2

Washer

broadens

as screw is

tightened.

Figure 2: Adjusting the clamp

brakes.

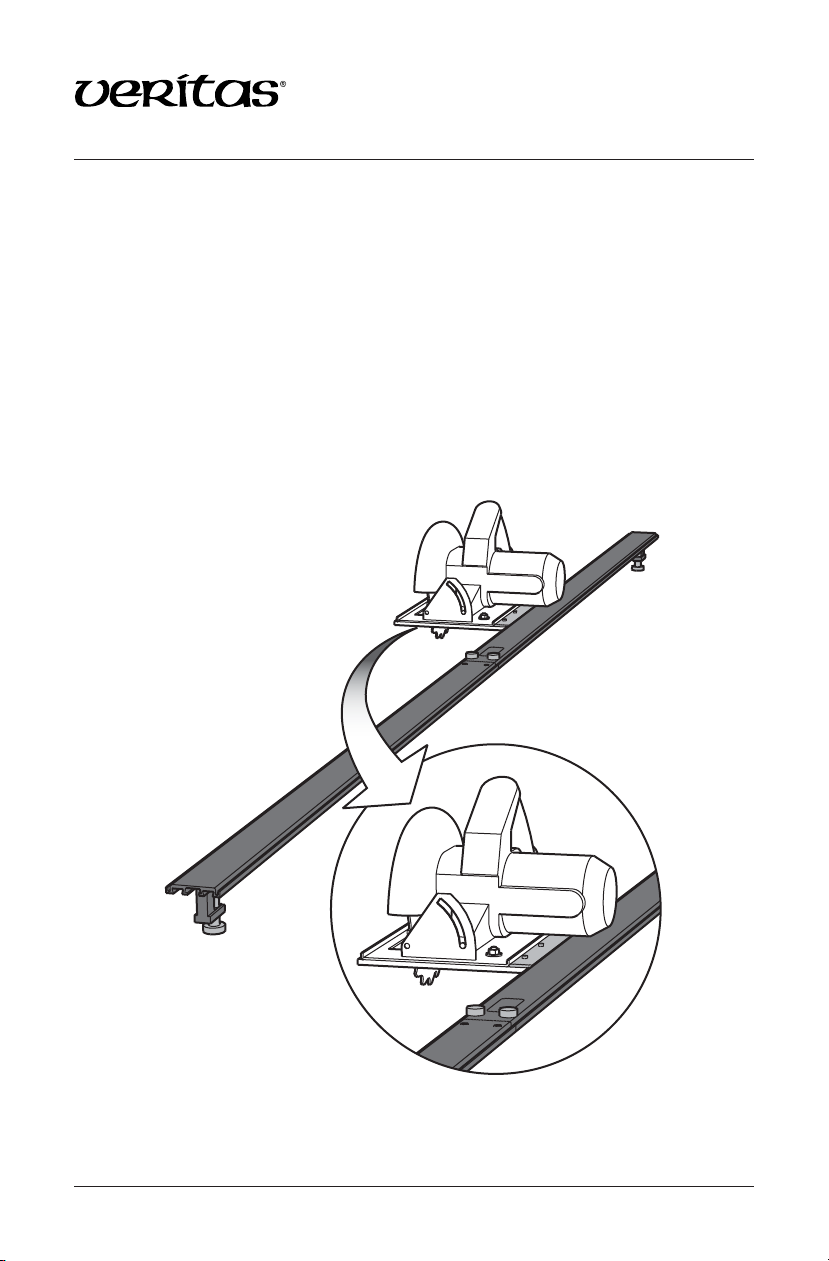

Figure 3: Setting the location of

the guide with a circular saw.

Cut Line

Safety Rules

These safety instructions are meant to complement those that came with your power

tool. We suggest that you reread those, in addition to these listed here before you begin

to use this product. To use this product safely, always follow both sets of safety and

general instructions.

1. Wear proper eye protection.

2. Wear proper hearing protection.

3. Remove adjusting keys before use.

4. Do not use this tool if it has been damaged in any way.

5. Clamp the workpiece firmly against the table or bench before cutting.

6. When mounting a circular saw to the traveller, make sure that the blade guard can

close properly.

7. Other than drilling mounting holes through the base plate, do not modify any

power tool in any way for use with this guide.

Set-Up

Each clamp includes a rubber washer that acts as

a brake, allowing you to place the clamps at any

location along the guide’s length, where they

will remain unless intentionally repositioned.

The rubber washers, when compressed by the

included screws, become broader, preventing

sliding. Adjust the screws such that the clamps

cannot slide down the track under their own

weight, but may be moved easily by hand. Two

spare rubber washers have been included should

they ever require replacement.

Main Guide

The main guide is 52"long and comes with the two clamps. This length allows the

guide to comfortably straddle the short (4') side of standard-sized sheet material. Mark

the cut line on the top of the sheet. Note that this does not have to be a continuous line;

it need only be marked at the near and far end.

Slide the clamps into the central T-slot, one at each

end of the beam and oriented so the open sides of

the clamp frames face each other. Place the guide

on top of the sheet, positioned so that it straddles

the sheet and is adjacent to the marks (normally

with the guide to the left of the marks), with the

clamps overhanging each end. With your power

tool unplugged and its base plate in contact with

the near edge of the guide, adjust the guide so the

tool will cut at the desired location, as illustrated

in Figure 3. Slide the clamp until it contacts the

edge of the sheet and tighten the clamp knob. Do

the same at the far end.