VEGACOM 557 - without protocol 7

Adjustment

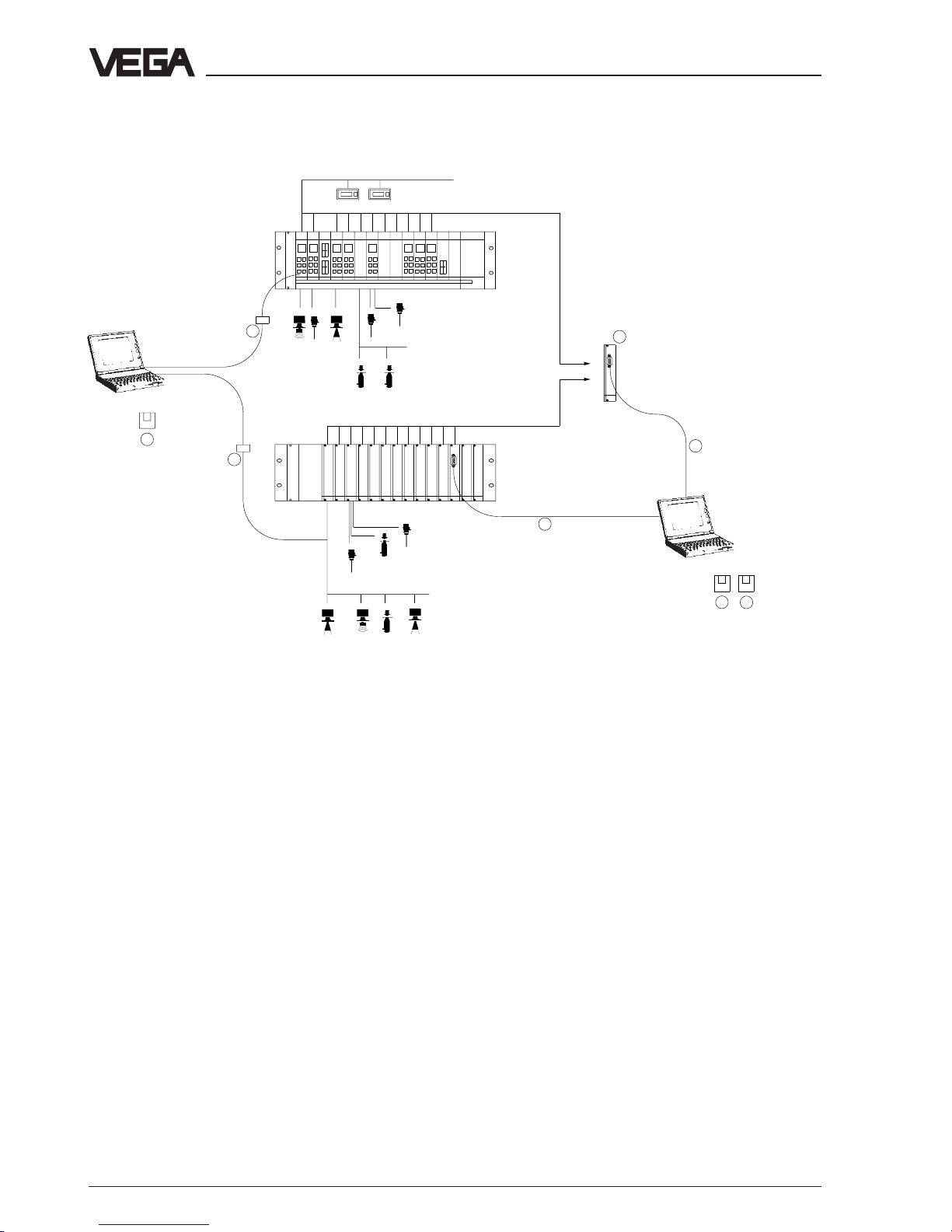

2.2 Visualisation

With the VISUAL VEGA (VV) visualisation

program measured values of VEGA-

processing systems can be shown graphi-

cally or in tabular form.

Measured value and status information are

transmitted via the interface of VEGACOM

557 or the VEGALOG CPU-card to the PC.

For a better survey, these measurement

loops can be composed in groups. A direct

comparison of several measurement loops is

therefore possible. In addition level and fault

signals are displayed.

It is also possible to save the measured

values on the PC. The cycle and the saving

period can be adjusted depending on the

requirement. The history data can be dis-

played graphically or in tabular form. The

conversion of the data in ASCII-format en-

sures the data exchange with other pro-

grams.

2.3 Remote parameter adjustment

The PC with the VEGA Visual Operating

(VVO) adjustment program can also be used

for remote parameter adjustment.

The Visual VEGA (VV) program enables the

remote visualisation.

Then do not connect the PC with the RS-232-

cable directly to the PC; but via modems and

the telephone line. Further information is stated

in the operating instructions remote parameter

adjustment.

2.1 Configuration and parameter ad-

justment of connected measur-

ing systems

An additional function of VEGACOM 557 is

the adjustment of the connected measuring

system. The adjustment is made via a PC by

means of the VEGA Visual Operating (VVO)

adjustment software . The PC is connected

via an interlink cable to the 9-pole SUB-D-

plug in the front plate of VEGACOM 557.

The VEGA-adjustment concept includes the

convenient configuration and parameter

adjustment of the measuring system or of the

sensors with the following instruments:

- VEGAMET series 500/600 signal conditioning

instruments

- VEGALOG 571 processing system

- hydrostatic pressure transmitters

- ultrasonic/radar sensors

- capacitive electrodes

The adjustment is menu-guided and window

orientated. The procedure is always the

same regardless of, whether a radar sensor,

several connected signal conditioning instru-

ments or a VEGALOG need to be adjusted

via PC.

The configuration of the measuring system

comprises, depending on the connected

instruments, e.g. the determination of the

output functions or the configuration of indi-

vidual inputs or outputs. The user oriented

creation of measurement loops is supported

by graphic means, such as for example

vessel drawings and pictographs which

adapt due to the choice acc. to the actual

conditions and options.

Due to the graphic support, complex param-

eter adjustments such as for example the

adjustment of a linearisation curve by means

of index markers can also be easily carried

out.