10

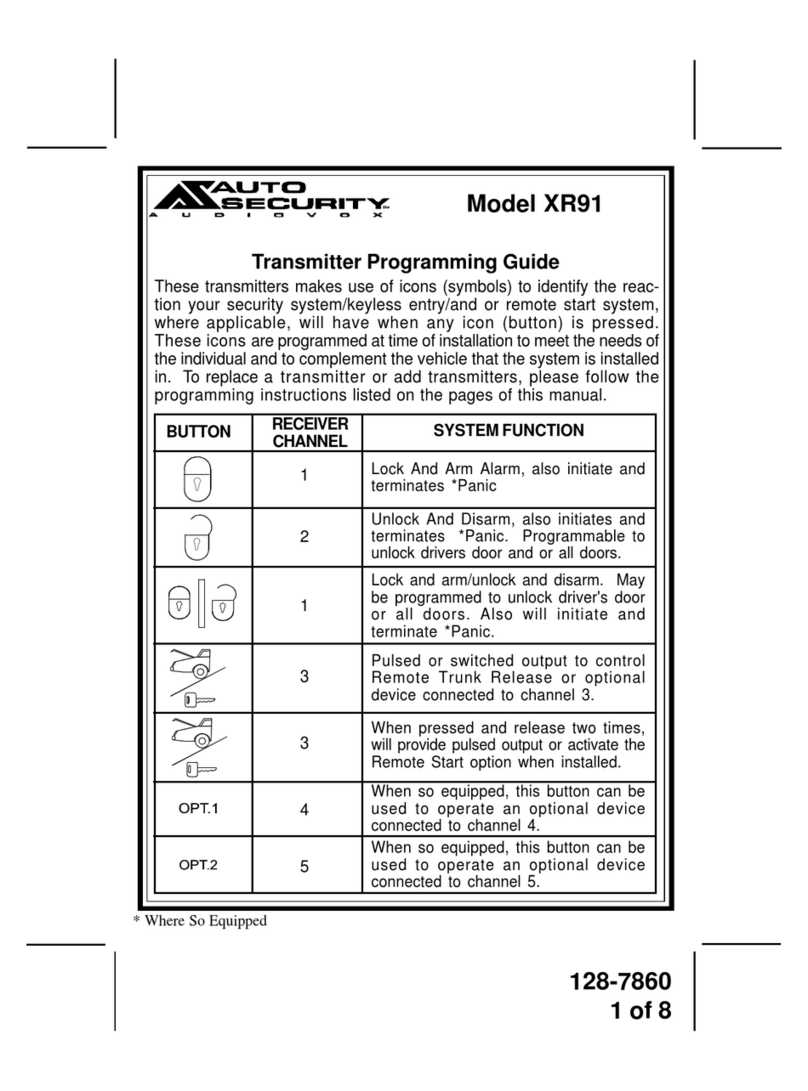

(C) Construction of the main PCB 3511

J

1. Jumperwire

ZD1 : 2V4

ZD2 : 5V1

ZD3 : 18V

ZD4 : 18V

ZD5 : 18V

3.Zener diode. Check the polarity!

D1 : 1N4148

D2 : 1N4148

D3 : 1N4148

D4 : 1N4148

D5 : 1N4148

D6 : 1N4148

D7 : 1N4000 … 1N4007

D8 : 1N4000 … 1N4007

D9 : 1N4000 … 1N4007

D10 : 1N4000 … 1N4007

D11 : 1N4000 … 1N4007

D12 : 1N4000 … 1N4007

2. Diodes (Check the polarity)

CATHODE

D...

CATHODE

ZD...

R1 : 100K (1 - 0 - 0 - 3 - 1)

R2 : 100K (1 - 0 - 0 - 3 - 1)

R3 : 100K (1 - 0 - 0 - 3 - 1)

4. Resistors (check the color code)

R...

R4 : 100K (1 - 0 - 0 - 3 - 1)

R5 : 10 (1 - 0 - 0 - B)

R6 : 220 (2 - 2 - 1 - B)

R7 : 4K7 (4 - 7 - 2 - B)

R8 : 4K7 (4 - 7 - 2 - B)

R9 : 4K7 (4 - 7 - 2 - B)

R10 : 4K7 (4 - 7 - 2 - B)

R11 : 1K (1 - 0 - 2 - B)

R12 : 1K (1 - 0 - 2 - B)

R13 : 1K (1 - 0 - 2 - B)

R14 : 1K (1 - 0 - 2 - B)

R15 : 1K (1 - 0 - 2 - B)

R16 : 1K (1 - 0 - 2 - B)

R17 : 1K (1 - 0 - 2 - B)

R18 : 1K (1 - 0 - 2 - B)

R19 : 1K (1 - 0 - 2 - B)

R20 : 47K (4 - 7 - 3 - B)

R21 : 47K (4 - 7 - 3 - B)

R22 : 47K (4 - 7 - 3 - B)

R23 : 47K (4 - 7 - 3 - B)

R24 : 47K (4 - 7 - 3 - B)

R25 : 47K (4 - 7 - 3 - B)

R26 : 47K (4 - 7 - 3 - B)

R27 : 47K (4 - 7 - 3 - B)

R28 : 47K (4 - 7 - 3 - B)

R29 : 10K (1 - 0 - 3 - B)

R30 : 10K (1 - 0 - 3 - B)

R31 : 10K (1 - 0 - 3 - B)

R32 : 10K (1 - 0 - 3 - B)

R33 : 10K (1 - 0 - 3 - B)

R34 : 10K (1 - 0 - 3 - B)

R35 : 10K (1 - 0 - 3 - B)

R36 : 10K (1 - 0 - 3 - B)

R37 : 10K (1 - 0 - 3 - B)

R38 : 10K (1 - 0 - 3 - B)

R39 : 10K (1 - 0 - 3 - B)

R40 : 10K (1 - 0 - 3 - B)

R41 : 10K (1 - 0 - 3 - B)

R42 : 10K (1 - 0 - 3 - B)

R43 : 10K (1 - 0 - 3 - B)

R44 : 10K (1 - 0 - 3 - B)

R45 : 100K (1 - 0 - 4 - B)

R46 : 100K (1 - 0 - 4 - B)

Construction