2

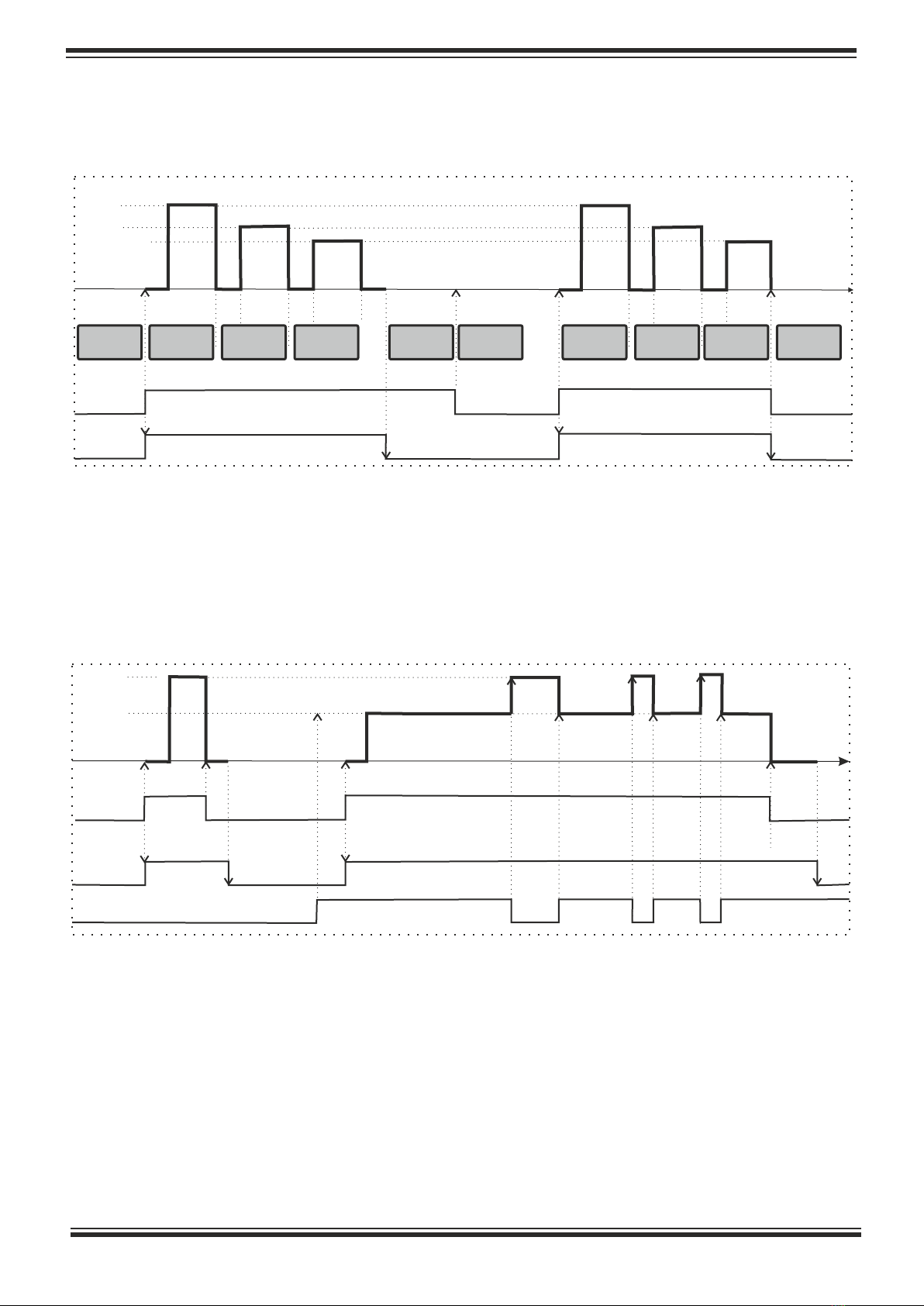

The controller can work in a direct mode of continuous welding while user

can correct the welding current by the arrow keys.

In working state with digital input off, the display will read ‘---, meaning that

the controller is ready to start a welding. In settings state the user can set by the

arrow keys the output power (0-100) of the welding current or different

parameters.

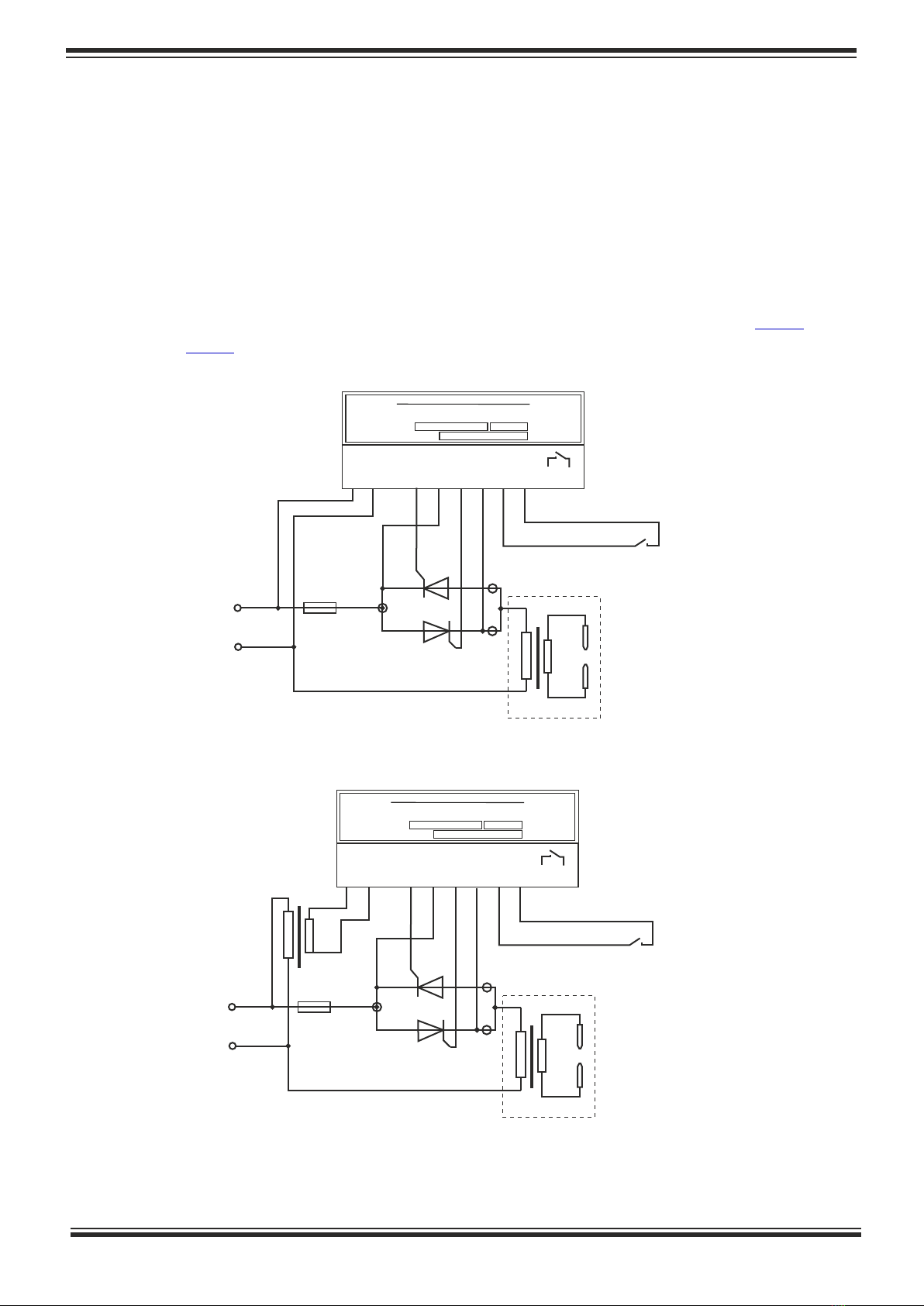

PCN101ZP power controller is used to regulate the phase angle of AC

loads, such as spot welding machines, both single or two-phase. When used with

two-phase loads ( ), a phase matching transformer 400/230V is needed, Fig.6

unless it is not provided in the controlled device. Without such a transformer as a

power supply to PCN101ZP, there will be a 30 degrees phase shift between

controller and loads, thus real control will not be possible.

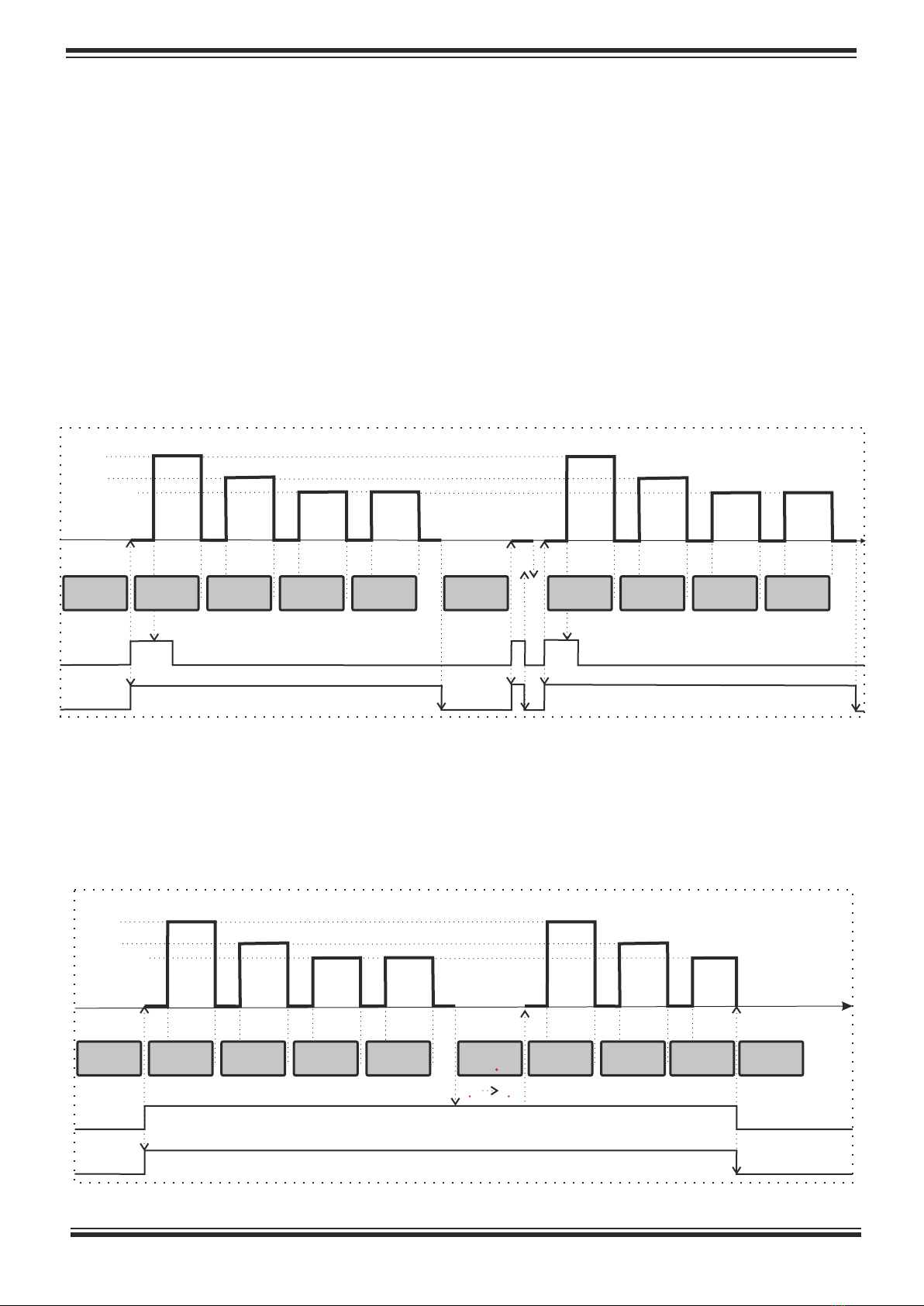

Multi-spark welding is implemented in order to achieve the best quality of

welding, especially for rounded items.

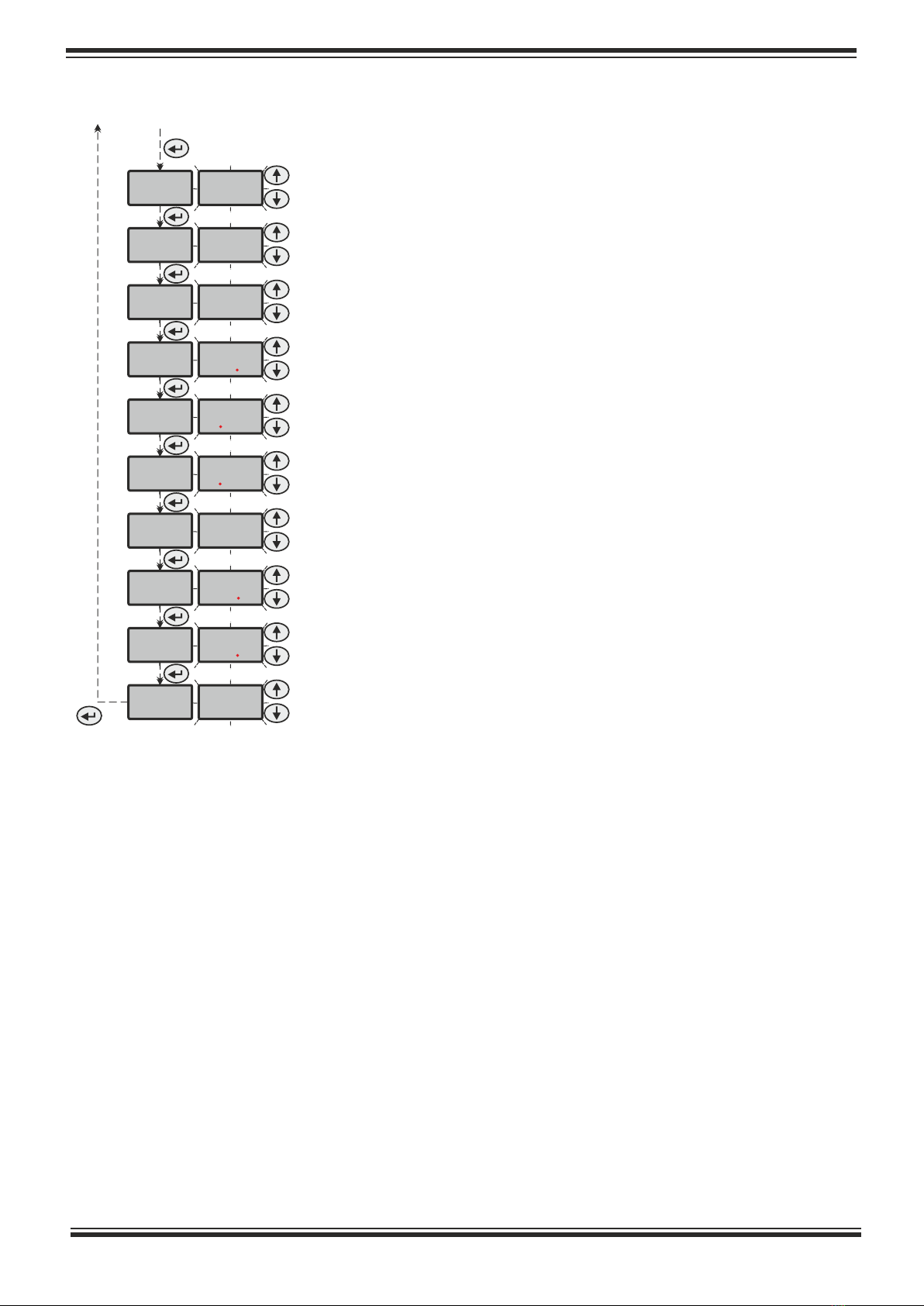

Five independent timers are provided to facilitate the process of welding:

pressing time (toF), weld time (ton), pause between multiple sparks (tP), cooling

time (tE) and delay time between welds (td) for repetitive welding only.

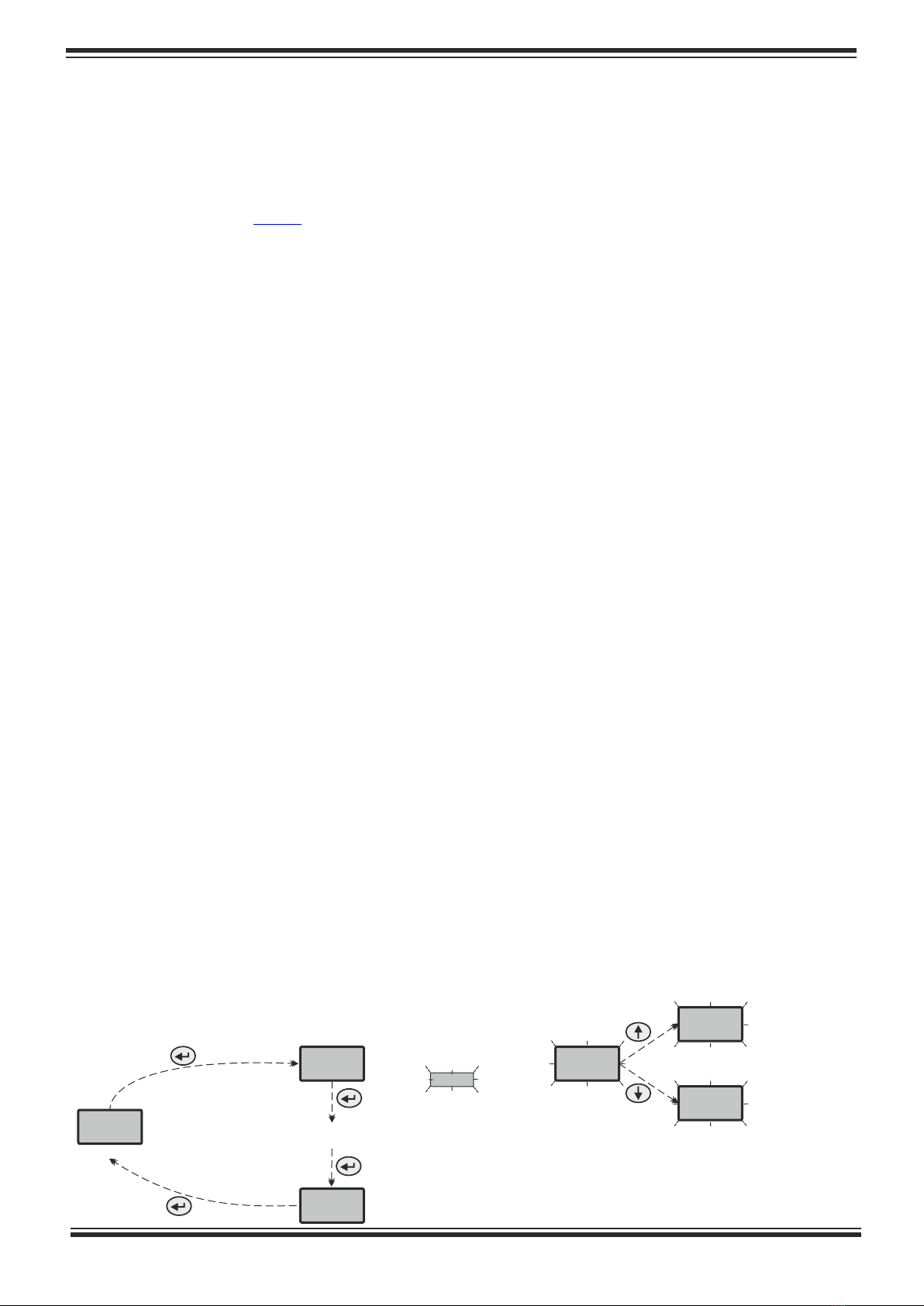

The controller’s display can switch between the following two states:

working and settings.

The output power, regulated by the PCN101ZP, is divided to 100 units

(percentage of the full power). The value of 0 means that the output of the

controller is off, whereas 100 means that it will transmit the full input power.

Introduction

Display of the controller

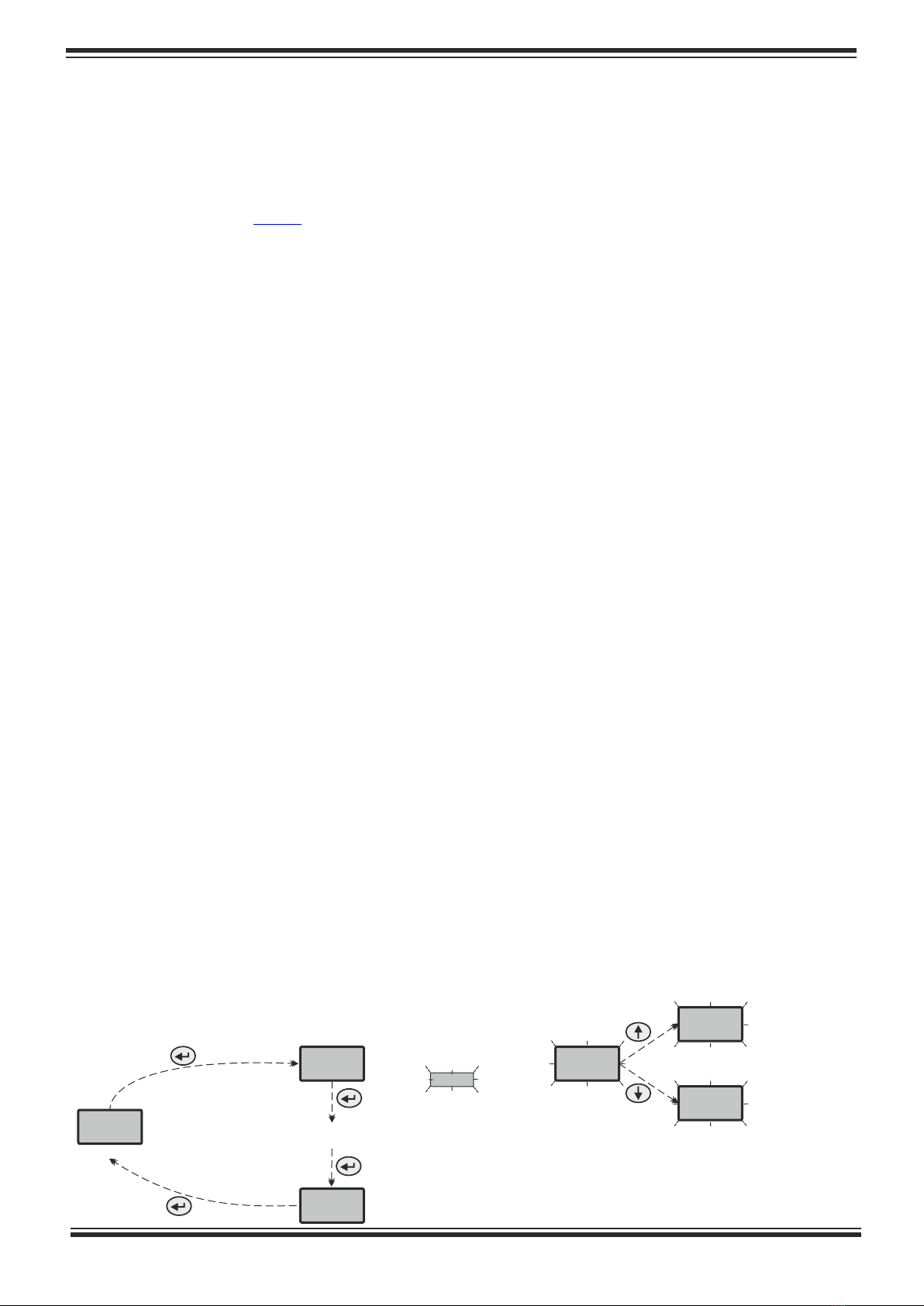

The ( ) button is used to switch between these two states. When in settings

8

state, the display will flash a mnemonic message with the parameter to be

changed by the user:

---

SP

Sb

70

69

71

parameter’s mnemonics

followed by parameter’s value

appear in flashing mode

after the last parameter

back to working state

navigate throughout

all parameters...

the value of the selected parameter

can be changed by arrow keys

Working state

to settings state