Veit Brisay BRI-7570/101 FPD User manual

VEIT Garment & Textile

Technologies GmbH & Co.

Valdorfer Straße 100

D-32602 Vlotho / Germany

Tel.: ++49 0) 57 33 / 87 13-0

Fax: ++49 0) 57 33 / 87 13-45

e-mail: info@veit-kannegiesser.de

Internet: www.veit-kannegiesser.com

Ein Unternehmen der Veit-Gruppe

GB

USA

Translation of Instruction anual

Variant

Machine no.:

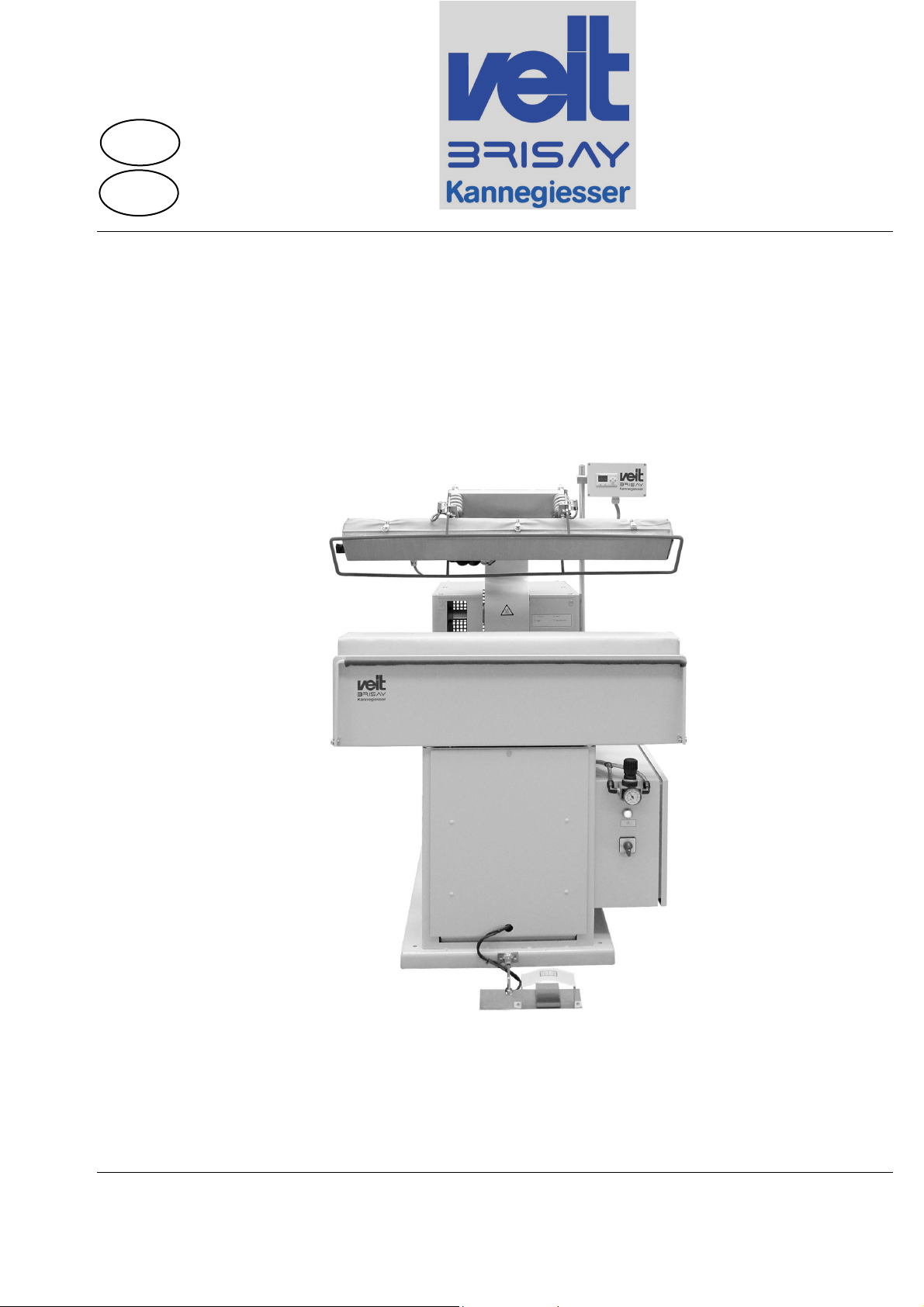

BRI-7570/101 FPD

FRONT PLACKET DEVICE

Translation

In case of the machine being delivered in EEA countries, the operating instructions must be

translated into the language of the country of destination. Should the translation reveal incon-

sistencies, the user is obliged to consult the original operating instructions German) or to con-

tact the manufacturer.

Should the machine be sold and delivered to another EEA country at a later point in time, the

operating instructions have to be translated into the language of the relevant country of destina-

tion.

Copyright

This document as well as the information contained in it are protected by copyright and must

not be copied as a whole or in parts or made available to third parties without the written con-

sent of the editor.

© Copyright Brisay-Maschinen GmbH, 63762 Grossostheim-Ringheim, Germany

Intended use

14.02.11 BRI-7570_020 i

Table of contents

1. Intended use ...................................................................... 1

1.1. Description of the machine ......................................... 2

1.2. Function ...................................................................... 3

1.3. Technical data............................................................. 4

1.4. Scope of delivery ........................................................ 5

2. Safety................................................................................. 7

2.1. Warning symbols and danger signs........................... 7

2.1.1. Designation of the machine.................................... 8

2.2. Safety standards ......................................................... 9

2.3. Built-in safety systems .............................................. 10

2.4. Safety measures ....................................................... 12

2.5. Safety tests ............................................................... 13

3. Potential dangers ............................................................. 15

3.1. Dangerous areas of the machine.............................. 16

3.2. Duties of the operating company .............................. 17

3.3. Operating and maintenance staff.............................. 18

3.4. Disconnect procedures ............................................. 19

4. Transport and packing ..................................................... 21

4.1. Delivery ..................................................................... 21

4.2. Unloading and transport to the place of installation . 22

4.2.1. Lifting points ......................................................... 26

5. Installation........................................................................ 27

5.1. Setting-up.................................................................. 27

5.2. Installation................................................................. 29

5.3. Commissioning ......................................................... 31

5.3.1. Setting instructions suction valve (option) ............ 32

6. Operation ......................................................................... 33

6.1. Operator’s controls and displays............................... 33

Table of contents

ii BRI-7570_020 14.02.11

6.1.1. Switch cabinet.......................................................34

6.1.2. Process control .....................................................35

6.1.3. Pedal strip.............................................................38

6.2. Starting the machine .................................................39

6.3. Pressing in automatic operation ................................39

6.4. Switching off the machine .........................................40

7. Maintenance .....................................................................41

7.1. Changing of pressing covers .....................................41

7.1.1. Changing cover of lower buck...............................43

7.1.2. Changing cover of heating plate ...........................44

8. Maintenance / Cleaning...................................................45

8.1. Cleaning ....................................................................47

8.2. Maintenance and inspection table .............................48

8.2.1. Machine checks ....................................................49

9. Defects, Cause, Elimination .............................................51

9.1. Trouble shooting via process control.........................54

10. Emergency....................................................................55

11. Dismantling / Disposal..................................................57

12. Spare parts lists ............................................................59

12.1. Cover material........................................................61

13. EC declaration of conformity.........................................63

Intended use

14.02.11 BRI-7570_020 1

1. INTENDED USE

This machine has been developed, designed and built for

industrial and commercial use only.

The front placket device BRI-7570 FDP glues front plackets of

shirts and blouses by applying heat and pressure.

Note The machine is intended for the working of textiles only.

The

manufacturer shall not assume any responsibility for

modifications and changes which are not stated in the

declaration of conformity.

If the place of installation does not comply with the intended

use, reb

uilding measures must be taken to obtain a higher

level of protection (see chapter 1.3, Technical data).

This machine serves the above-mentioned purpose only.

Any

other or further use as well as any rebuilding or retrofitting of

the machine without the

written consent of the manufacturer

will be considered as non-compliance with the intended use.

The manufacturer shall not be liable for damages caused by

such use. The user alone bears the risk.

This also applies to the installation and setting-up of sa

fety

equipment and valves as well as to any changes in the

supporting parts of the machine.

The intended use also comprises the observance of operating

instructions and compliance with the inspection and

maintenance intervals prescribed by BRISAY.

Table of contents

Other Veit Brisay Industrial Equipment manuals