2

Contents

VEGACAP 66 • - contactless electronic switch

30021-EN-160331

Contents

1 About this document

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 6

2.6 CE conformity................................................................................................................... 6

2.7 Safety instructions for Ex areas ........................................................................................ 6

2.8 Environmental instructions ............................................................................................... 6

3 Product description

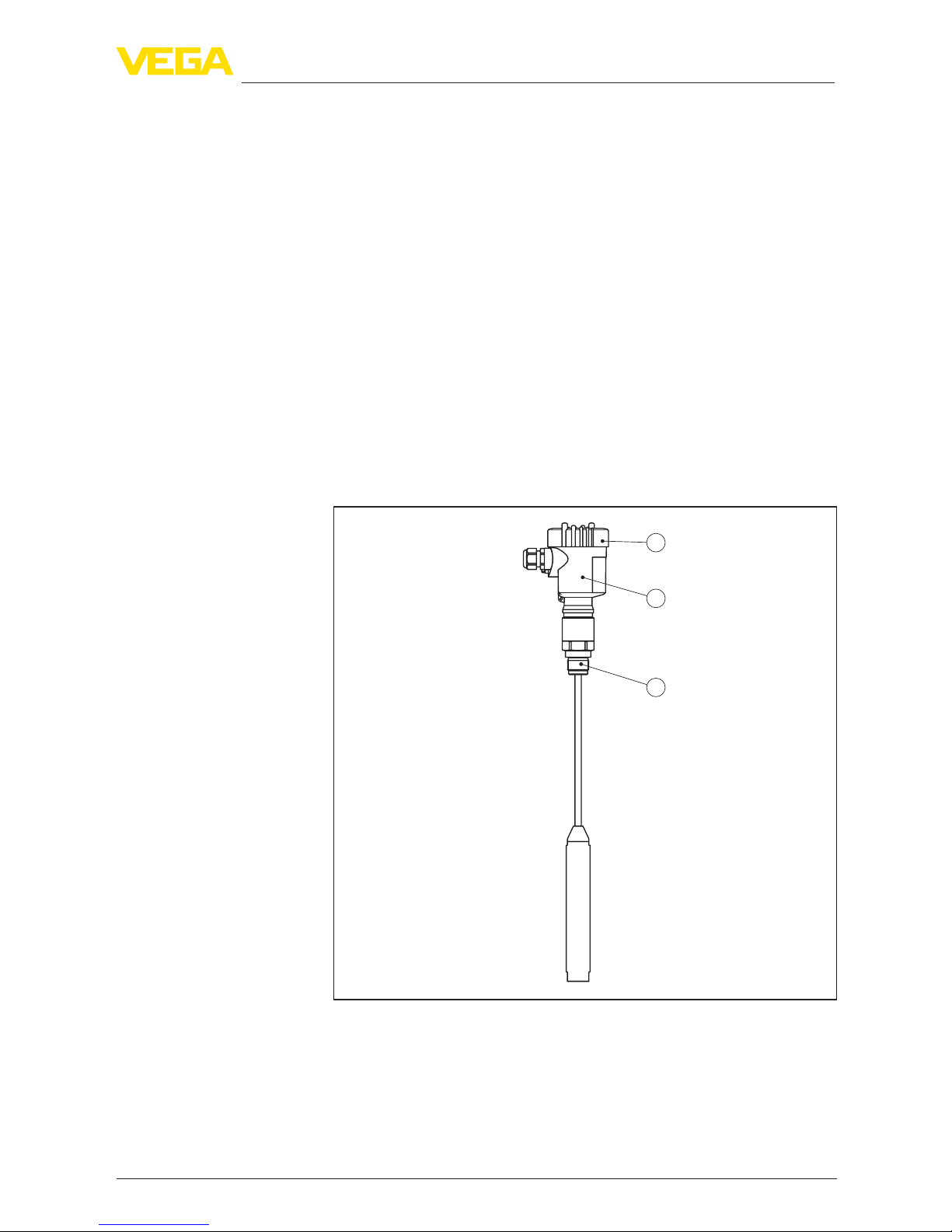

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Operation ......................................................................................................................... 9

3.4 Packaging, transport and storage..................................................................................... 9

3.5 Accessories and replacement parts ............................................................................... 10

4 Mounting

4.1 General instructions ....................................................................................................... 11

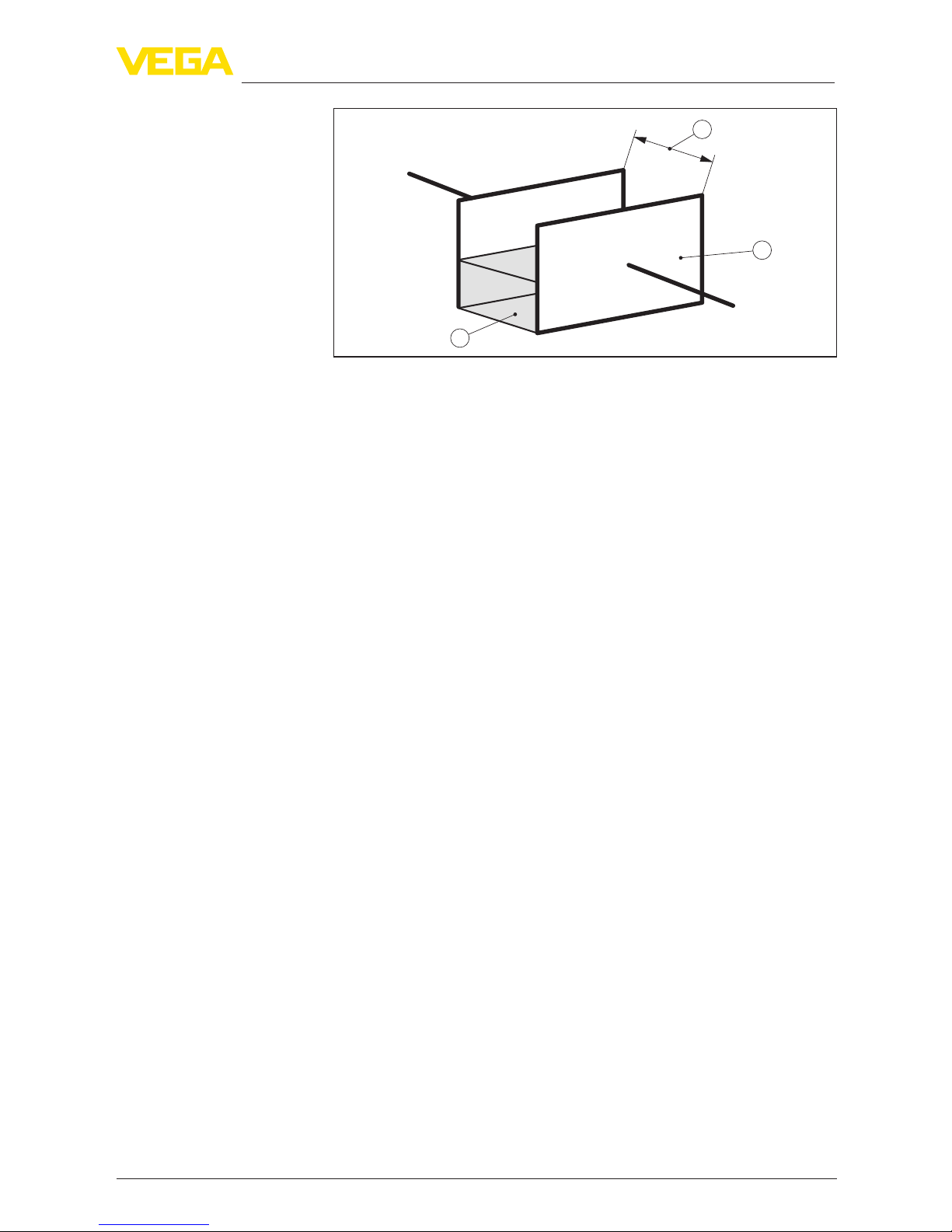

4.2 Mounting instructions ..................................................................................................... 12

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 16

5.2 Connection procedure.................................................................................................... 16

5.3 Wiring plan, single chamber housing.............................................................................. 17

6 Setup

6.1 General information........................................................................................................ 20

6.2 Adjustment elements...................................................................................................... 20

6.3 Function table................................................................................................................. 22

7 Maintenanceandfaultrectication

7.1 Maintenance .................................................................................................................. 23

7.2 Rectify faults................................................................................................................... 23

7.3 Exchange of the electronics module............................................................................... 25

7.4 How to proceed if a repair is necessary.......................................................................... 27

8 Dismount

8.1 Dismounting steps.......................................................................................................... 28

8.2 Disposal ......................................................................................................................... 28

9 Supplement

9.1 Technical data ................................................................................................................ 29

9.2 Dimensions .................................................................................................................... 32

9.3 Industrial property rights................................................................................................. 35

9.4 Trademark ...................................................................................................................... 35