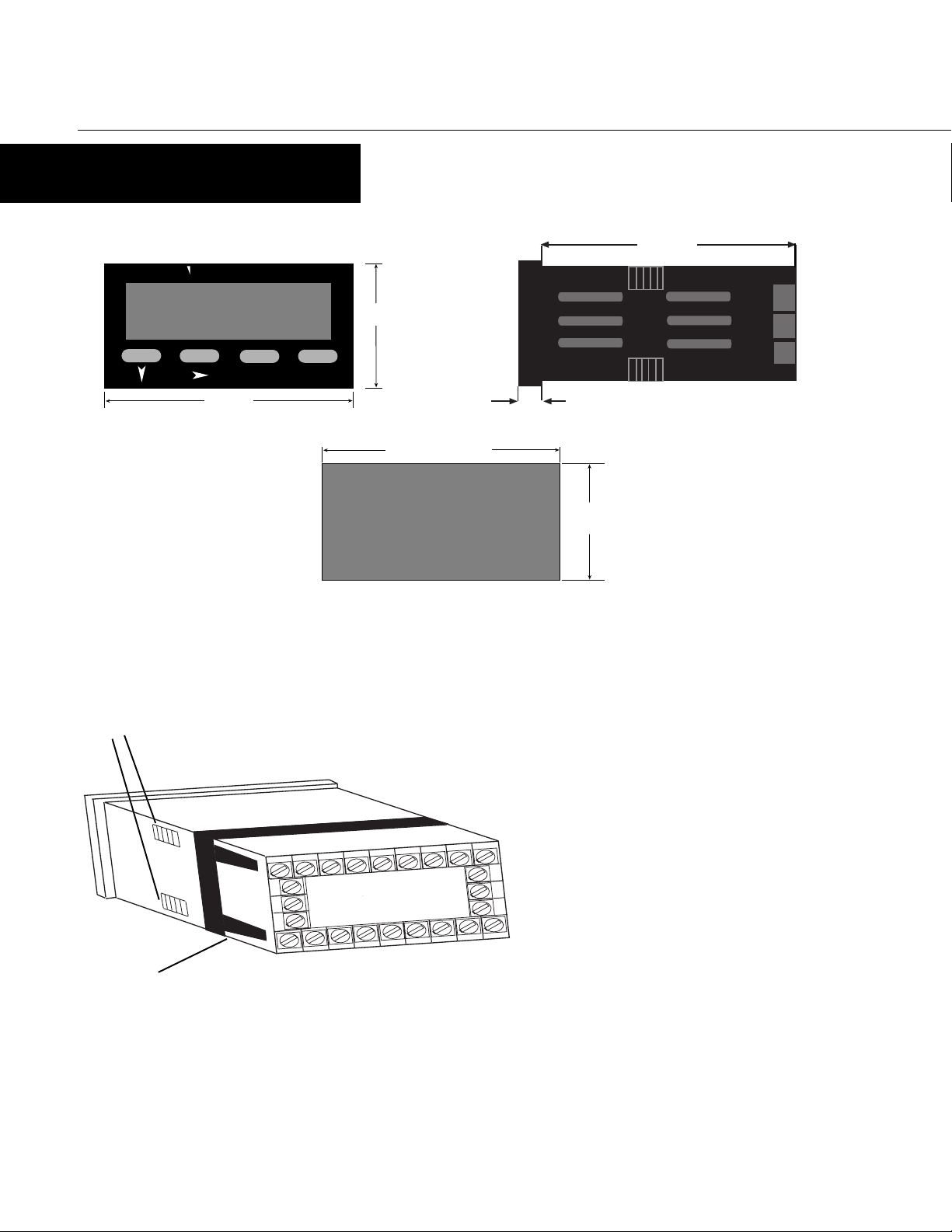

FRONT PANEL

Down Key Scroll Key Program Key Reset Key

Secondary Display

Scroll

Down InOperationMode: Usedineditoperationto decrement

thedigithighlightedbytheScrollkey.

InProgramMode: UsedinEditOperation to decrement

the digit highlightedby the Scrollkey, if thesettingis

anumerical value, or present the next in the series of

choicesforthatparameter.

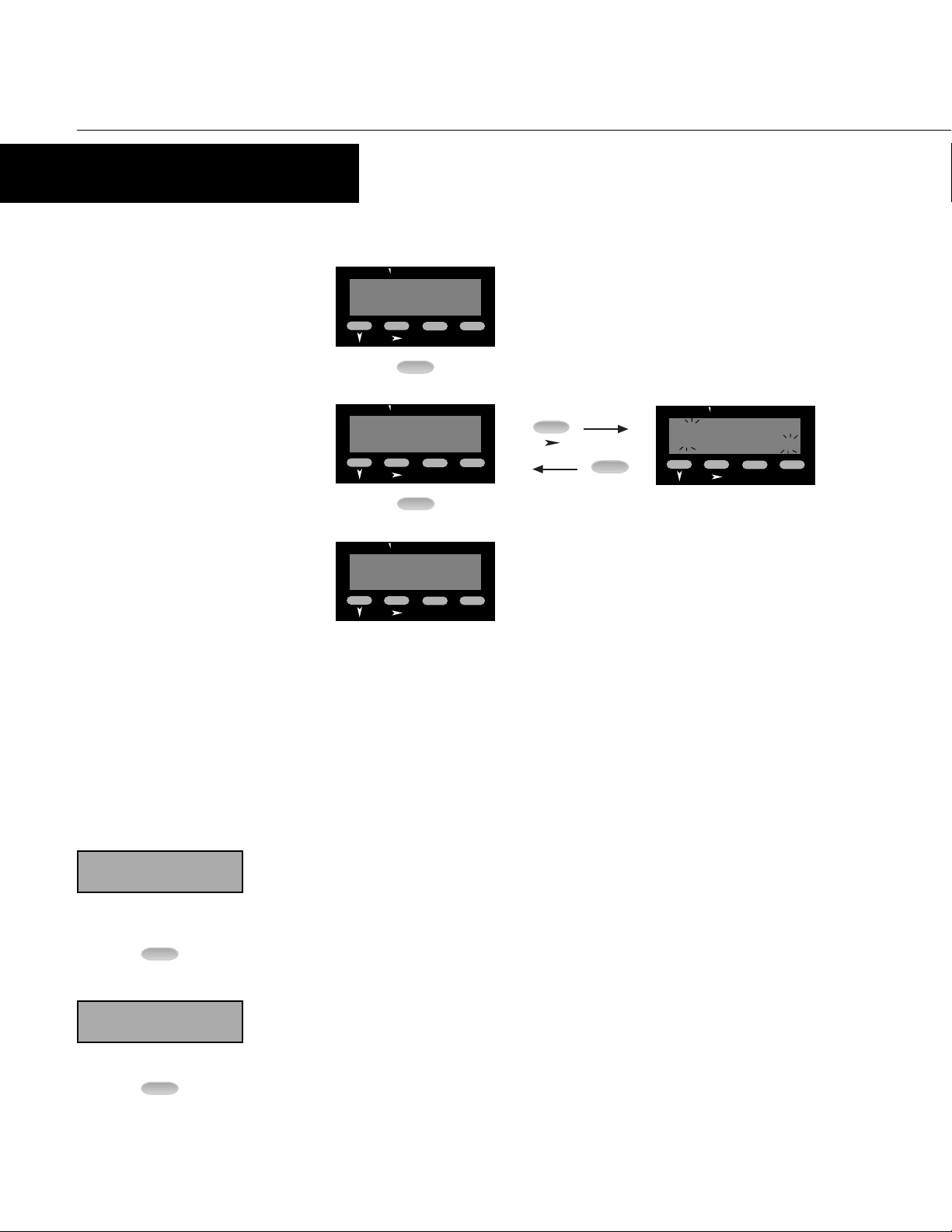

Program InOperationMode: Used tomove between the

parametersandtoenteraneditedpresetvalue.

Holding the key down for 3 seconds will cause the

unittoenterProgramMode.

InProgram Mode: Used to move from one parameter to

thenextandentertheeditedparametervalues.

Holding the key down for 3 seconds will cause the

unittoreturntoOperationMode.

InAllmodes: Movesthe unitinto Edit Operation,

whichisindicatedbytheleftmostdigitflashing.

Successive presses of the key are used to move to the

digit to be edited. Wrap around will occur from least

significantdigittomostsignificantdigit.

Reset InOperationMode: Resetsthecountvalue,batch

value,or background totalto zero (or to the preset in

countdownoperation). Parametermustbedisplayed

to be reset. This button can be disabled via the "Front

PanelResetEnable"parameterinProgramMode.

InProgramMode: Nofunction.

InAllmodes: Willabortan Edit Operation and return

thepreset/parametertoitspreviousvalue.

Down &

Scroll

together

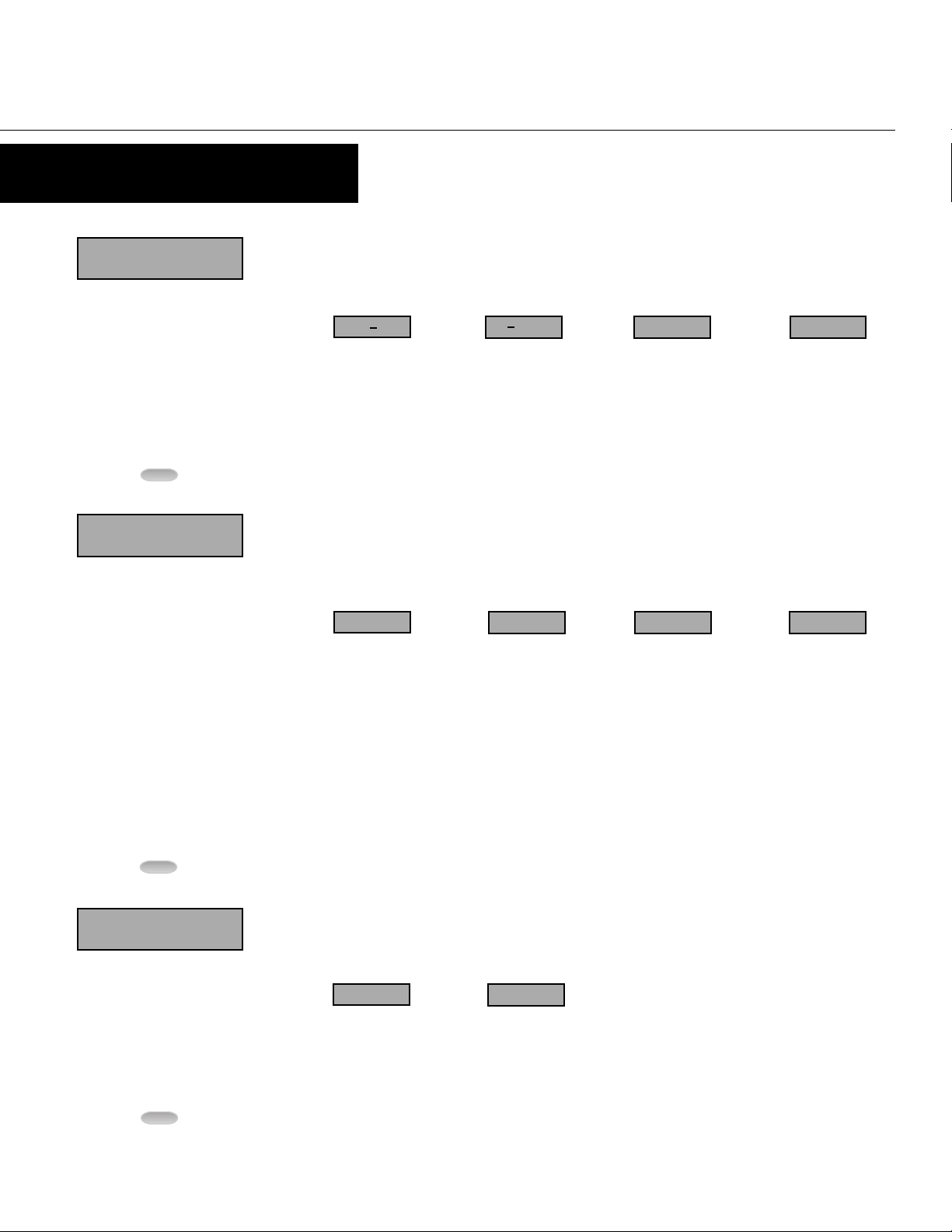

Key Primary InOperationMode: Defaultdisplayisthecountvalue.

Canbescrolledusing the programkey to displaythe

otherparameters. Ifthe"Help"functionisenabled,

thisdisplaywillfirstshowtheparameterdescription

for3 seconds(see page5 for example).

InProgramMode: Displaysthevalueorselectionfor

thecurrent parameter. If the "Help" function is

enabled,thisdisplaywillfirstshowtheparameter

descriptionfor3seconds(seepage6forexample).

Secondary InOperationMode: Indicatesalphabeticallywhether

Preset,BatchValue,BatchPreset,orBackgroundTotal

isbeing viewed on the primary display. This displayis

blankwhen CountValueisbeingshown.

InProgramMode: Providesa 1 digit alpha ornumeric

charactertoindicatewhichparametervalueisbeing

shownontheprimarydisplay.

Output

Indicators InOperationMode: OP1illuminateswhenOutput1 is

active. OP2illuminateswhenOutput2is active.

InProgramMode: Nofunction.

Display Functions

Key Functions

Function Display Function

Output Indicators

Primary Display