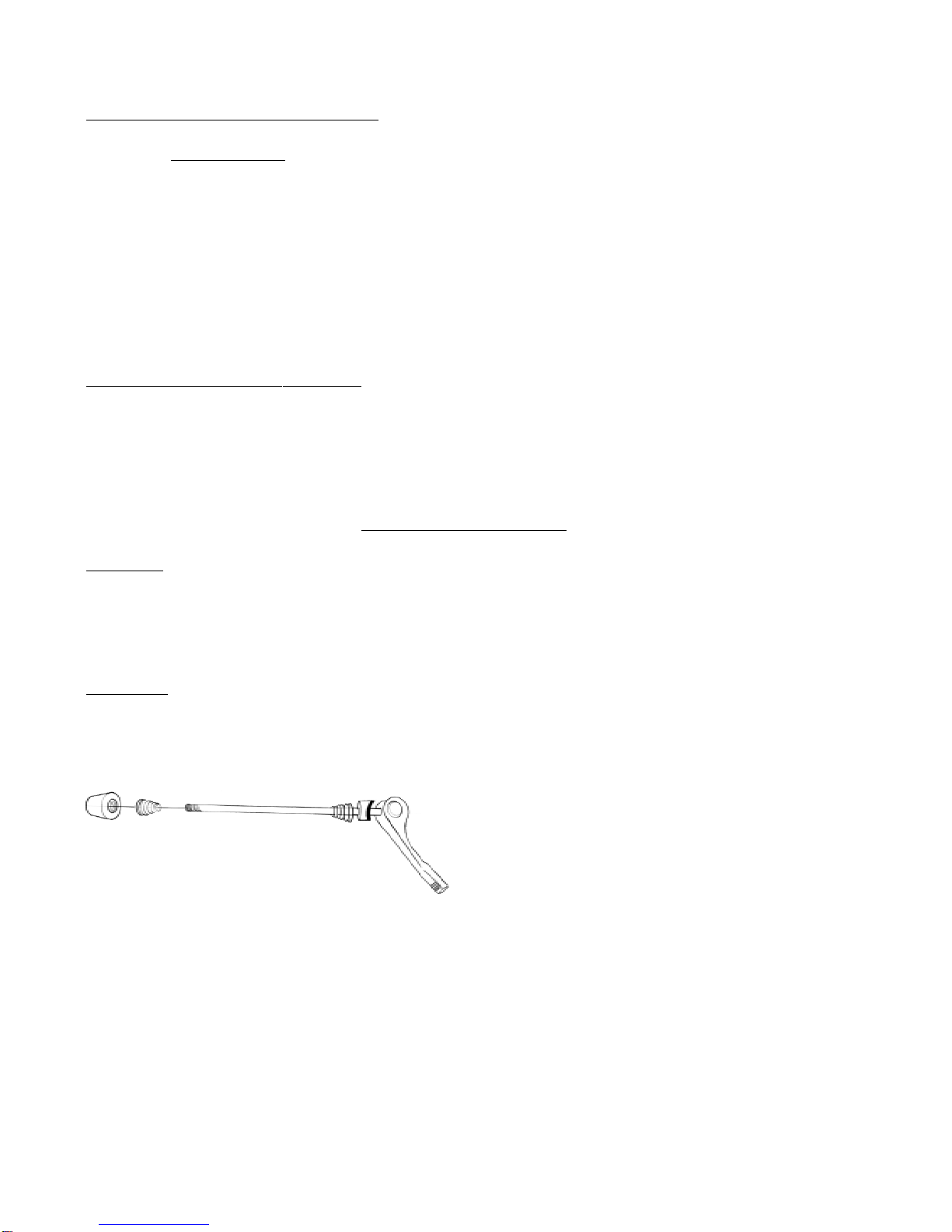

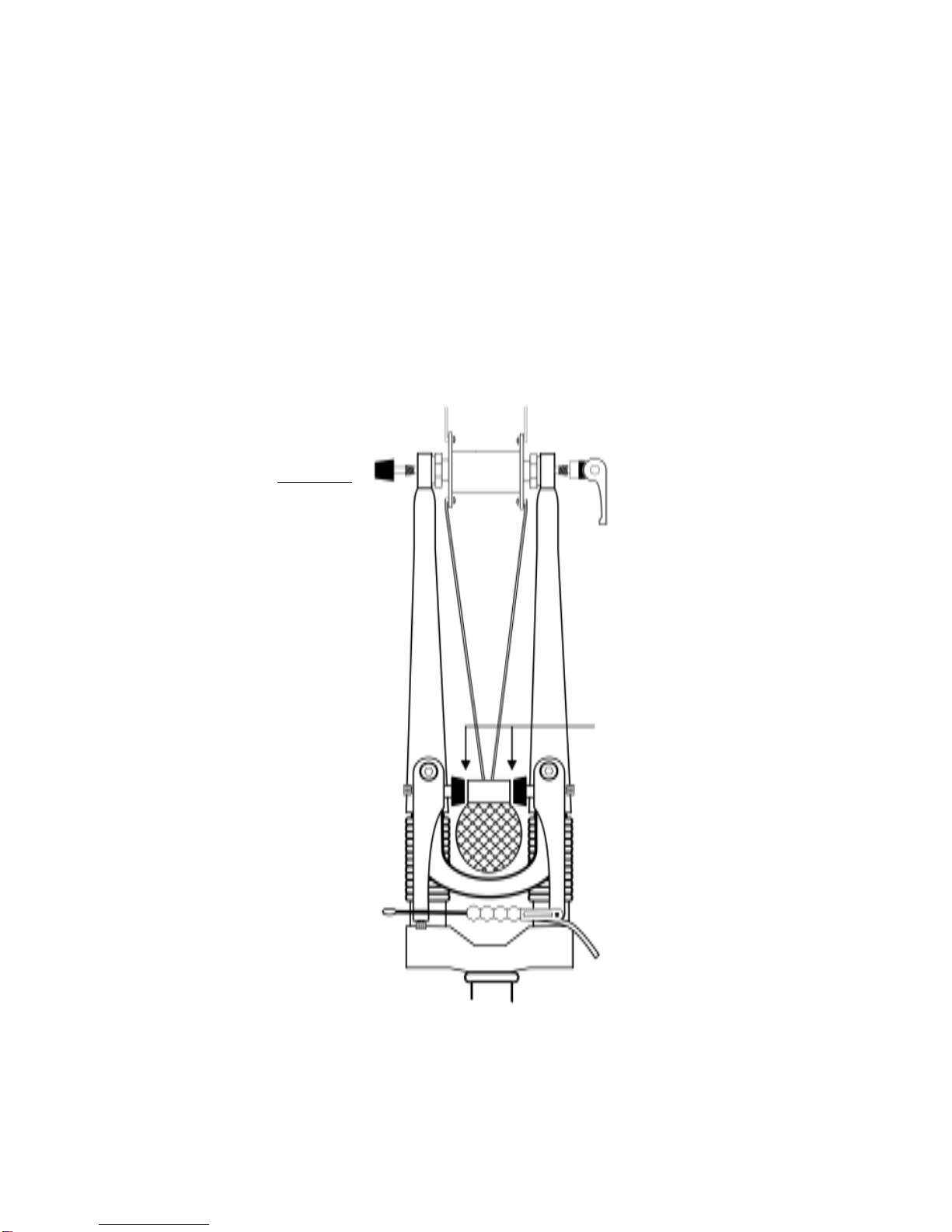

Tension Adjusting Nut Spring Spring

Lever

FIG. 13

STEP 11: FRONT WHEEL QUICK RELEASE

In this step you will secure the Front Wheel using the Front Wheel Quick Release.

IMPORTANT: Before doing this, read the following as a thorough understanding of the Front

Wheel Quick Release system is necessary for proper operation and safety.

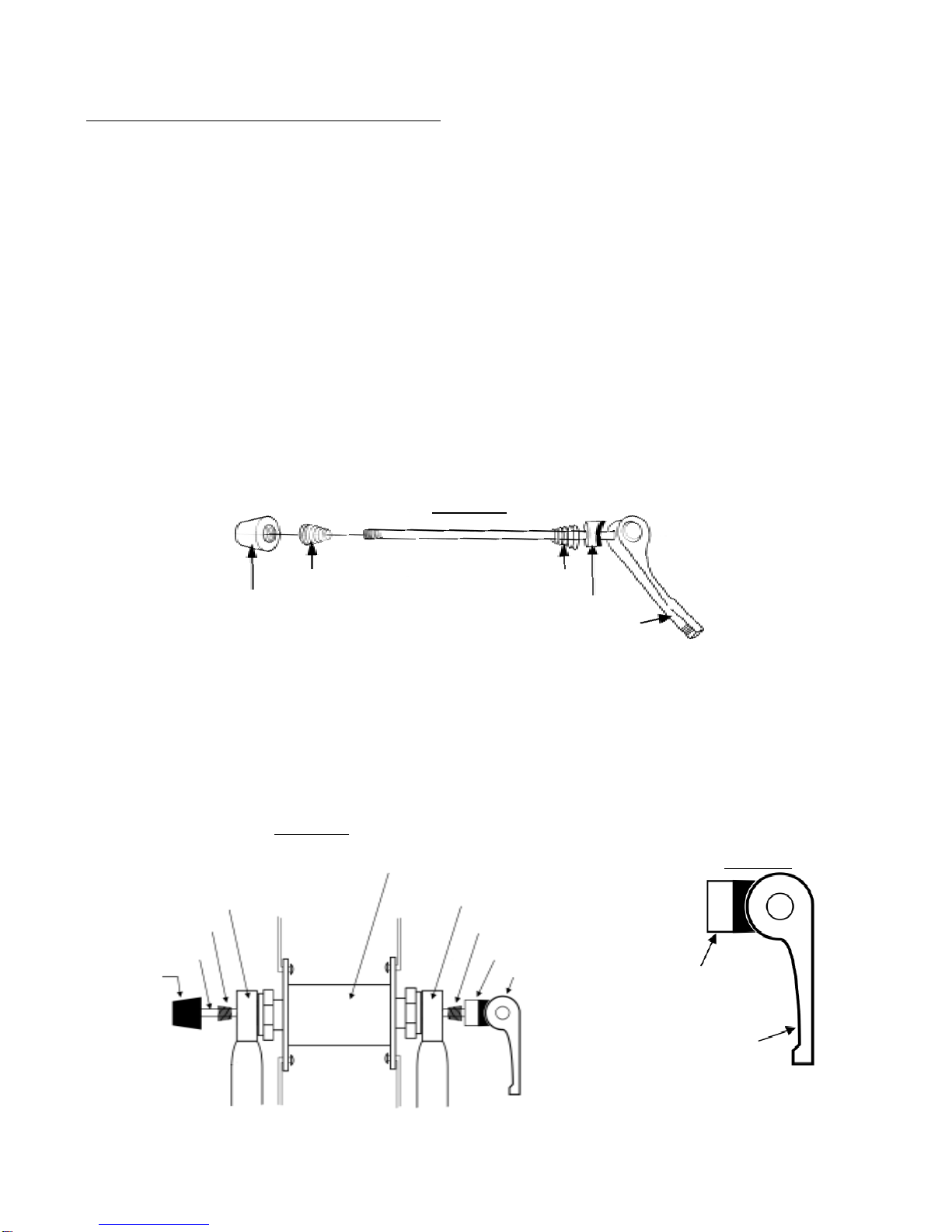

While it may look like a long bolt with a simple lever and nut on the ends, the Front Wheel Quick

Release uses an adjustable Lever and Cam on a skewer to secure the bike’s Front Wheel to the Fork.

Due to its Quick Release action and adjustable nature it is critical that you understand how the Quick

Release lever and cam work to insure your safety by proper usage.

The Front Wheel Quick Release Lever allows for both an open (release) position and a closed (secure)

position. When tightly closed, the Wheel Hub and Assembly are securely clamped to the Fork by the

action of the Front Wheel Quick Release Lever and Cam. When open, the Wheel Hub and Assembly

are no longer securely clamped to the Fork thus allowing the Wheel to easily come off the Fork. It is

critical for your safety, that the Front Wheel Quick Release Lever be tightly closed when riding.

The amount of clamping force is controlled by the Tension Adjusting Nut. Turning the Tension Adjusting

Nut clockwise while keeping the Lever from rotating increases clamping force; turning it counter

clockwise while keeping the Lever from rotating reduces clamping force. Less than half a turn of the

Tension Adjusting Nut can make the difference between safe clamping force and unsafe clamping force.

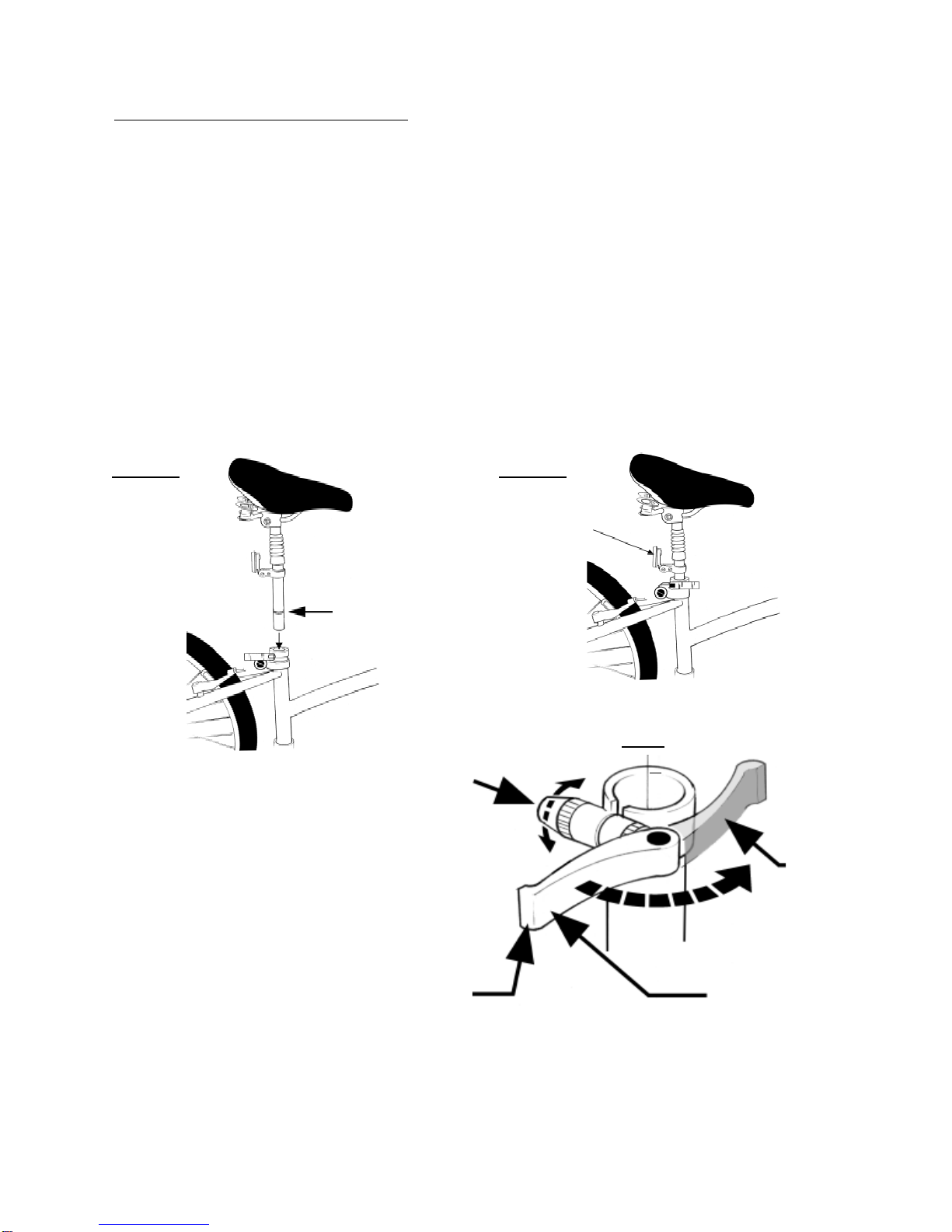

A) Now take the Front Wheel Quick Release and remove the Tension Adjusting Nut and one

Spring and slide the Front Wheel Quick Release Skewer through the Wheel Hub from the chain

side and replace the Spring and Tension Adjusting Nut so that the wide section of the Spring is

against the Tension Adjusting Nut. Important make sure the Lever is located in the round portion of

the cam bushing as shown in FIG. 14A.

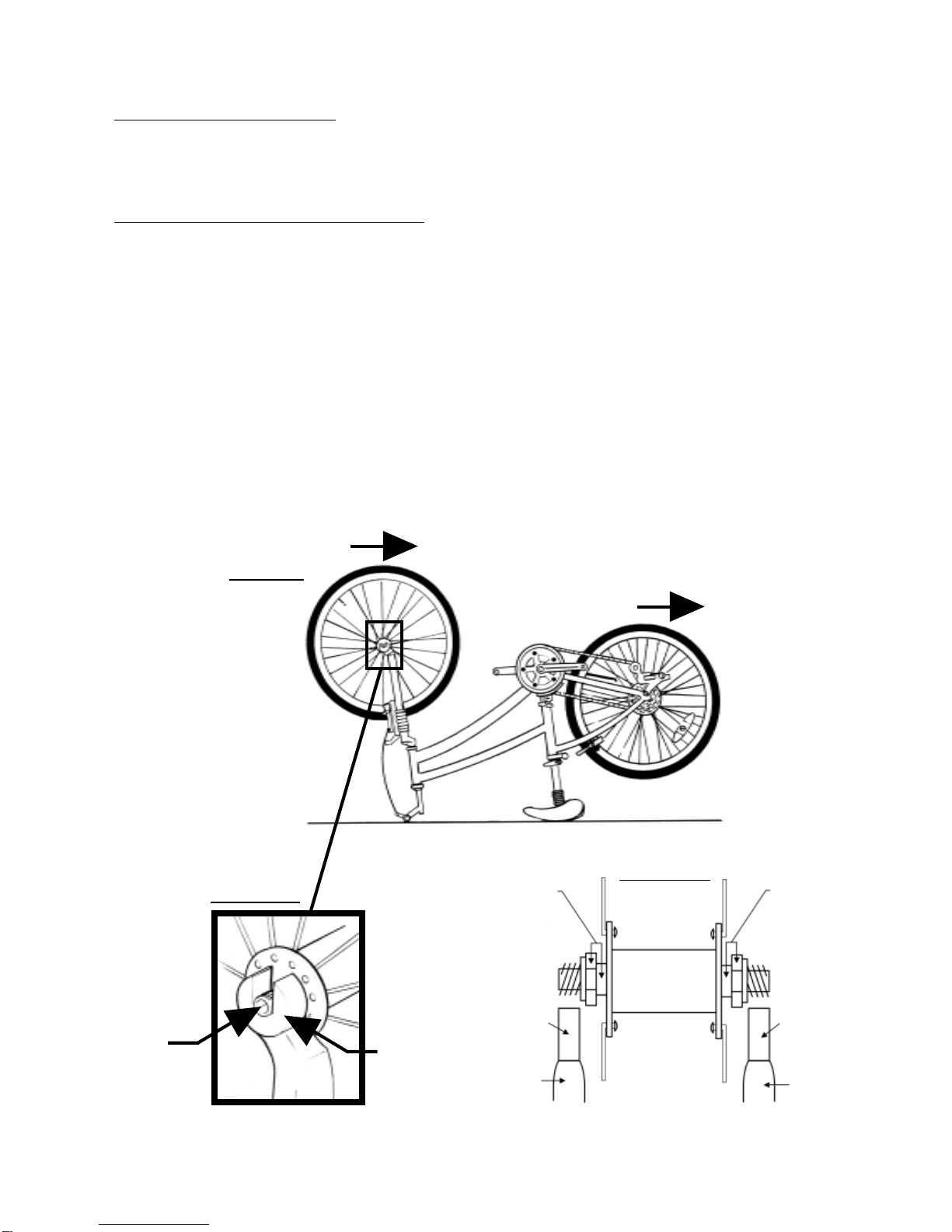

IMPORTANT: The following 2 figures (15 & 16) show the Front Wheel Fork as if you had

turned the bike over as recommended in Step 9 FIG 12.

FIG. 14

I

Lever Cam

FIG. 14A

Lever

Lever Cam

8

Skewer

Spring

Wheel Assembly

Fork Dropout

Tension

Adjusting

Nut

Lever

Fork Dropout

Lever Cam

Spring