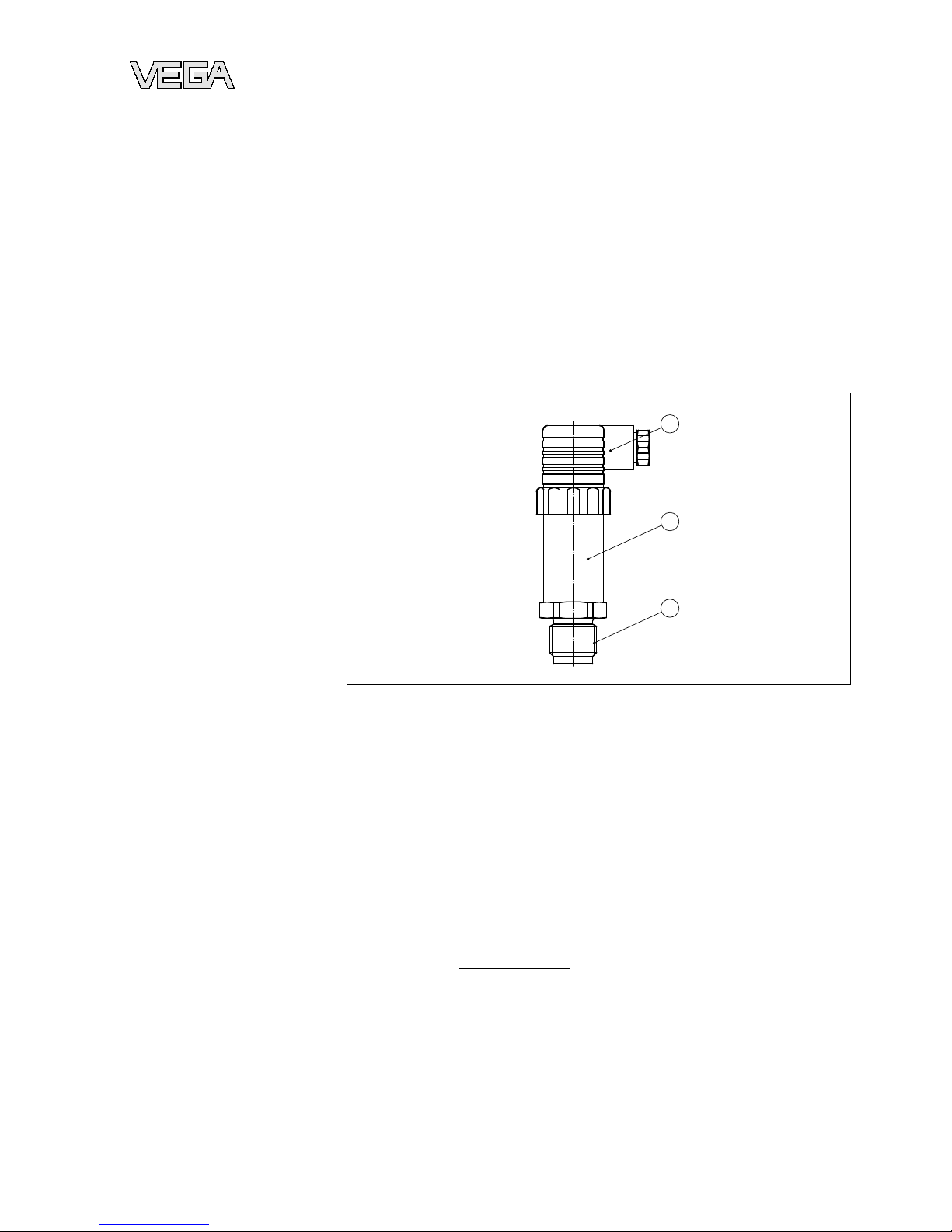

3.2Principle of operation

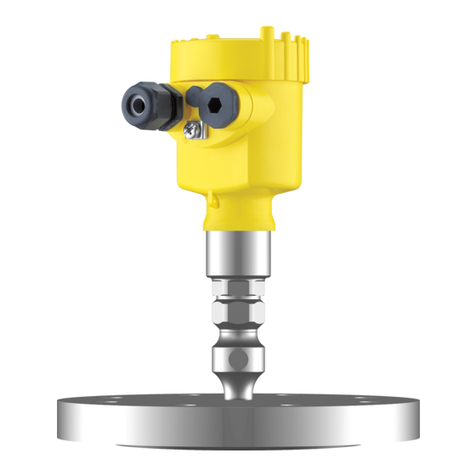

VEGABAR 17 is a pressure transmitter for measurement of gauge

pressure,absolute pressure or vacuum.Measured products are

gases,vapours and liquids.The front flush versions are also suitable

for use in viscous or contaminated products.

The process pressure acts on the sensor element via the stainless

steel diaphragm.The process pressure causes a resistance change

which is converted into a corresponding output signal and outputted as

measured value.1)

Two-wire electronics 4…20 mAfor power supply and measured

value transmission on the same cable.

3.3Operation

VEGABAR 17 has no adjustment options.However,two potentiom-

eters are integrated for the recalibration of zero and span.

3.4Packaging,transport and storage

Your instrument was protected by packaging during transport.Its

capacity to handle normal loads during transport is assured by a test

according to DIN EN 24180.

The packaging of standard instruments consists of environment-

friendly,recyclable cardboard.For special versions,PE foam or PE foil

is also used.Dispose of the packaging material via specialised

recycling companies.

Instruments for oxygen applications are sealed in PE foil and provided

with a label "Oxygen!Use no Oil".Remove this foil just before

mounting the instrument!See instruction under "Mounting".

Transport must be carried out under consideration of the notes on the

transport packaging.Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt.Ascertained transit damage or

concealed defects must be appropriately dealt with.

Up to the time of installation,the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

1)Measuring ranges up to 16 bar:piezoresistive sensor element with internal

transmission liquid,with measuring ranges up to 25 bar:Strain gauge

(DMS)sensor element on the rear of the stainless steel diaphragm (dry).

Area of application

Functional principle

Voltage supply

Packaging

Transport

Transport inspection

Storage

8VEGABAR 17

3Product description

27636-EN-081029